Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

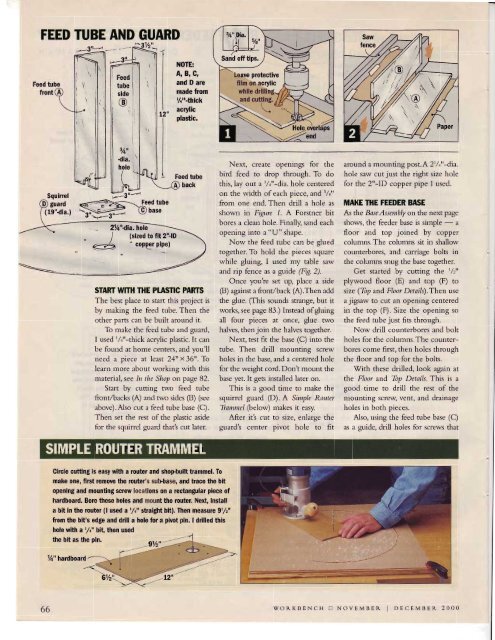

FEED TUBE AND GUARD<br />

Feed tube<br />

front<br />

NOTE:<br />

A, B, C,<br />

and Il arc<br />

made from<br />

%"-thick<br />

acrylic<br />

plastic.<br />

Squlrrel<br />

guard<br />

Feed tube<br />

back<br />

Next, create openings for the<br />

bird feed to drop through. To do<br />

this, lay out a '/."-dia. hole centered<br />

on the width of each piece, and '/r"<br />

from one end. Then drill a hole as<br />

shown in Figure 1. A Forstner bit<br />

bores a clean hole. Finally, sand each<br />

opening into a "U" shaPe.<br />

Now the feed tube can be glued<br />

together. To hold the pieces square<br />

while gluing, I used my table saw<br />

and rip fence as a guide (Fig.2).<br />

Once youte set up, place a side<br />

@) apinst a front/back (A).Then add<br />

START WMI <strong>ft</strong>E PLASNG PARTS<br />

The best place to start this project is the glue. (This sounds strange, but it<br />

by making the feed tube. Then the works, see page 83.) Instead of gluing<br />

other parts can be built around it. all four pieces at once, glue two<br />

To make the feed tube and guard, halves, then join the halves together.<br />

I used '/*"-thick acrylic plastic. It can Next, test fit the base (C) into the<br />

be found at home centers, and You'll tube. Then drill mounting screw<br />

need a piece at least 24" x36". To holes in the base, and a centered hole<br />

learn more about working with this for the weight cord. Dont mount the<br />

material, see In the Shop on Page 82. base yet. [t gets installed later on.<br />

Start by <strong>cutting</strong> nvo feed tube This is a good time to make the<br />

front/backs (A) and two sides (B) G.e squirrel guard (D). A Simple Routet<br />

above).Also cut a feed tube base (C). Tiammel (below) makes it easy.<br />

Then set the rest of the plastic aside A<strong>ft</strong>er it's cut to size, enlarge the<br />

for the squirrel guard that's cut later. guardt center pivot hole to fit<br />

around a mounting post.A 2'/i'-dia.<br />

hole saw cut just the right size hole<br />

for the 2"-ID copper piPe I used.<br />

MAKE IHE FEEDER BASE<br />

As the Basez4ssembly on the next page<br />

shows, the feeder base is simPle - a<br />

floor and top joined by coPPer<br />

columns. The columns sit in shallow<br />

counterbores, and carriage bolts in<br />

the columns snug the base together.<br />

Get started by <strong>cutting</strong> the 1/2"<br />

plywood floor (E) and toP (F) to<br />

size (Tbp and Floor Deralls).Then use<br />

ajigsaw to cut an oPening centered<br />

in the top (F). Size the oPening so<br />

the feed tube just fits through.<br />

Now drill counterbores and bolt<br />

holes for the columns.The counterbores<br />

come first, then holes through<br />

the floor and top for the bolts.<br />

With these drilled, look again at<br />

the Floor and Tbp Details. This is a<br />

good time to drill the rest of the<br />

mounting screw vent, and drainage<br />

holes in both pieces.<br />

Also, using the feed tube base (C)<br />

as a guide, drill holes for screws that<br />

Clrcle cuttlng ls easy wlth a loutel and shoPbullt trammel. To<br />

make one, flrst remove the router' sutsbase' and trace the blt<br />

openlng and mountlng screw locatlons on a lectangular plece of<br />

hardboard. Bore these holes and mounthe router. Next, lnstall<br />

a blt ln the router (l used a %" stralght blt). Ihen measure 9%"<br />

from the bit's edge and dilll a hole for a pivot pln. I drllled thls<br />

hole wlth xr/e" blt, then used<br />

the blt as the pln.<br />

%" hardboard<br />

66<br />

woRKBENcH tr NovEMBER I<br />

DECEMBER 2000

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)