English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Application of Hydrajetting Technology<br />

Achieves Significant Productivity Increase in<br />

<strong>Saudi</strong> Arabian Gas Producers<br />

Author: Emad A. Al-Abbad<br />

ABSTRACT<br />

Stimulating gas reservoirs, particularly in horizontal producers,<br />

has presented a considerable challenge to <strong>Saudi</strong> <strong>Aramco</strong>; as<br />

wellbore accessibility is difficult in wells drilled in deeper<br />

formations, with relatively low permeability and high-pressure<br />

and temperature. Therefore, conventional perforating and<br />

stimulation methods have not been as successful as expected<br />

when applied in single and dual-lateral completions.<br />

Alternative techniques, based on hydrajetting technology, have<br />

been recently applied in a number of underperforming<br />

horizontal gas producers with excellent results. The technology<br />

is used to create slots along the horizontal section and then<br />

perform pinpoint acid stimulation treatments. The acid is<br />

displaced in the zones in most need of stimulation, resulting in<br />

significant well productivity and economic enhancement. This<br />

article details the methodology that has been used to apply<br />

hydrajetting technology, and highlights the successful results<br />

and benefits achieved in a number of field trials.<br />

INTRODUCTION<br />

The majority of <strong>Saudi</strong> <strong>Aramco</strong>’s gas producers, targeting<br />

reservoirs in deep and tight formations, are being drilled<br />

horizontally to optimize field development, achieve maximum<br />

reservoir contact and reduce overall cost. Stimulation<br />

treatments are required on a number of these producers,<br />

because their productivity is frequently impaired by either<br />

drilling damage or poor reservoir quality. The conventional<br />

stimulation methods applied early in the field development<br />

history, which included bullheading acid at high-pressure and<br />

rate conditions, and performing coiled tubing (CT) acid<br />

washes, did not improve well productivity at the expected<br />

level 1 . This was not entirely surprising given the difficulty of<br />

placing treatment fluids — in targeted zones in need of<br />

stimulation along lengthy open hole horizontal completions —<br />

in the presence of thief zones, washouts and highly hetero -<br />

geneous reservoir conditions. The problems — associated with<br />

initiating and extending hydraulic fracturing treatments in<br />

vertical wells, drilled in some of the tightest formations and<br />

perforated with conventional methodologies — led to the<br />

search for nonconventional methods, capable of overcoming<br />

the high fracture initiation pressure experienced in these wells.<br />

An innovative hydrajetting tool was developed and field tested<br />

for the first time in a vertical gas producer; with reservoir<br />

characteristics similar to other wells where attempts to<br />

perform proppant hydraulic fracturing treatments resulted in<br />

premature screenouts. The same technique, in combination<br />

with other innovative approaches, was later successfully used<br />

to perform acid stimulation treatments in a number of<br />

underperforming horizontal open hole producers with<br />

excellent results.<br />

HYDRAJETTING OVERVIEW<br />

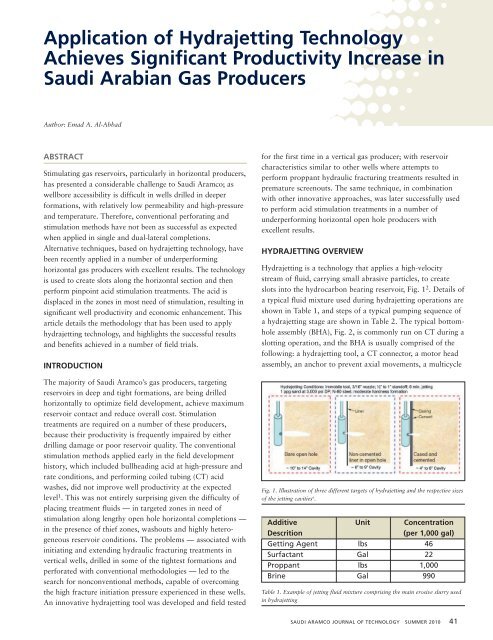

Hydrajetting is a technology that applies a high-velocity<br />

stream of fluid, carrying small abrasive particles, to create<br />

slots into the hydrocarbon bearing reservoir, Fig. 1 2 . Details of<br />

a typical fluid mixture used during hydrajetting operations are<br />

shown in Table 1, and steps of a typical pumping sequence of<br />

a hydrajetting stage are shown in Table 2. The typical bottomhole<br />

assembly (BHA), Fig. 2, is commonly run on CT during a<br />

slotting operation, and the BHA is usually comprised of the<br />

following: a hydrajetting tool, a CT connector, a motor head<br />

assembly, an anchor to prevent axial movements, a multicycle<br />

Fig. 1. Illustration of three different targets of hydrajetting and the respective sizes<br />

of the jetting cavities 6 .<br />

Additive Unit Concentration<br />

Descrition<br />

(per 1,000 gal)<br />

Getting Agent lbs 46<br />

Surfactant Gal 22<br />

Proppant lbs 1,000<br />

Brine Gal 990<br />

Table 1. Example of jetting fluid mixture comprising the main erosive slurry used<br />

in hydrajetting<br />

SAUDI ARAMCO JOURNAL OF TECHNOLOGY SUMMER 2010 41