Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

section 5<br />

Maintenance<br />

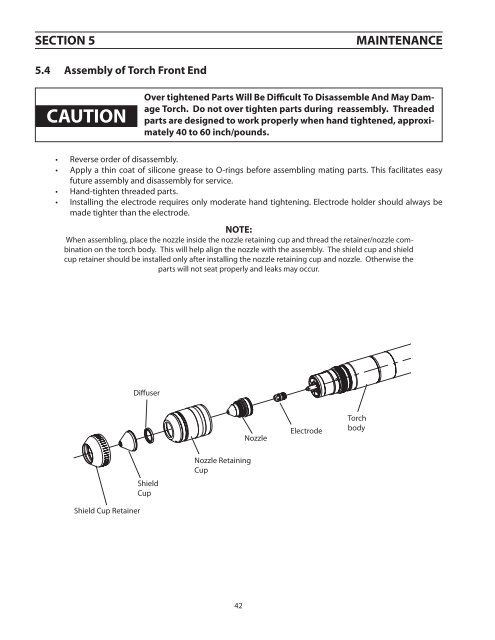

5.4 Assembly of <strong>Torch</strong> Front End<br />

caution<br />

Over tightened Parts Will Be Difficult To Disassemble And May Damage<br />

<strong>Torch</strong>. Do not over tighten parts during reassembly. Threaded<br />

parts are designed to work properly when hand tightened, approximately<br />

40 to 60 inch/pounds.<br />

• Reverse order of disassembly.<br />

• Apply a thin coat of silicone grease to O-rings before assembling mating parts. This facilitates easy<br />

future assembly and disassembly for service.<br />

• Hand-tighten threaded parts.<br />

• Installing the electrode requires only moderate hand tightening. Electrode holder should always be<br />

made tighter than the electrode.<br />

NOTE:<br />

When assembling, place the nozzle inside the nozzle retaining cup and thread the retainer/nozzle combination<br />

on the torch body. This will help align the nozzle with the assembly. The shield cup and shield<br />

cup retainer should be installed only after installing the nozzle retaining cup and nozzle. Otherwise the<br />

parts will not seat properly and leaks may occur.<br />

Diffuser<br />

Nozzle<br />

Electrode<br />

<strong>Torch</strong><br />

body<br />

Shield<br />

Cup<br />

Nozzle Retaining<br />

Cup<br />

Shield Cup Retainer<br />

42