Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

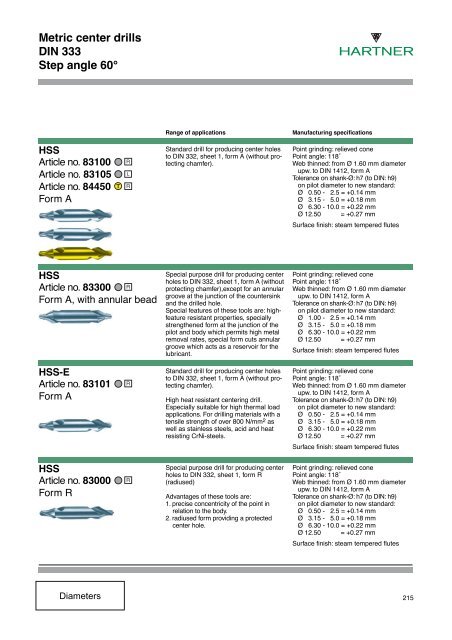

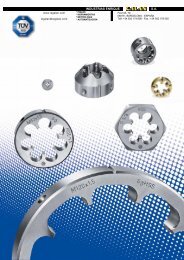

Metric center <strong>drills</strong><br />

<strong>DIN</strong> 333<br />

Step angle 60°<br />

Range of applications<br />

Manufacturing specifications<br />

HSS<br />

Article no. 83100<br />

Article no. 83105<br />

Article no. 84450<br />

Form A<br />

T<br />

R<br />

L<br />

R<br />

Standard drill for producing center holes<br />

to <strong>DIN</strong> 332, sheet 1, form A (<strong>with</strong>out protecting<br />

chamfer).<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: from Ø 1.60 mm diameter<br />

upw. to <strong>DIN</strong> 1412, form A<br />

Tolerance on <strong>shank</strong>-Ø: h7 (to <strong>DIN</strong>: h9)<br />

on pilot diameter to new standard:<br />

Ø 0.50 - 2.5 = +0.14 mm<br />

Ø 3.15 - 5.0 = +0.18 mm<br />

Ø 6.30 - 10.0 = +0.22 mm<br />

Ø 12.50 = +0.27 mm<br />

Surface finish: steam tempered flutes<br />

HSS<br />

Article no. 83300 R<br />

Form A, <strong>with</strong> annular bead<br />

Special purpose drill for producing center<br />

holes to <strong>DIN</strong> 332, sheet 1, form A (<strong>with</strong>out<br />

protecting chamfer),except for an annular<br />

groove at the junction of the countersink<br />

and the drilled hole.<br />

Special features of these tools are: highfeature<br />

resistant properties, specially<br />

strengthened form at the junction of the<br />

pilot and body which permits high metal<br />

removal rates, special form cuts annular<br />

groove which acts as a reservoir for the<br />

lubricant.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: from Ø 1.60 mm diameter<br />

upw. to <strong>DIN</strong> 1412, form A<br />

Tolerance on <strong>shank</strong>-Ø: h7 (to <strong>DIN</strong>: h9)<br />

on pilot diameter to new standard:<br />

Ø 1.00 - 2.5 = +0.14 mm<br />

Ø 3.15 - 5.0 = +0.18 mm<br />

Ø 6.30 - 10.0 = +0.22 mm<br />

Ø 12.50 = +0.27 mm<br />

Surface finish: steam tempered flutes<br />

HSS-E<br />

Article no. 83101<br />

Form A<br />

R<br />

Standard drill for producing center holes<br />

to <strong>DIN</strong> 332, sheet 1, form A (<strong>with</strong>out protecting<br />

chamfer).<br />

High heat resistant centering drill.<br />

Especially suitable for high thermal load<br />

applications. For drilling materials <strong>with</strong> a<br />

tensile strength of over 800 N/mm 2 as<br />

well as stainless steels, acid and heat<br />

resisting CrNi-steels.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: from Ø 1.60 mm diameter<br />

upw. to <strong>DIN</strong> 1412, form A<br />

Tolerance on <strong>shank</strong>-Ø: h7 (to <strong>DIN</strong>: h9)<br />

on pilot diameter to new standard:<br />

Ø 0.50 - 2.5 = +0.14 mm<br />

Ø 3.15 - 5.0 = +0.18 mm<br />

Ø 6.30 - 10.0 = +0.22 mm<br />

Ø 12.50 = +0.27 mm<br />

Surface finish: steam tempered flutes<br />

HSS<br />

Article no. 83000<br />

Form R<br />

R<br />

Special purpose drill for producing center<br />

holes to <strong>DIN</strong> 332, sheet 1, form R<br />

(radiused)<br />

Advantages of these tools are:<br />

1. precise concentricity of the point in<br />

relation to the body.<br />

2. radiused form providing a protected<br />

center hole.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: from Ø 1.60 mm diameter<br />

upw. to <strong>DIN</strong> 1412, form A<br />

Tolerance on <strong>shank</strong>-Ø: h7 (to <strong>DIN</strong>: h9)<br />

on pilot diameter to new standard:<br />

Ø 0.50 - 2.5 = +0.14 mm<br />

Ø 3.15 - 5.0 = +0.18 mm<br />

Ø 6.30 - 10.0 = +0.22 mm<br />

Ø 12.50 = +0.27 mm<br />

Surface finish: steam tempered flutes<br />

215