Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Real time PCR - European Pharmaceutical Review

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SUBSCRIBE<br />

ISSUE<br />

2009 THERMAL ANALYSIS<br />

(a common problem with pressurised<br />

metered dose inhalers (pMDI)).<br />

As has been discussed in the<br />

literature 1 , the processes involved in<br />

particle size reduction during milling<br />

are complex. The mechanical forces<br />

imparted to a crystalline material<br />

during milling result initially in a<br />

reduction in particle size, as the<br />

material fractures along natural fault<br />

lines and crystal defects. Eventually<br />

there comes a point at which the bulk<br />

material can no longer fracture and<br />

maximum particle size reduction has<br />

been achieved. Post this point,<br />

mechanical forces are still being<br />

applied and must be absorbed and<br />

dissipated by the sample; these<br />

processes result initially in production<br />

of surface dislocations and eventually<br />

generation of amorphous regions; so<br />

called process-induced disorder.<br />

As has been well documented<br />

elsewhere 2,3 , the amount of<br />

amorphous material formed in this<br />

way is usually small (of the order of a<br />

few percent w/w); however, the nature<br />

of the force applied (impaction)<br />

means that this amorphous material<br />

must necessarily be located on the<br />

surface of the milled material and,<br />

hence, although the milled material is<br />

predominantly crystalline it behaves<br />

as if it were entirely amorphous.<br />

Newell at al 4 published some inverse<br />

phase gas chromatography (IGC) data<br />

(see Table 1) that convey this point. It<br />

is inevitable that this amorphous<br />

material will crystallise, probably over<br />

a relatively short <strong>time</strong>frame as it is<br />

located on a crystalline substrate that<br />

can act as a seed. Crystallisation of<br />

the surface may have disastrous<br />

consequences for the function of the<br />

product 5 , primarily because the force<br />

of adhesion between drug and carrier<br />

will change, altering the balance of<br />

forces that is so important in<br />

modulating product performance from<br />

batch-to-batch and within one batch<br />

over <strong>time</strong>. As such, it is imperative to<br />

understand the mechanisms and<br />

kinetics of crystallisation, such that its<br />

effects can be ameliorated. Often this<br />

means conditioning (under humidity<br />

or some other suitable plasticising<br />

vapour) the material post micronising<br />

to force crystallisation.<br />

If it is true that particle size<br />

reduction occurs before, and not<br />

concomitantly with, generation of<br />

process induced disorder then it is<br />

apparent that it would be possible to<br />

micronise a sample without<br />

generating any amorphous material.<br />

This would remove the need for<br />

downstream conditioning and ensure<br />

consistent product performance. It is<br />

not possible to optimise milling by<br />

following particle size reduction<br />

alone, since there is no particle sizing<br />

technique that can simultaneously<br />

detect formation of amorphous<br />

content. Returning to the data shown<br />

in Figure 1 (page 28), it is tempting to<br />

set up a process involving four to five<br />

micronising steps, since this seems<br />

to ensure a consistent particle size<br />

distribution; such an approach<br />

does nothing to report the generation<br />

of process induced disorder and<br />

can lead to the batch-to-batch<br />

variability in product performance<br />

noted above.<br />

Here, we show that following the<br />

micronising process with an<br />

additional technique, isothermal<br />

microcalorimetry, affords extra data<br />

that allows optimisation of the<br />

micronising <strong>time</strong>. In addition, the data<br />

allow the hypothesis that particle size<br />

reduction occurs before the<br />

generation of process induced<br />

disorder to be tested.<br />

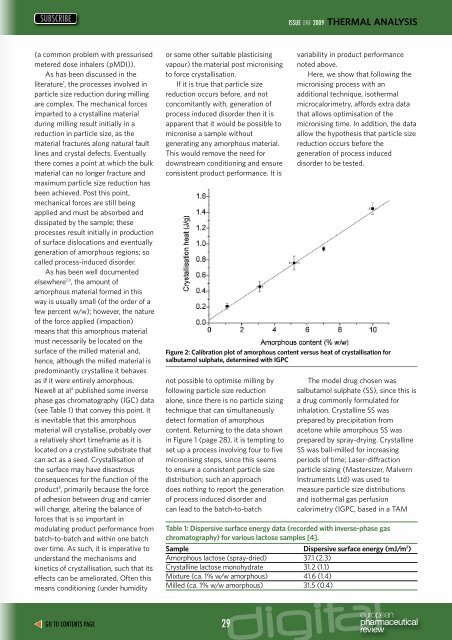

Figure 2: Calibration plot of amorphous content versus heat of crystallisation for<br />

salbutamol sulphate, determined with IGPC<br />

The model drug chosen was<br />

salbutamol sulphate (SS), since this is<br />

a drug commonly formulated for<br />

inhalation. Crystalline SS was<br />

prepared by precipitation from<br />

acetone while amorphous SS was<br />

prepared by spray-drying. Crystalline<br />

SS was ball-milled for increasing<br />

periods of <strong>time</strong>; Laser-diffraction<br />

particle sizing (Mastersizer, Malvern<br />

Instruments Ltd) was used to<br />

measure particle size distributions<br />

and isothermal gas perfusion<br />

calorimetry (IGPC, based in a TAM<br />

Table 1: Dispersive surface energy data (recorded with inverse-phase gas<br />

chromatography) for various lactose samples [4].<br />

Sample Dispersive surface energy (mJ/m 2 )<br />

Amorphous lactose (spray-dried) 37.1 (2.3)<br />

Crystalline lactose monohydrate 31.2 (1.1)<br />

Mixture (ca. 1% w/w amorphous) 41.6 (1.4)<br />

Milled (ca. 1% w/w amorphous) 31.5 (0.4)<br />

GO TO CONTENTS PAGE<br />

29