Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THERMAL ANALYSIS ISSUE 2009<br />

system, TA Instruments LLC) was<br />

employed to quantify the extent of<br />

any disorder.<br />

The use of IGPC for amorphous<br />

content has become popular and the<br />

technique offers many advantages 6 .<br />

Briefly, in a gas-perfusion experiment<br />

the sample is held in an ampoule<br />

while a carrier gas flows over the<br />

sample. The relative vapour pressure<br />

(RVP) of the gas is controlled by<br />

proportional mixing of dry (0% RVP)<br />

and wet (100% RVP) gas streams.<br />

The system can thus be programmed<br />

to follow a specific RVP program.<br />

IGPC is convenient for quantifying<br />

amorphous material; the sample is<br />

held dry and allowed to reach thermal<br />

equilibrium. The RVP is then<br />

increased (usually to ca. 90%) which<br />

results in solvent uptake by the<br />

sample. This plasticises the sample,<br />

lowering the glass transition<br />

temperature and causing<br />

recrystallisation. The RVP is then<br />

returned to zero, which dries the<br />

sample. Subtraction of the areas<br />

under the wetting and drying peaks<br />

thus indicates the presence of any<br />

irreversible events.<br />

A calibration curve of amorphous<br />

content versus heat of crystallisation<br />

was prepared by mixing proportional<br />

mass ratios of the crystalline and<br />

amorphous SS samples. Full<br />

experimental details are available<br />

upon request.<br />

The calibration curve obtained of<br />

SS amorphous content versus<br />

measured heat was linear (see<br />

Figure 2 on page 29). It was thus<br />

possible to use the data to quantify<br />

extents of disorder in milled SS<br />

samples, although it should be noted<br />

that the use of this type of calibration<br />

curve has some limitations 6,7 .<br />

Principally, the material used to<br />

prepare the calibration curve (a<br />

mixture of wholly amorphous and<br />

wholly crystalline particles) is<br />

physically distinct from the study<br />

material, which in this case will have<br />

disordered regions (that is, a<br />

combination of crystal dislocations<br />

and amorphous areas) forming a<br />

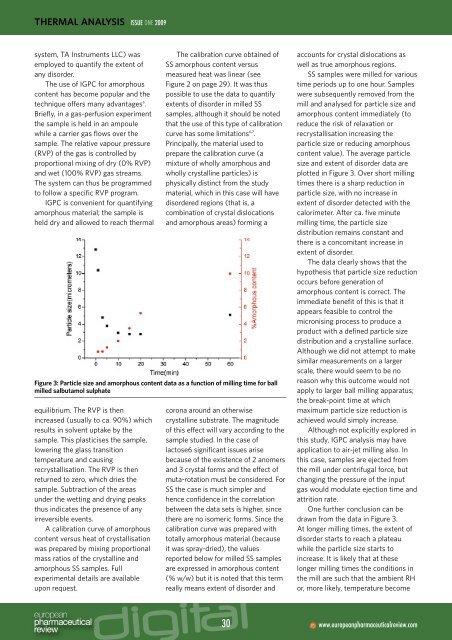

Figure 3: Particle size and amorphous content data as a function of milling <strong>time</strong> for ball<br />

milled salbutamol sulphate<br />

corona around an otherwise<br />

crystalline substrate. The magnitude<br />

of this effect will vary according to the<br />

sample studied. In the case of<br />

lactose6 significant issues arise<br />

because of the existence of 2 anomers<br />

and 3 crystal forms and the effect of<br />

muta-rotation must be considered. For<br />

SS the case is much simpler and<br />

hence confidence in the correlation<br />

between the data sets is higher, since<br />

there are no isomeric forms. Since the<br />

calibration curve was prepared with<br />

totally amorphous material (because<br />

it was spray-dried), the values<br />

reported below for milled SS samples<br />

are expressed in amorphous content<br />

(% w/w) but it is noted that this term<br />

really means extent of disorder and<br />

accounts for crystal dislocations as<br />

well as true amorphous regions.<br />

SS samples were milled for various<br />

<strong>time</strong> periods up to one hour. Samples<br />

were subsequently removed from the<br />

mill and analysed for particle size and<br />

amorphous content immediately (to<br />

reduce the risk of relaxation or<br />

recrystallisation increasing the<br />

particle size or reducing amorphous<br />

content value). The average particle<br />

size and extent of disorder data are<br />

plotted in Figure 3. Over short milling<br />

<strong>time</strong>s there is a sharp reduction in<br />

particle size, with no increase in<br />

extent of disorder detected with the<br />

calorimeter. After ca. five minute<br />

milling <strong>time</strong>, the particle size<br />

distribution remains constant and<br />

there is a concomitant increase in<br />

extent of disorder.<br />

The data clearly shows that the<br />

hypothesis that particle size reduction<br />

occurs before generation of<br />

amorphous content is correct. The<br />

immediate benefit of this is that it<br />

appears feasible to control the<br />

micronising process to produce a<br />

product with a defined particle size<br />

distribution and a crystalline surface.<br />

Although we did not attempt to make<br />

similar measurements on a larger<br />

scale, there would seem to be no<br />

reason why this outcome would not<br />

apply to larger ball milling apparatus;<br />

the break-point <strong>time</strong> at which<br />

maximum particle size reduction is<br />

achieved would simply increase.<br />

Although not explicitly explored in<br />

this study, IGPC analysis may have<br />

application to air-jet milling also. In<br />

this case, samples are ejected from<br />

the mill under centrifugal force, but<br />

changing the pressure of the input<br />

gas would modulate ejection <strong>time</strong> and<br />

attrition rate.<br />

One further conclusion can be<br />

drawn from the data in Figure 3.<br />

At longer milling <strong>time</strong>s, the extent of<br />

disorder starts to reach a plateau<br />

while the particle size starts to<br />

increase. It is likely that at these<br />

longer milling <strong>time</strong>s the conditions in<br />

the mill are such that the ambient RH<br />

or, more likely, temperature become<br />

30<br />

www.europeanpharmaceuticalreview.com