OkCBP

OkCBP

OkCBP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Capacity building<br />

As an important element of our approach,<br />

we provide free, online Code of Conduct<br />

training to suppliers, offered in 13 languages.<br />

In 2014, Ericsson also launched a<br />

web-based anti-corruption training for<br />

suppliers to reinforce our zero tolerance<br />

view on corruption and bribery.<br />

Meeting customer expectations<br />

Our own performance as a supplier is a<br />

critical part of our proactive engagement<br />

in responsible sourcing. We participate in<br />

the yearly Joint Audit Cooperation (JAC)<br />

Forum made up of ten of our largest customers,<br />

telecom operators. JAC members<br />

conduct Corporate Responsibility audits of<br />

their suppliers, including Ericsson factories<br />

and suppliers, and share results. Several<br />

Ericsson and supplier sites have been<br />

audited by JAC auditors during the past<br />

few years with satisfactory results.<br />

collaborating with<br />

supplier a win-win<br />

When a supplier is closely aligned with our strong commitment to find<br />

sustainable solutions, collaboration can lead to significant improvements.<br />

That is the case with global logistics provider DB Schenker,<br />

which worked jointly with local Ericsson teams to address the challenge<br />

of transporting products from Ericsson in China to our facilities<br />

in Brazil – all while reducing lead time, costs and carbon impact.<br />

By jointly tackling the problem, Ericsson and DB Schenker arrived<br />

at a sustainable multi-modal solution combining rail with air freight<br />

which reduced CO 2 emissions by 47% per 45ft container and cut lead<br />

time from 45–50 days by sea freight to 23–25 days with the rail-air<br />

combi nation. In addition, intermodal air-rail transports developed by<br />

DB Schenker together with Ericsson for our inbound flows to and<br />

from Europe and China has led to a 56% reduction in CO 2 per 45 ft<br />

container.<br />

Close and ongoing dialogue with the supplier – central to our<br />

Responsible Sourcing approach – was key to ensuring they understood<br />

our requirements and could develop the right solution. In 2014,<br />

Ericsson presented an award to DB Schenker for sustainability excellence,<br />

an example of how working together with a supplier can<br />

achieve positive outcomes with long-term benefits for Ericsson.<br />

Photo: DB Schenker<br />

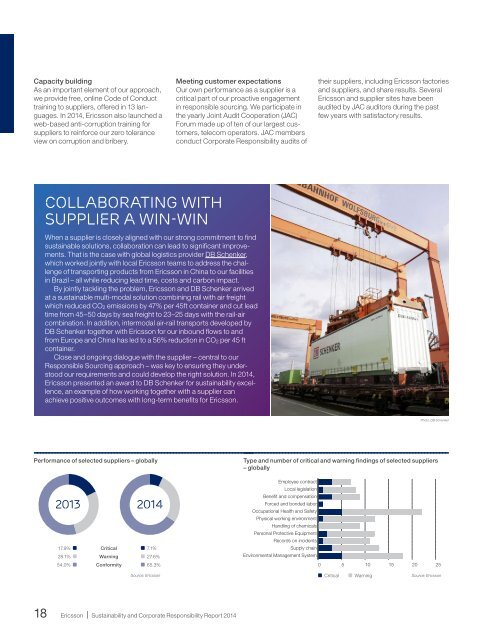

Performance of selected suppliers – globally<br />

2013 2014<br />

17.9% Critical 7.1%<br />

28.1% Warning 27.6%<br />

54.0% Conformity 65.3%<br />

Type and number of critical and warning findings of selected suppliers<br />

– globally<br />

Employee contract<br />

Local legislation<br />

Benefit and compensation<br />

Forced and bonded labor<br />

Occupational Health and Safety<br />

Physical working environment<br />

Handling of chemicals<br />

Personal Protective Equipment<br />

Records on incidents<br />

Supply chain<br />

Environmental Management System<br />

0 5 10 15 20 25<br />

Source: Ericsson<br />

Critical<br />

Warning<br />

Source: Ericsson<br />

18 Ericsson | Sustainability and Corporate Responsibility Report 2014