Download Manual - Silvan Australia

Download Manual - Silvan Australia

Download Manual - Silvan Australia

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

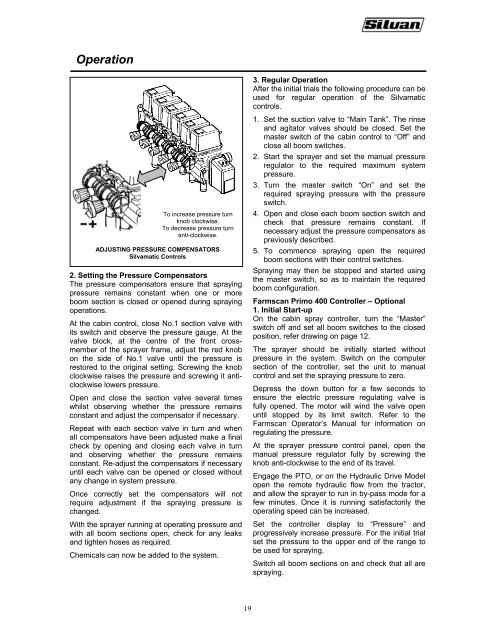

Operation<br />

To increase pressure turn<br />

knob clockwise.<br />

To decrease pressure turn<br />

anti-clockwise.<br />

ADJUSTING PRESSURE COMPENSATORS<br />

Silvamatic Controls<br />

2. Setting the Pressure Compensators<br />

The pressure compensators ensure that spraying<br />

pressure remains constant when one or more<br />

boom section is closed or opened during spraying<br />

operations.<br />

At the cabin control, close No.1 section valve with<br />

its switch and observe the pressure gauge. At the<br />

valve block, at the centre of the front crossmember<br />

of the sprayer frame, adjust the red knob<br />

on the side of No.1 valve until the pressure is<br />

restored to the original setting. Screwing the knob<br />

clockwise raises the pressure and screwing it anticlockwise<br />

lowers pressure.<br />

Open and close the section valve several times<br />

whilst observing whether the pressure remains<br />

constant and adjust the compensator if necessary.<br />

Repeat with each section valve in turn and when<br />

all compensators have been adjusted make a final<br />

check by opening and closing each valve in turn<br />

and observing whether the pressure remains<br />

constant. Re-adjust the compensators if necessary<br />

until each valve can be opened or closed without<br />

any change in system pressure.<br />

Once correctly set the compensators will not<br />

require adjustment if the spraying pressure is<br />

changed.<br />

With the sprayer running at operating pressure and<br />

with all boom sections open, check for any leaks<br />

and tighten hoses as required.<br />

Chemicals can now be added to the system.<br />

3. Regular Operation<br />

After the initial trials the following procedure can be<br />

used for regular operation of the Silvamatic<br />

controls.<br />

1. Set the suction valve to “Main Tank”. The rinse<br />

and agitator valves should be closed. Set the<br />

master switch of the cabin control to “Off” and<br />

close all boom switches.<br />

2. Start the sprayer and set the manual pressure<br />

regulator to the required maximum system<br />

pressure.<br />

3. Turn the master switch “On” and set the<br />

required spraying pressure with the pressure<br />

switch.<br />

4. Open and close each boom section switch and<br />

check that pressure remains constant. If<br />

necessary adjust the pressure compensators as<br />

previously described.<br />

5. To commence spraying open the required<br />

boom sections with their control switches.<br />

Spraying may then be stopped and started using<br />

the master switch, so as to maintain the required<br />

boom configuration.<br />

Farmscan Primo 400 Controller – Optional<br />

1. Initial Start-up<br />

On the cabin spray controller, turn the “Master”<br />

switch off and set all boom switches to the closed<br />

position, refer drawing on page 12.<br />

The sprayer should be initially started without<br />

pressure in the system. Switch on the computer<br />

section of the controller, set the unit to manual<br />

control and set the spraying pressure to zero.<br />

Depress the down button for a few seconds to<br />

ensure the electric pressure regulating valve is<br />

fully opened. The motor will wind the valve open<br />

until stopped by its limit switch. Refer to the<br />

Farmscan Operator’s <strong>Manual</strong> for information on<br />

regulating the pressure.<br />

At the sprayer pressure control panel, open the<br />

manual pressure regulator fully by screwing the<br />

knob anti-clockwise to the end of its travel.<br />

Engage the PTO, or on the Hydraulic Drive Model<br />

open the remote hydraulic flow from the tractor,<br />

and allow the sprayer to run in by-pass mode for a<br />

few minutes. Once it is running satisfactorily the<br />

operating speed can be increased.<br />

Set the controller display to “Pressure” and<br />

progressively increase pressure. For the initial trial<br />

set the pressure to the upper end of the range to<br />

be used for spraying.<br />

Switch all boom sections on and check that all are<br />

spraying.<br />

19