Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

section 5<br />

Maintenance<br />

4. Unscrew nozzle retainer and pull nozzle straight out of torch body. Inspect insulator portion of the nozzle<br />

retainer for cracks or chipping. Replace if damaged.<br />

Inspect nozzle for:<br />

• melting or excessive current transfer.<br />

• gouges from internal arcing.<br />

• nicks or deep scratches on the O-ring seating surfaces .<br />

• O-ring cuts, nicks, or wear.<br />

• Remove hafnium particles (from the nozzle) with steel wool.<br />

Replace if any damage is found.<br />

NOTE:<br />

Discoloration of internal surfaces and small black starting marks are normal and do not effect cutting<br />

performance.<br />

If the holder was tightened sufficiently, the electrode may unscrew without being attached to the electrode<br />

holder. When installing the electrode, use only sufficient force to adequately secure the electrode.<br />

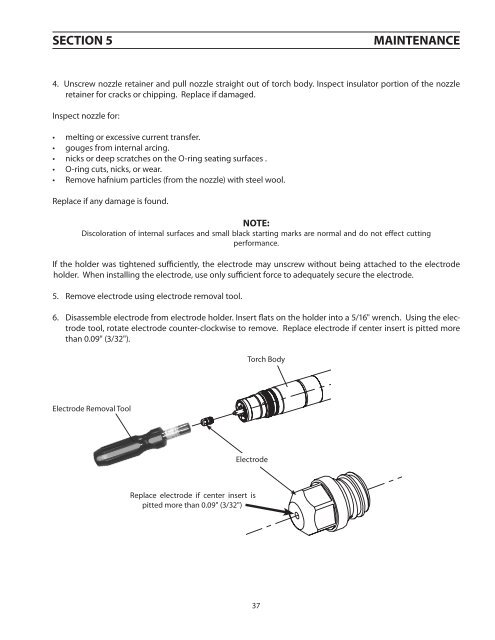

5. Remove electrode using electrode removal tool.<br />

6. Disassemble electrode from electrode holder. Insert flats on the holder into a 5/16" wrench. Using the electrode<br />

tool, rotate electrode counter-clockwise to remove. Replace electrode if center insert is pitted more<br />

than 0.09" (3/32").<br />

<strong>Torch</strong> Body<br />

Electrode Removal Tool<br />

Electrode<br />

Replace electrode if center insert is<br />

pitted more than 0.09" (3/32")<br />

37