Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

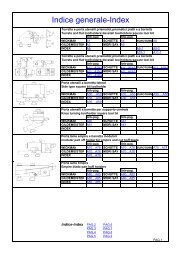

TS-Drills, 2-fluted, <strong>with</strong>out coolant ducts<br />

<strong>DIN</strong> 6537<br />

Range of applications<br />

Manufacturing specifications<br />

Solid carbide<br />

Article no. 89265<br />

Article no. 89405<br />

Type TS 100 F<br />

T<br />

F<br />

R<br />

R<br />

High-performance drill for the drilling of<br />

materials <strong>with</strong> a tensile strength of up to<br />

1400 N/mm 2 . Rigidity and resistance<br />

against wear and tear make this tool ideally<br />

suited for the drilling of hard, abrasive<br />

and hardened, as well as short- and<br />

long-chipping materials. Ideally suited<br />

materials are: Hastelloy, Monel, but also<br />

cast iron, brass, bronze, alloyed and<br />

unalloyed aluminium and magnesium,<br />

Ti and Ti-alloys and sintered powder<br />

metals.<br />

For drilling depths up to 3 x D.<br />

Advantages, suggestions:<br />

Highest speed and feed rates possible,<br />

high alignment accuracy <strong>with</strong> tight tolerance<br />

and excellent surface finish. Excellent<br />

self-centering qualities as well as<br />

producing short chips thanks to a concave<br />

cutting point geometry <strong>with</strong> special<br />

point grind and web thinning.<br />

Point grinding: relieved cone <strong>with</strong><br />

secondary flank<br />

Point angle: 140˚<br />

Web thinned: form F<br />

Helix angle: standard<br />

Web thickness: greater than standard<br />

Web taper: none<br />

Flute form: standard<br />

Tolerance on Ø: m7<br />

Shank: to <strong>DIN</strong> 6535 form HE,<br />

Tolerance h6<br />

Oil feed: spiral through the body<br />

Tool material: Solid carbide (K/P)<br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 6540<br />

Pre-conditions for use:<br />

Powerful machines. No play in spindle<br />

bearings. Alignment accurate tool holders.<br />

Max. concentricity error of clamped<br />

tools: 0.02 mm. Chatterfree, mechanical<br />

feeds. The tools are available <strong>with</strong>out<br />

whistle notch flat for the application in<br />

hydraulic chucks.<br />

l3<br />

d2<br />

d1<br />

l2<br />

l1<br />

167