Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PAT ISSUE 2009<br />

appear as an inevitable stage for<br />

reaching a competitive manufacture.<br />

However, the design theory is<br />

originally shaped and predominantly<br />

used for “cars and freezers”. The<br />

Hubka-Eder model has, to our<br />

knowledge, never before been<br />

adapted for and applied to sensitive<br />

biological systems in a mechatronic<br />

environment.<br />

It is most likely that a<br />

manufacturing facility for hESC<br />

products needs to be flexible in terms<br />

of different final products, i.e. hESCderived<br />

cell types or undifferentiated<br />

hESC materials of a particular cell line.<br />

The customers will no doubt have<br />

varying demands depending on the<br />

purpose of the cells (for clinical-grade<br />

use, for drug testing etc). The quantity<br />

of the cells required will vary<br />

considerably over <strong>time</strong>. The<br />

distribution/shipping conditions will be<br />

more or less demanding. A hESC<br />

manufacturer may, of course, specialise<br />

on certain customers and cell types.<br />

However, from a manufacturing<br />

engineering perspective, an interesting<br />

question is how to make a robust<br />

flexible manufacturing system that can<br />

cope with the varying demands in order<br />

to be as competitive as possible on the<br />

market. The demands for robustness<br />

imply that robots should be used<br />

instead of human operators whenever<br />

possible. The variability and risk for<br />

mistakes due to monotonous and<br />

repetitive work are much smaller for<br />

robotic systems than for human<br />

operators.<br />

In Figure 4 (see page 35) the<br />

stem cell production stages are<br />

transformed into the Hubka-Eder<br />

design model on a more detailed<br />

level. The shown example concerns a<br />

manufacture of a differentiated cell<br />

type: from the isolation of embryonic<br />

cells of blastocytes, their<br />

propagations on feeder cells,<br />

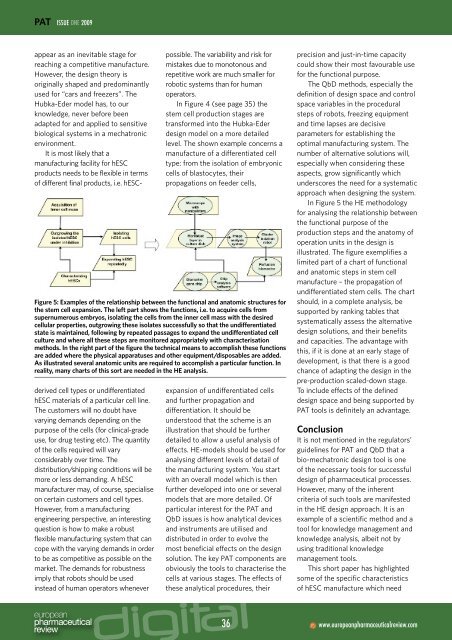

Figure 5: Examples of the relationship between the functional and anatomic structures for<br />

the stem cell expansion. The left part shows the functions, i.e. to acquire cells from<br />

supernumerous embryos, isolating the cells from the inner cell mass with the desired<br />

cellular properties, outgrowing these isolates successfully so that the undifferentiated<br />

state is maintained, following by repeated passages to expand the undifferentiated cell<br />

culture and where all these steps are monitored appropriately with characterisation<br />

methods. In the right part of the figure the technical means to accomplish these functions<br />

are added where the physical apparatuses and other equipment/disposables are added.<br />

As illustrated several anatomic units are required to accomplish a particular function. In<br />

reality, many charts of this sort are needed in the HE analysis.<br />

expansion of undifferentiated cells<br />

and further propagation and<br />

differentiation. It should be<br />

understood that the scheme is an<br />

illustration that should be further<br />

detailed to allow a useful analysis of<br />

effects. HE-models should be used for<br />

analysing different levels of detail of<br />

the manufacturing system. You start<br />

with an overall model which is then<br />

further developed into one or several<br />

models that are more detailed. Of<br />

particular interest for the PAT and<br />

QbD issues is how analytical devices<br />

and instruments are utilised and<br />

distributed in order to evolve the<br />

most beneficial effects on the design<br />

solution. The key PAT components are<br />

obviously the tools to characterise the<br />

cells at various stages. The effects of<br />

these analytical procedures, their<br />

precision and just-in-<strong>time</strong> capacity<br />

could show their most favourable use<br />

for the functional purpose.<br />

The QbD methods, especially the<br />

definition of design space and control<br />

space variables in the procedural<br />

steps of robots, freezing equipment<br />

and <strong>time</strong> lapses are decisive<br />

parameters for establishing the<br />

optimal manufacturing system. The<br />

number of alternative solutions will,<br />

especially when considering these<br />

aspects, grow significantly which<br />

underscores the need for a systematic<br />

approach when designing the system.<br />

In Figure 5 the HE methodology<br />

for analysing the relationship between<br />

the functional purpose of the<br />

production steps and the anatomy of<br />

operation units in the design is<br />

illustrated. The figure exemplifies a<br />

limited part of a chart of functional<br />

and anatomic steps in stem cell<br />

manufacture – the propagation of<br />

undifferentiated stem cells. The chart<br />

should, in a complete analysis, be<br />

supported by ranking tables that<br />

systematically assess the alternative<br />

design solutions, and their benefits<br />

and capacities. The advantage with<br />

this, if it is done at an early stage of<br />

development, is that there is a good<br />

chance of adapting the design in the<br />

pre-production scaled-down stage.<br />

To include effects of the defined<br />

design space and being supported by<br />

PAT tools is definitely an advantage.<br />

Conclusion<br />

It is not mentioned in the regulators’<br />

guidelines for PAT and QbD that a<br />

bio-mechatronic design tool is one<br />

of the necessary tools for successful<br />

design of pharmaceutical processes.<br />

However, many of the inherent<br />

criteria of such tools are manifested<br />

in the HE design approach. It is an<br />

example of a scientific method and a<br />

tool for knowledge management and<br />

knowledge analysis, albeit not by<br />

using traditional knowledge<br />

management tools.<br />

This short paper has highlighted<br />

some of the specific characteristics<br />

of hESC manufacture which need<br />

36<br />

www.europeanpharmaceuticalreview.com