English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

to 60 ft/hour with the hydraulic orienting tool (HOT)<br />

configuration, allowing for all three wells to be completed<br />

two days ahead of schedule.<br />

KSA UBCTD Project Background<br />

The Ghawar field is by far the largest conventional oil field in<br />

the world, and accounts for more than half of the cumulative<br />

oil production of <strong>Saudi</strong> Arabia. Beginning in the 1980s, deep<br />

drilling through the Jurassic beneath Ghawar field has proved<br />

up large reserves of gas, sometimes with condensate in the<br />

Permian Khuff limestone and pre-Khuff sandstone. Now <strong>Saudi</strong><br />

<strong>Aramco</strong> is developing Khuff and pre-Khuff gas beneath<br />

Ghawar 5 .<br />

In several areas around the world, including the U.A.E. 6, 7<br />

and North America 2, 8 , it was proved that UBCTD reentries<br />

can provide cost-effective access for infill drilling activity.<br />

Testing this technology in the Khuff limestone reservoir was a<br />

logical step towards further opening up those resources. In the<br />

summer of 2008, the first UBCTD pilot project in the<br />

Kingdom of <strong>Saudi</strong> Arabia was undertaken to evaluate the<br />

feasibility of reentering old wellbores using UBCTD to reverse<br />

declining gas production.<br />

Vertical Khuff gas producers, completed with 4½”, 5½” or<br />

7” liners, were reentered and sidetracked using CT. A typical<br />

operational sequence for the current UBCTD project includes<br />

running and setting a whipstock and exiting the liner by<br />

milling a window, sidetracking the well and drilling one lateral<br />

across the Khuff formation, performing open hole sidetracks<br />

and drilling up to three more laterals. All operations are<br />

typically performed underbalanced while the well is<br />

producing. As of October 2009, 11 wells (31 laterals) were<br />

successfully drilled, exposing up to 7,000 ft of open hole per<br />

well and averaging 1,511 ft of lateral length.<br />

After a nine well pilot phase was successfully completed<br />

using personnel and best practices from around the world, a<br />

great emphasis was placed on further improving UBCTD<br />

project economics through improved operational efficiency<br />

and the introduction of new underbalanced CT drilling<br />

techniques and services.<br />

As lessons were learned and office engineering personnel<br />

and crews on location became more experienced, the average<br />

number of operating days on location required to drill 500 ft<br />

of open hole fell from 4.2 to below three days, Fig. 1.<br />

New Technology Introduction to UBCTD Project in KSA<br />

Since its first deployment in the Middle East at the end of<br />

March 2009 to October 2009, a 3” RSM tool has been tested<br />

in six consecutive wells drilling 15,551 ft in 15 runs and<br />

successfully performing five open hole sidetracks. The RSM<br />

has contributed to achieving the following major<br />

improvements in drilling the lateral sections:<br />

• Optimization of the biosteering process together with<br />

the introduction of new rib steered technology helped<br />

maximize reservoir exposure, extending lateral reach<br />

Fig. 1. UBCTD project days/500 ft.<br />

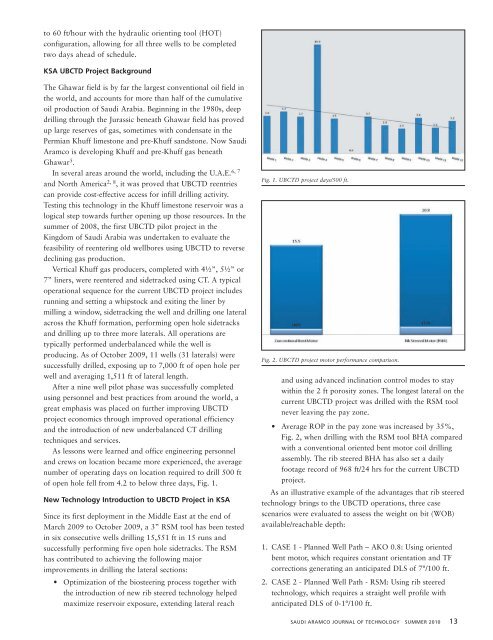

Fig. 2. UBCTD project motor performance comparison.<br />

and using advanced inclination control modes to stay<br />

within the 2 ft porosity zones. The longest lateral on the<br />

current UBCTD project was drilled with the RSM tool<br />

never leaving the pay zone.<br />

• Average ROP in the pay zone was increased by 35%,<br />

Fig. 2, when drilling with the RSM tool BHA compared<br />

with a conventional oriented bent motor coil drilling<br />

assembly. The rib steered BHA has also set a daily<br />

footage record of 968 ft/24 hrs for the current UBCTD<br />

project.<br />

As an illustrative example of the advantages that rib steered<br />

technology brings to the UBCTD operations, three case<br />

scenarios were evaluated to assess the weight on bit (WOB)<br />

available/reachable depth:<br />

1. CASE 1 - Planned Well Path – AKO 0.8: Using oriented<br />

bent motor, which requires constant orientation and TF<br />

corrections generating an anticipated DLS of 7°/100 ft.<br />

2. CASE 2 - Planned Well Path - RSM: Using rib steered<br />

technology, which requires a straight well profile with<br />

anticipated DLS of 0-1°/100 ft.<br />

SAUDI ARAMCO JOURNAL OF TECHNOLOGY SUMMER 2010 13