PDF EN - Tornos

PDF EN - Tornos

PDF EN - Tornos

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

to be shortened, while offering the option of finishing<br />

complex parts on the machine. As the visual<br />

appearance of the parts is becoming more and more<br />

important, ejecting them in bulk is now sometimes<br />

not possible. It must be ensured that the parts will<br />

not be damaged when conveyed from the machining<br />

area. To ensure this, <strong>Tornos</strong> engineers are also<br />

offering a solution which actually integrates a part<br />

gripper inside the turning machine itself. This grips<br />

each part after it is finished and places it in a pallet,<br />

or in another system as chosen by the customer.<br />

The parts can then be conveyed directly to a washing<br />

machine, for example.<br />

The gripper and palletisation system is 100 % integrated<br />

into the machine, it is not an “add-on” system<br />

which has “sprung up” around the edges, but a<br />

genuine built-in component inside the machine.<br />

Two machines in one<br />

These products with eight spindles offer yet another<br />

additional benefit compared to turning machines<br />

with six spindles as they offer the ability to work in<br />

2X4 mode (dual cycle). With a single machine, it is<br />

possible to produce relatively straightforward parts<br />

in dual production (up to 40 parts / min) and very<br />

complex parts in standard mode. The customer gets<br />

two products in one, and can choose between four<br />

and eight spindles, depending on the day’s requirements.<br />

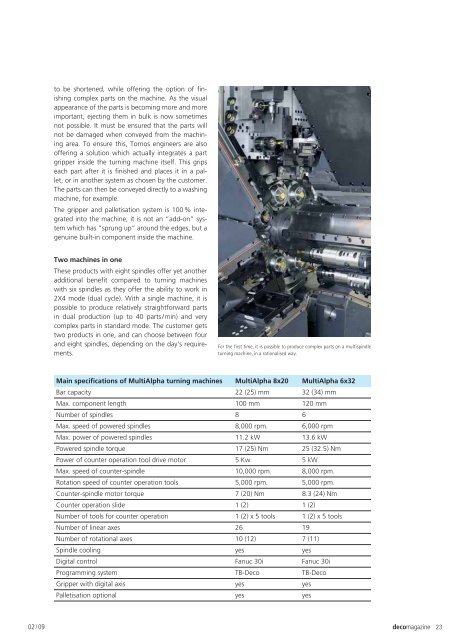

For the first time, it is possible to produce complex parts on a multispindle<br />

turning machine, in a rationalised way.<br />

Main specifications of MultiAlpha turning machines MultiAlpha 8x20 MultiAlpha 6x32<br />

Bar capacity 22 (25) mm 32 (34) mm<br />

Max. component length 100 mm 120 mm<br />

Number of spindles 8 6<br />

Max. speed of powered spindles 8,000 rpm. 6,000 rpm<br />

Max. power of powered spindles 11.2 kW 13.6 kW<br />

Powered spindle torque 17 (25) Nm 25 (32.5) Nm<br />

Power of counter operation tool drive motor 5 Kw 5 kW<br />

Max. speed of counter-spindle 10,000 rpm. 8,000 rpm.<br />

Rotation speed of counter operation tools 5,000 rpm. 5,000 rpm.<br />

Counter-spindle motor torque 7 (20) Nm 8.3 (24) Nm<br />

Counter operation slide 1 (2) 1 (2)<br />

Number of tools for counter operation 1 (2) x 5 tools 1 (2) x 5 tools<br />

Number of linear axes 26 19<br />

Number of rotational axes 10 (12) 7 (11)<br />

Spindle cooling yes yes<br />

Digital control Fanuc 30i Fanuc 30i<br />

Programming system TB-Deco TB-Deco<br />

Gripper with digital axis yes yes<br />

Palletisation optional yes yes<br />

02 / 09 decomagazine 23