Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SUBSCRIBE<br />

ISSUE<br />

2009 PAT<br />

especially the fundamentally different<br />

way of describing the steps of the<br />

procedures compared to a typical<br />

laboratory manual. Unlike a SOP the<br />

functions of the steps are separated<br />

and thoroughly investigated in terms<br />

of effects on the procedural steps.<br />

Note also the influence of the<br />

active environment. The hESC process<br />

is subject to longterm exposure of<br />

contaminating disturbances from the<br />

environment – not possible to foresee,<br />

but to counteract. The biological<br />

variation, which is so important to<br />

measure or detect is included in the<br />

active environment.<br />

The depiction here is also<br />

integrating PAT and QbD in the<br />

conceptual design, in accordance<br />

with the regulators’ mindset, i.e. to<br />

bring in the quality aspects directly<br />

into the design process and with the<br />

help of available powerful PAT<br />

methods and tools.<br />

It is our interpretation of PAT<br />

that the HE modeling methodology<br />

can be considered as one of the<br />

useful PAT tools.<br />

Manufacturing aspects on<br />

stem cell production<br />

Scaled-up manufacturing of hESC and<br />

hESC-derived products requires<br />

access to exclusive biological<br />

systems, perfectly controlled and<br />

contamination-free manufacturing<br />

facilities, traceability of raw materials,<br />

xeno-free media, specialised<br />

equipment for handling cell culture, a<br />

variety of analytical instrument and<br />

quality control devices and, most<br />

importantly, very skilled and well<br />

trained staff and operators. The<br />

equipment should preferably be as<br />

automated as possible and the<br />

manufacturing should be performed<br />

in a clean room surrounding to reduce<br />

the risk for contamination.<br />

Most of the manufacturing<br />

equipment is commercially available<br />

such as freezing equipment, robots,<br />

incubators, microscopes, analysers,<br />

autopipets, vessels and other culturing<br />

devices. Consumables, single-use<br />

plastics, reagents and media are<br />

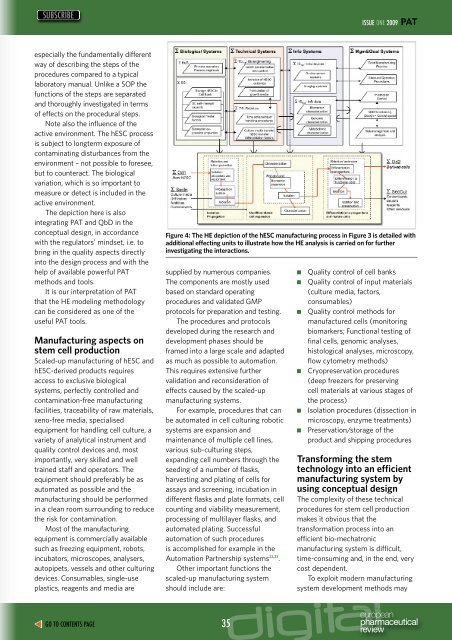

Figure 4: The HE depiction of the hESC manufacturing process in Figure 3 is detailed with<br />

additional effecting units to illustrate how the HE analysis is carried on for further<br />

investigating the interactions.<br />

supplied by numerous companies.<br />

The components are mostly used<br />

based on standard operating<br />

procedures and validated GMP<br />

protocols for preparation and testing.<br />

The procedures and protocols<br />

developed during the research and<br />

development phases should be<br />

framed into a large scale and adapted<br />

as much as possible to automation.<br />

This requires extensive further<br />

validation and reconsideration of<br />

effects caused by the scaled-up<br />

manufacturing systems.<br />

For example, procedures that can<br />

be automated in cell culturing robotic<br />

systems are expansion and<br />

maintenance of multiple cell lines,<br />

various sub-culturing steps,<br />

expanding cell numbers through the<br />

seeding of a number of flasks,<br />

harvesting and plating of cells for<br />

assays and screening, incubation in<br />

different flasks and plate formats, cell<br />

counting and viability measurement,<br />

processing of multilayer flasks, and<br />

automated plating. Successful<br />

automation of such procedures<br />

is accomplished for example in the<br />

Automation Partnership systems 22,23 .<br />

Other important functions the<br />

scaled-up manufacturing system<br />

should include are:<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Quality control of cell banks<br />

Quality control of input materials<br />

(culture media, factors,<br />

consumables)<br />

Quality control methods for<br />

manufactured cells (monitoring<br />

biomarkers; Functional testing of<br />

final cells, genomic analyses,<br />

histological analyses, microscopy,<br />

flow cytometry methods)<br />

Cryopreservation procedures<br />

(deep freezers for preserving<br />

cell materials at various stages of<br />

the process)<br />

Isolation procedures (dissection in<br />

microscopy, enzyme treatments)<br />

Preservation/storage of the<br />

product and shipping procedures<br />

Transforming the stem<br />

technology into an efficient<br />

manufacturing system by<br />

using conceptual design<br />

The complexity of these technical<br />

procedures for stem cell production<br />

makes it obvious that the<br />

transformation process into an<br />

efficient bio-mechatronic<br />

manufacturing system is difficult,<br />

<strong>time</strong>-consuming and, in the end, very<br />

cost dependent.<br />

To exploit modern manufacturing<br />

system development methods may<br />

GO TO CONTENTS PAGE 35