Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

section 5<br />

Maintenance<br />

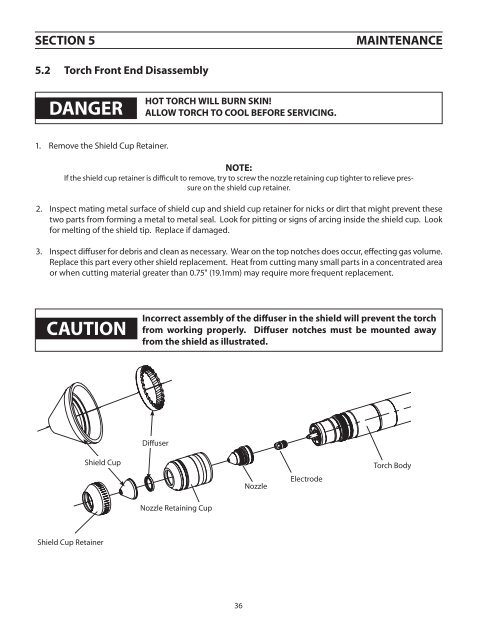

5.2 <strong>Torch</strong> Front End Disassembly<br />

DANGER<br />

Hot <strong>Torch</strong> Will Burn Skin!<br />

Allow torch to cool before servicing.<br />

1. Remove the Shield Cup Retainer.<br />

NOTE:<br />

If the shield cup retainer is difficult to remove, try to screw the nozzle retaining cup tighter to relieve pressure<br />

on the shield cup retainer.<br />

2. Inspect mating metal surface of shield cup and shield cup retainer for nicks or dirt that might prevent these<br />

two parts from forming a metal to metal seal. Look for pitting or signs of arcing inside the shield cup. Look<br />

for melting of the shield tip. Replace if damaged.<br />

3. Inspect diffuser for debris and clean as necessary. Wear on the top notches does occur, effecting gas volume.<br />

Replace this part every other shield replacement. Heat from cutting many small parts in a concentrated area<br />

or when cutting material greater than 0.75" (19.1mm) may require more frequent replacement.<br />

caution<br />

Incorrect assembly of the diffuser in the shield will prevent the torch<br />

from working properly. Diffuser notches must be mounted away<br />

from the shield as illustrated.<br />

Diffuser<br />

Shield Cup<br />

Nozzle<br />

Electrode<br />

<strong>Torch</strong> Body<br />

Nozzle Retaining Cup<br />

Shield Cup Retainer<br />

36