Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THERMAL ANALYSIS ISSUE 2009<br />

Calorimetry as a<br />

Process Analytical Tool<br />

for micronising<br />

pharmaceuticals<br />

Simon Gaisford, Lecturer in Pharmaceutics, University of London<br />

Drug delivery via the pulmonary route is becoming increasingly popular, but brings a unique set of<br />

formulation challenges. In particular the small particle sizes (between 2-5 μm) required to facilitate<br />

deposition in the lung frequently mean that size-reduction steps (such as milling) are required<br />

during processing of constituents (usually the active principal) prior to formulation.<br />

Typically either ball mills or air-jet<br />

mills are employed to achieve<br />

the desired reduction in particle<br />

size. In the former case ceramic or<br />

metal balls are placed in a container<br />

with the sample and whole apparatus<br />

is rotated; the size, weight and number<br />

of balls can be varied as can the<br />

number of revolutions per minute<br />

and the total milling <strong>time</strong>. In the latter<br />

case compressed air is used to<br />

agitate particles, causing size reduction<br />

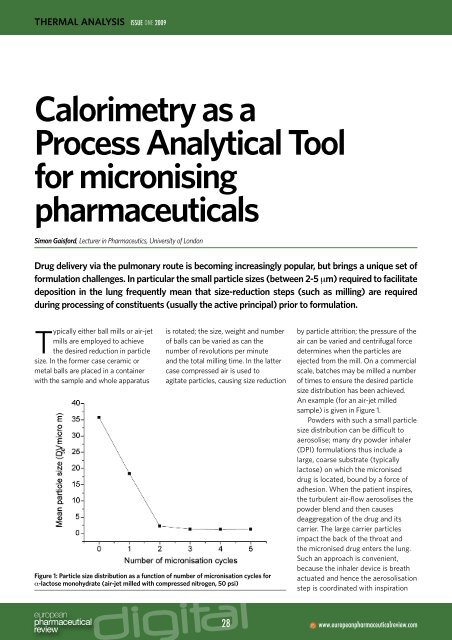

Figure 1: Particle size distribution as a function of number of micronisation cycles for<br />

α-lactose monohydrate (air-jet milled with compressed nitrogen, 50 psi)<br />

by particle attrition; the pressure of the<br />

air can be varied and centrifugal force<br />

determines when the particles are<br />

ejected from the mill. On a commercial<br />

scale, batches may be milled a number<br />

of <strong>time</strong>s to ensure the desired particle<br />

size distribution has been achieved.<br />

An example (for an air-jet milled<br />

sample) is given in Figure 1.<br />

Powders with such a small particle<br />

size distribution can be difficult to<br />

aerosolise; many dry powder inhaler<br />

(DPI) formulations thus include a<br />

large, coarse substrate (typically<br />

lactose) on which the micronised<br />

drug is located, bound by a force of<br />

adhesion. When the patient inspires,<br />

the turbulent air-flow aerosolises the<br />

powder blend and then causes<br />

deaggregation of the drug and its<br />

carrier. The large carrier particles<br />

impact the back of the throat and<br />

the micronised drug enters the lung.<br />

Such an approach is convenient,<br />

because the inhaler device is breath<br />

actuated and hence the aerosolisation<br />

step is coordinated with inspiration<br />

28<br />

www.europeanpharmaceuticalreview.com