Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

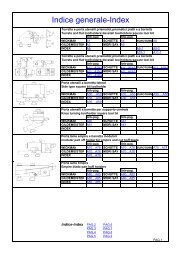

TS-Drills, 2-fluted, <strong>with</strong> coolant ducts<br />

<strong>DIN</strong> 6537<br />

Range of applications<br />

Manufacturing specifications<br />

Solid carbide<br />

Article no. 89412<br />

Article no. 89416<br />

Type TS 100 U<br />

F<br />

F<br />

R<br />

R<br />

For drilling of long and short-chipping<br />

materials such as structural and case<br />

hardened steels, cast steels, heat-treatable<br />

steels and alloyed steels <strong>with</strong> a<br />

tensile strength of up to 1200 N/mm 2 ,<br />

including carbon steels, bronze, cast iron<br />

and high-alloyed AlSi-alloys.<br />

For drilling depths up to ≤ 7 x D.<br />

Point grinding: relieved cone <strong>with</strong><br />

secondary flank<br />

Point angle: 140˚<br />

Web thinned: TS-special<br />

Helix angle: standard<br />

Web thickness: greater than standard<br />

Web taper: none<br />

Flute form: standard<br />

Tolerance on Ø: m7<br />

Shank: to <strong>DIN</strong> 6535<br />

form HA: article no. 89412,<br />

form HE: article no. 89416,<br />

Tolerance h6<br />

Oil feed: spiral through the body<br />

Advantages, suggestions:<br />

Highest speed and feed rates possible,<br />

high alignment accuracy <strong>with</strong> tight tolerance<br />

and excellent surface finish. Excellent<br />

self-centering qualities as well as<br />

producing short chips thanks to a concave<br />

cutting point geometry <strong>with</strong> special<br />

point grind and web thinning.<br />

Tool material: Solid carbide (K/P)<br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 6540<br />

Pre-conditions for use:<br />

Powerful machines. No play in spindle<br />

bearings. Alignment accurate tool holders.<br />

Max. concentricity error of clamped<br />

tools: 0.02 mm. Chatterfree, mechanical<br />

feeds. The tools are available <strong>with</strong>out<br />

whistle notch flat for the application in<br />

hydraulic chucks.<br />

l3<br />

d2<br />

d1<br />

l2<br />

l1<br />

177