Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

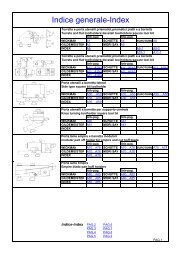

Shank designs for Morse taper <strong>with</strong> flat tang<br />

to <strong>DIN</strong> 228 form B<br />

<strong>shank</strong> to<br />

<strong>DIN</strong> 228 form B<br />

size<br />

tol.<br />

a zone b d 1 d 2<br />

≈<br />

d 5<br />

≈<br />

d 6<br />

max.<br />

l 6<br />

0<br />

-1<br />

l 7<br />

max.<br />

r 2<br />

max.<br />

r 3<br />

≈<br />

α<br />

2<br />

MT 0 3.0<br />

MT 1 3.5<br />

MT 2 5.0<br />

MT 3 5.0<br />

MK 4 6.5<br />

MT 5 6.5<br />

MT 6 8.0<br />

-1.2<br />

0<br />

-1.4<br />

0<br />

-1.4<br />

0<br />

-1.7<br />

0<br />

-1.9<br />

0<br />

-1.9<br />

0<br />

-2.3<br />

0<br />

3.9 9.045 9.2 6.1 6.0 56.5 10.5 4 1.0 1°29‘27‘‘<br />

5.2 12.065 12.2 9.0 8.7 62.0 13.5 5 1.2 1°25‘43‘‘<br />

6.3 17.780 18.0 14.0 13.5 75.0 16.0 5 1.6 1°25‘50‘‘<br />

7.9 23.825 24.1 19.1 18.5 94.0 20.0 7 2.0 1°26‘16‘‘<br />

11.9 31.267 31.6 25.2 24.5 117.5 24.0 9 2.5 1°29‘15‘‘<br />

15.9 44.399 44.7 36.5 35.7 149.5 29.0 10 3.0 1°30‘26‘‘<br />

19.0 63.348 63.8 52.4 51.0 210.0 40.0 13 4.0 1°29‘36‘‘<br />

≈ 0.25 x 45°<br />

or R 0.3*)<br />

≈ 0.25 x 45°<br />

or R 0.3*)<br />

Twist drill definition (HSS and carbide)<br />

Type application rake<br />

angle<br />

centre hole acc. to <strong>DIN</strong> 332, part 1, form B or R*)<br />

*) manufacturer’s option<br />

point<br />

angle<br />

point<br />

grind<br />

N<br />

H<br />

W<br />

FN<br />

FN 500<br />

FU 500<br />

FW<br />

EN<br />

S<br />

IS<br />

V<br />

TS 3<br />

TS 80 U<br />

TS 100 F<br />

TS 100 U<br />

TS 150 GG<br />

for normal machining materials<br />

(e.g. steel, cast steel, grey casting)<br />

for hard, short-chipping materials<br />

(e.g. brass, bronze, elektron metal)<br />

for soft, long-chipping materials<br />

(e.g. Al-alloys, copper)<br />

for normal machining materials<br />

<strong>with</strong> extra deep holes<br />

for long-chipping, tough materials (e.g. high alloyed steels,<br />

heat treatable and case hardened steels)<br />

for universal applications (e.g. alloyed and unalloyed steels<br />

up to 800 mm2)<br />

for soft, long-chipping materials<br />

<strong>with</strong> extra deep holes<br />

for short-chipping materials<br />

up to approx. 1200 N/mm2<br />

for tough difficult to machine materials<br />

(e.g. stainless and heat-resistant steels)<br />

for tough, stainless, acid and<br />

heat-resistant steels<br />

for tough difficult to machine materials<br />

(e.g. spring steels)<br />

for the production of holes<br />

<strong>with</strong> positional and dimensional accuracy<br />

for universal applications<br />

(e.g. GG, GGG, steel up to approx. 1000 N/mm2)<br />

for long-chipping, tough mat. up to approx. 1400 N/mm2<br />

(e.g. heat treatable steels, high-alloyed steels)<br />

for steels up to approx. 1000 N/mm2,<br />

universal applications<br />

for grey cast iron, spheroidal graphite iron,<br />

black malleable cast iron<br />

20°-30° 118° relieved cone<br />

standard point grind<br />

12°-16° 118° relieved cone<br />

standard point grind<br />

35°-40° 130° relieved cone<br />

standard point grind<br />

35° 130° relieved cone<br />

web-thinned chisel edge<br />

20° - 30° 130° relieved cone<br />

special point grind<br />

35° 118° 2-facet<br />

special point grind<br />

35°-40° 130° relieved cone<br />

standard point grind<br />

20°-30° 130° relieved cone<br />

<strong>with</strong> web thinned from A<br />

35° 130° relieved cone<br />

standard point grind<br />

40° 130° relieved cone<br />

standard point grind<br />

20°-30° 130° relieved cone<br />

web-thinned chisel edge<br />

28° 150° facet grinding<br />

20°-30° 140° relieved cone<br />

<strong>with</strong> web thinned from F<br />

20°-30° 140° relieved cone<br />

<strong>with</strong> web thinned from F<br />

25°-35° 140° relieved cone<br />

<strong>with</strong> web thinned from F<br />

0° (<strong>straight</strong><br />

fluted)<br />

120° relieved cone<br />

<strong>with</strong> web thinned from GG<br />

high speed cutting <strong>drills</strong><br />

tungsten carbide <strong>drills</strong><br />

255