Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

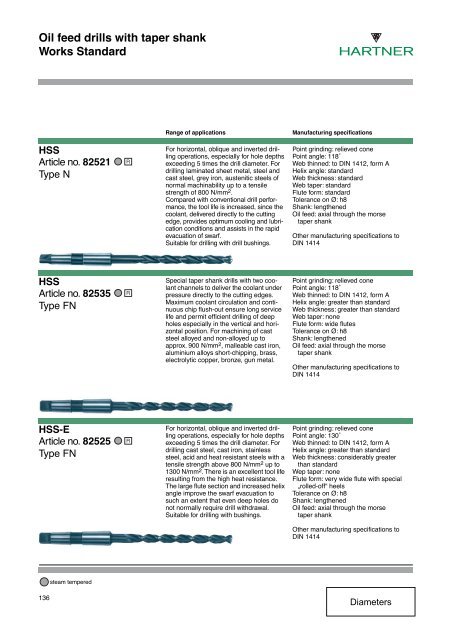

Oil feed <strong>drills</strong> <strong>with</strong> taper <strong>shank</strong><br />

Works Standard<br />

Range of applications<br />

Manufacturing specifications<br />

HSS<br />

Article no. 82521<br />

Type N<br />

R<br />

For horizontal, oblique and inverted drilling<br />

operations, especially for hole depths<br />

exceeding 5 times the drill diameter. For<br />

drilling laminated sheet metal, steel and<br />

cast steel, grey iron, austenitic steels of<br />

normal machinability up to a tensile<br />

strength of 800 N/mm 2 .<br />

Compared <strong>with</strong> conventional drill performance,<br />

the tool life is increased, since the<br />

coolant, delivered directly to the cutting<br />

edge, provides optimum cooling and lubrication<br />

conditions and assists in the rapid<br />

evacuation of swarf.<br />

Suitable for drilling <strong>with</strong> drill bushings.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: to <strong>DIN</strong> 1412, form A<br />

Helix angle: standard<br />

Web thickness: standard<br />

Web taper: standard<br />

Flute form: standard<br />

Tolerance on Ø: h8<br />

Shank: lengthened<br />

Oil feed: axial through the morse<br />

taper <strong>shank</strong><br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 1414<br />

HSS<br />

Article no. 82535<br />

Type FN<br />

R<br />

Special taper <strong>shank</strong> <strong>drills</strong> <strong>with</strong> two coolant<br />

channels to deliver the coolant under<br />

pressure directly to the cutting edges.<br />

Maximum coolant circulation and continuous<br />

chip flush-out ensure long service<br />

life and permit efficient drilling of deep<br />

holes especially in the vertical and horizontal<br />

position. For machining of cast<br />

steel alloyed and non-alloyed up to<br />

approx. 900 N/mm 2 , malleable cast iron,<br />

aluminium alloys short-chipping, brass,<br />

electrolytic copper, bronze, gun metal.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: to <strong>DIN</strong> 1412, form A<br />

Helix angle: greater than standard<br />

Web thickness: greater than standard<br />

Web taper: none<br />

Flute form: wide flutes<br />

Tolerance on Ø: h8<br />

Shank: lengthened<br />

Oil feed: axial through the morse<br />

taper <strong>shank</strong><br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 1414<br />

HSS-E<br />

Article no. 82525<br />

Type FN<br />

R<br />

For horizontal, oblique and inverted drilling<br />

operations, especially for hole depths<br />

exceeding 5 times the drill diameter. For<br />

drilling cast steel, cast iron, stainless<br />

steel, acid and heat resistant steels <strong>with</strong> a<br />

tensile strength above 800 N/mm 2 up to<br />

1300 N/mm 2 . There is an excellent tool life<br />

resulting from the high heat resistance.<br />

The large flute section and increased helix<br />

angle improve the swarf evacuation to<br />

such an extent that even deep holes do<br />

not normally require drill <strong>with</strong>drawal.<br />

Suitable for drilling <strong>with</strong> bushings.<br />

Point grinding: relieved cone<br />

Point angle: 130˚<br />

Web thinned: to <strong>DIN</strong> 1412, form A<br />

Helix angle: greater than standard<br />

Web thickness: considerably greater<br />

than standard<br />

Wep taper: none<br />

Flute form: very wide flute <strong>with</strong> special<br />

„rolled-off“ heels<br />

Tolerance on Ø: h8<br />

Shank: lengthened<br />

Oil feed: axial through the morse<br />

taper <strong>shank</strong><br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 1414<br />

steam tempered<br />

136