Download Manual - Silvan Australia

Download Manual - Silvan Australia

Download Manual - Silvan Australia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

General Spraying Information<br />

When to Spray<br />

Results will be best when the wind speed is low,<br />

the temperature is low and the relative humidity is<br />

high. An ideal time is at sun up when these<br />

conditions are most likely to apply.<br />

Droplet Size<br />

Although more research is needed to define which<br />

is the optimum droplet size collected by particular<br />

targets, certain generalisations can be made. The<br />

trend with herbicides has been to apply large<br />

droplets (250 microns) to reduce the risk of drift but<br />

smaller droplets are often the most effective as<br />

shown by the following table.<br />

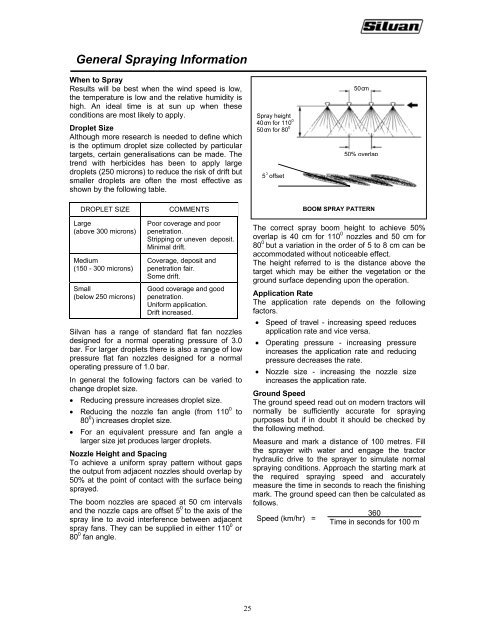

5 0 offset<br />

50 c m<br />

Spray height<br />

40 cm for 110 0<br />

50 cm for 80 0 50% overlap<br />

DROPLET SIZE<br />

COMMENTS<br />

BOOM SPRAY PATTERN<br />

Large<br />

(above 300 microns)<br />

Medium<br />

(150 - 300 microns)<br />

Small<br />

(below 250 microns)<br />

Poor coverage and poor<br />

penetration.<br />

Stripping or uneven deposit.<br />

Minimal drift.<br />

Coverage, deposit and<br />

penetration fair.<br />

Some drift.<br />

Good coverage and good<br />

penetration.<br />

Uniform application.<br />

Drift increased.<br />

<strong>Silvan</strong> has a range of standard flat fan nozzles<br />

designed for a normal operating pressure of 3.0<br />

bar. For larger droplets there is also a range of low<br />

pressure flat fan nozzles designed for a normal<br />

operating pressure of 1.0 bar.<br />

In general the following factors can be varied to<br />

change droplet size.<br />

• Reducing pressure increases droplet size.<br />

• Reducing the nozzle fan angle (from 110 0 to<br />

80 0 ) increases droplet size.<br />

• For an equivalent pressure and fan angle a<br />

larger size jet produces larger droplets.<br />

Nozzle Height and Spacing<br />

To achieve a uniform spray pattern without gaps<br />

the output from adjacent nozzles should overlap by<br />

50% at the point of contact with the surface being<br />

sprayed.<br />

The boom nozzles are spaced at 50 cm intervals<br />

and the nozzle caps are offset 5 0 to the axis of the<br />

spray line to avoid interference between adjacent<br />

spray fans. They can be supplied in either 110 0 or<br />

80 0 fan angle.<br />

The correct spray boom height to achieve 50%<br />

overlap is 40 cm for 110 0 nozzles and 50 cm for<br />

80 0 but a variation in the order of 5 to 8 cm can be<br />

accommodated without noticeable effect.<br />

The height referred to is the distance above the<br />

target which may be either the vegetation or the<br />

ground surface depending upon the operation.<br />

Application Rate<br />

The application rate depends on the following<br />

factors.<br />

• Speed of travel - increasing speed reduces<br />

application rate and vice versa.<br />

• Operating pressure - increasing pressure<br />

increases the application rate and reducing<br />

pressure decreases the rate.<br />

• Nozzle size - increasing the nozzle size<br />

increases the application rate.<br />

Ground Speed<br />

The ground speed read out on modern tractors will<br />

normally be sufficiently accurate for spraying<br />

purposes but if in doubt it should be checked by<br />

the following method.<br />

Measure and mark a distance of 100 metres. Fill<br />

the sprayer with water and engage the tractor<br />

hydraulic drive to the sprayer to simulate normal<br />

spraying conditions. Approach the starting mark at<br />

the required spraying speed and accurately<br />

measure the time in seconds to reach the finishing<br />

mark. The ground speed can then be calculated as<br />

follows.<br />

360<br />

Speed (km/hr) =<br />

Time in seconds for 100 m<br />

25