BIO, BIOA, ZIO

BIO, BIOA, ZIO

BIO, BIOA, ZIO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

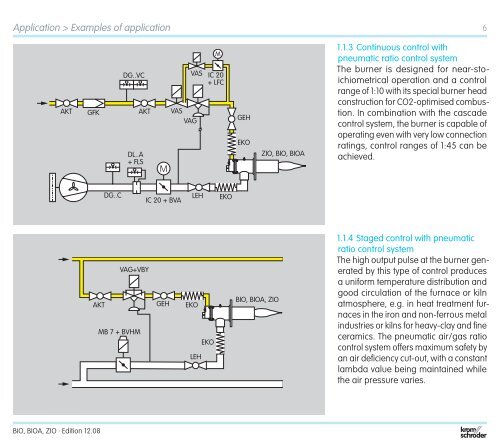

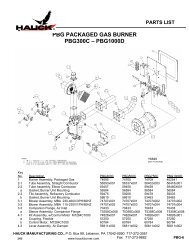

Application > Examples of application<br />

6<br />

DG..VC<br />

AKT GFK AKT<br />

DL..A<br />

+ FLS<br />

M<br />

VAS<br />

VAS<br />

VAG<br />

M<br />

IC 20<br />

+ LFC<br />

GEH<br />

EKO<br />

<strong>ZIO</strong>, <strong>BIO</strong>, <strong>BIO</strong>A<br />

1.1.3 Continuous control with<br />

pneumatic ratio control system<br />

The burner is designed for near-stoichiometrical<br />

operation and a control<br />

range of 1:10 with its special burner head<br />

construction for CO2-optimised combustion.<br />

In combination with the cascade<br />

control system, the burner is capable of<br />

operating even with very low connection<br />

ratings, control ranges of 1:45 can be<br />

achieved.<br />

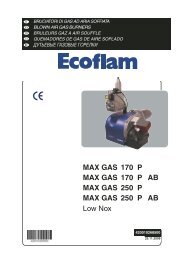

DG..C<br />

IC 20 + BVA<br />

LEH<br />

EKO<br />

AKT<br />

VAG+VBY<br />

MB 7 + BVHM<br />

GEH<br />

EKO<br />

LEH<br />

EKO<br />

<strong>BIO</strong>, <strong>BIO</strong>A, <strong>ZIO</strong><br />

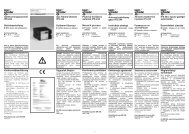

1.1.4 Staged control with pneumatic<br />

ratio control system<br />

The high output pulse at the burner generated<br />

by this type of control produces<br />

a uniform temperature distribution and<br />

good circulation of the furnace or kiln<br />

atmosphere, e.g. in heat treatment furnaces<br />

in the iron and non-ferrous metal<br />

industries or kilns for heavy-clay and fine<br />

ceramics. The pneumatic air/gas ratio<br />

control system offers maximum safety by<br />

an air deficiency cut-out, with a constant<br />

lambda value being maintained while<br />

the air pressure varies.<br />

<strong>BIO</strong>, <strong>BIO</strong>A, <strong>ZIO</strong> · Edition 12.08