Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

section 4<br />

operation<br />

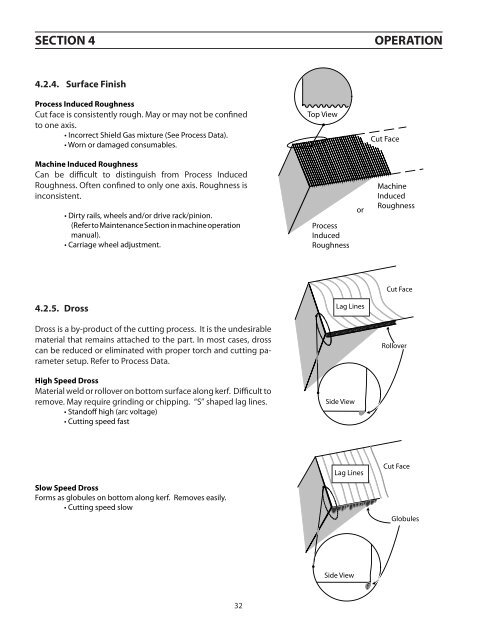

4.2.4. Surface Finish<br />

Process Induced Roughness<br />

Cut face is consistently rough. May or may not be confined<br />

to one axis.<br />

• Incorrect Shield Gas mixture (See Process Data).<br />

• Worn or damaged consumables.<br />

Top View<br />

Cut Face<br />

Machine Induced Roughness<br />

Can be difficult to distinguish from Process Induced<br />

Roughness. Often confined to only one axis. Roughness is<br />

inconsistent.<br />

• Dirty rails, wheels and/or drive rack/pinion.<br />

(Refer to Maintenance Section in machine operation<br />

manual).<br />

• Carriage wheel adjustment.<br />

Process<br />

Induced<br />

Roughness<br />

or<br />

Machine<br />

Induced<br />

Roughness<br />

Cut Face<br />

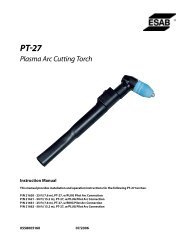

4.2.5. Dross<br />

Lag Lines<br />

Dross is a by-product of the cutting process. It is the undesirable<br />

material that remains attached to the part. In most cases, dross<br />

can be reduced or eliminated with proper torch and cutting parameter<br />

setup. Refer to Process Data.<br />

Rollover<br />

High Speed Dross<br />

Material weld or rollover on bottom surface along kerf. Difficult to<br />

remove. May require grinding or chipping. “S” shaped lag lines.<br />

• Standoff high (arc voltage)<br />

• <strong>Cutting</strong> speed fast<br />

Side View<br />

Slow Speed Dross<br />

Forms as globules on bottom along kerf. Removes easily.<br />

• <strong>Cutting</strong> speed slow<br />

Lag Lines<br />

Cut Face<br />

Globules<br />

Side View<br />

32