English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

English Edition (6 MB pdf) - Saudi Aramco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

eciprocated) along the axis of the wellbore, Fig. 6. For<br />

example, the completion string can get stuck in filter cake that<br />

was previously deposited on a permeable zone. Differential<br />

sticking typically occurs when high contact forces caused by<br />

low reservoir pressures, high wellbore pressures, or both, are<br />

exerted over a sufficiently large area of the downhole assembly.<br />

The pipe is held in the cake by a difference in pressures<br />

between the hydrostatic pressure of the mud and the pore<br />

pressure in the permeable zone. A relatively low-differential<br />

pressure (delta p) applied over a large working area can be just<br />

as effective in sticking the pipe as can a high-differential<br />

pressure applied over a small area. The force required to pull<br />

the pipe free can exceed the strength of the pipe.<br />

Mitigation of Differential Sticking with Centralizers<br />

With the knowledge that differential sticking was the most<br />

likely cause of deployment issues for the MSS, the task was to<br />

determine how to overcome these challenges. The most readily<br />

available tool to combat differential sticking is centralization<br />

of the pipe so that it stands off the wellbore. Although it is<br />

widely recognized that centralized pipe is much less prone to<br />

differential sticking, many operations personnel strongly<br />

oppose the use of centralizers because of the increased risk of<br />

mechanical sticking. They cite occasions where they have<br />

attempted to run centralized liners, but could not get them to<br />

the bottom. In these cases, they pulled the liners back to<br />

surface, removed the centralizers, and then were able to force<br />

the liner to TD.<br />

It was immediately realized that the ledge phenomenon that<br />

had been identified early in the deployment of MSS was<br />

possibly the same issue that had caused the problems with<br />

deployment of centralized liners. If so, the gauge/reamer tool<br />

that had been successfully used to address the mechanical<br />

sticking issues for early MSS could also solve the problem<br />

with mechanical sticking when using centralizers.<br />

It was also noted that the centralizers had not been run in<br />

both previous cases where the MSSs had become stuck.<br />

Therefore, the lack of centralization was considered to be the<br />

most significant factor contributing to the MSS becoming stuck.<br />

Other Steps Taken to Reduce Sticking Potential<br />

Several other steps were taken to improve the chances for<br />

successful deployment of MSS assemblies.<br />

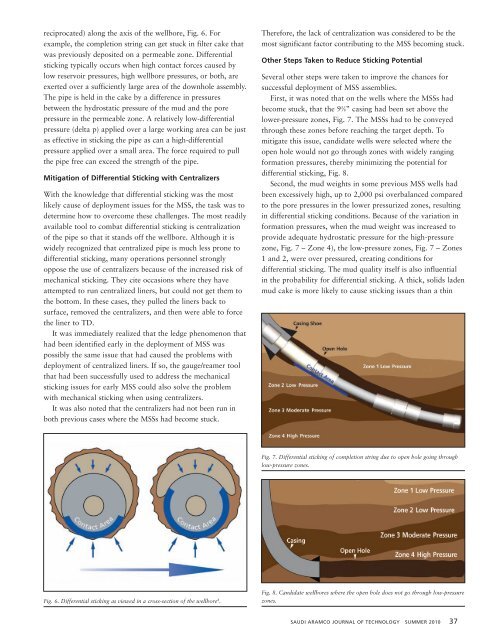

First, it was noted that on the wells where the MSSs had<br />

become stuck, that the 9 5 ⁄8” casing had been set above the<br />

lower-pressure zones, Fig. 7. The MSSs had to be conveyed<br />

through these zones before reaching the target depth. To<br />

mitigate this issue, candidate wells were selected where the<br />

open hole would not go through zones with widely ranging<br />

formation pressures, thereby minimizing the potential for<br />

differential sticking, Fig. 8.<br />

Second, the mud weights in some previous MSS wells had<br />

been excessively high, up to 2,000 psi overbalanced compared<br />

to the pore pressures in the lower pressurized zones, resulting<br />

in differential sticking conditions. Because of the variation in<br />

formation pressures, when the mud weight was increased to<br />

provide adequate hydrostatic pressure for the high-pressure<br />

zone, Fig. 7 – Zone 4), the low-pressure zones, Fig. 7 – Zones<br />

1 and 2, were over pressured, creating conditions for<br />

differential sticking. The mud quality itself is also influential<br />

in the probability for differential sticking. A thick, solids laden<br />

mud cake is more likely to cause sticking issues than a thin<br />

Fig. 7. Differential sticking of completion string due to open hole going through<br />

low-pressure zones.<br />

Fig. 6. Differential sticking as viewed in a cross-section of the wellbore 8 .<br />

Fig. 8. Candidate wellbores where the open hole does not go through low-pressure<br />

zones.<br />

SAUDI ARAMCO JOURNAL OF TECHNOLOGY SUMMER 2010 37