English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Step Description Fluid Type Average CT Rate (BPM) Time (min.)<br />

1 Preflush (for the first stage only) Gelled Brine 2.5 ~ 3.0 20<br />

2 Erosive Perforating Gel with Sand 2.5 ~ 3.0 12<br />

3 Flush Gel 3 20<br />

4 Bottoms-Up Circulation Gel 2.0 ~ 2.5 72<br />

5 Reduce pumping rate and locate CT in the next desired depth, and repeat steps 2-5.<br />

Table 2. Pumping sequence for one stage of hydrajet perforation<br />

and the formation. Conventional methodologies had achieved<br />

only limited success in the same wells. Figure 3 shows the<br />

results from a field test showing the characteristics of the hole<br />

size and shape created with a hydrajetting tool.<br />

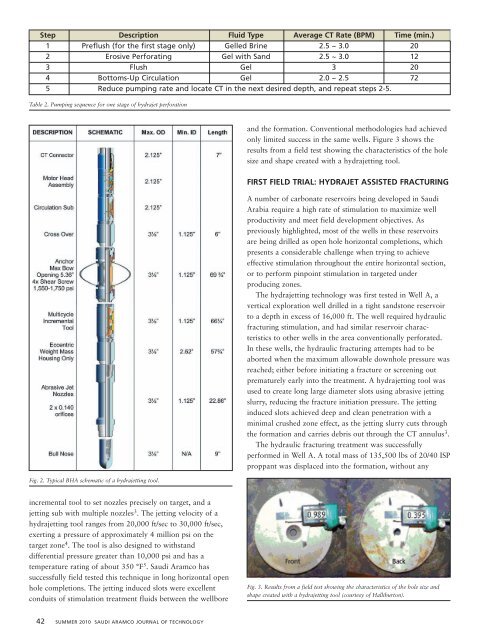

Fig. 2. Typical BHA schematic of a hydrajetting tool.<br />

FIRST FIELD TRIAL: HYDRAJET ASSISTED FRACTURING<br />

A number of carbonate reservoirs being developed in <strong>Saudi</strong><br />

Arabia require a high rate of stimulation to maximize well<br />

productivity and meet field development objectives. As<br />

previously highlighted, most of the wells in these reservoirs<br />

are being drilled as open hole horizontal completions, which<br />

presents a considerable challenge when trying to achieve<br />

effective stimulation throughout the entire horizontal section,<br />

or to perform pinpoint stimulation in targeted under<br />

producing zones.<br />

The hydrajetting technology was first tested in Well A, a<br />

vertical exploration well drilled in a tight sandstone reservoir<br />

to a depth in excess of 16,000 ft. The well required hydraulic<br />

fracturing stimulation, and had similar reservoir characteristics<br />

to other wells in the area conventionally perforated.<br />

In these wells, the hydraulic fracturing attempts had to be<br />

aborted when the maximum allowable downhole pressure was<br />

reached; either before initiating a fracture or screening out<br />

prematurely early into the treatment. A hydrajetting tool was<br />

used to create long large diameter slots using abrasive jetting<br />

slurry, reducing the fracture initiation pressure. The jetting<br />

induced slots achieved deep and clean penetration with a<br />

minimal crushed zone effect, as the jetting slurry cuts through<br />

the formation and carries debris out through the CT annulus 3 .<br />

The hydraulic fracturing treatment was successfully<br />

performed in Well A. A total mass of 135,500 lbs of 20/40 ISP<br />

proppant was displaced into the formation, without any<br />

incremental tool to set nozzles precisely on target, and a<br />

jetting sub with multiple nozzles 3 . The jetting velocity of a<br />

hydrajetting tool ranges from 20,000 ft/sec to 30,000 ft/sec,<br />

exerting a pressure of approximately 4 million psi on the<br />

target zone 4 . The tool is also designed to withstand<br />

differential pressure greater than 10,000 psi and has a<br />

temperature rating of about 350 °F 5 . <strong>Saudi</strong> <strong>Aramco</strong> has<br />

successfully field tested this technique in long horizontal open<br />

hole completions. The jetting induced slots were excellent<br />

conduits of stimulation treatment fluids between the wellbore<br />

Fig. 3. Results from a field test showing the characteristics of the hole size and<br />

shape created with a hydrajetting tool (courtesy of Halliburton).<br />

42 SUMMER 2010 SAUDI ARAMCO JOURNAL OF TECHNOLOGY