You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

0<br />

DELTABOOSTER_GB01<br />

Structure<br />

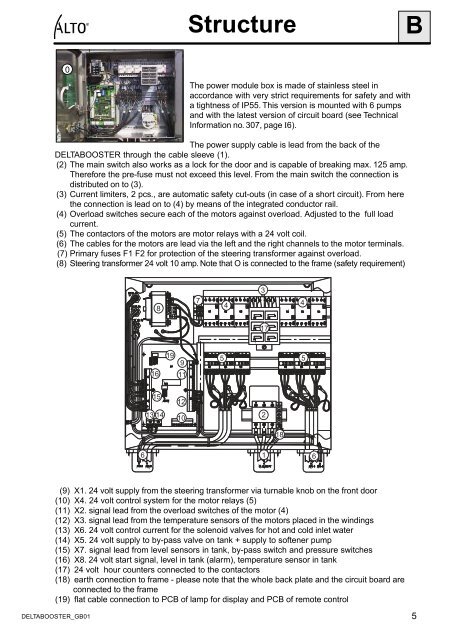

The power module box is made of stainless steel in<br />

accordance with very strict requirements for safety and with<br />

a tightness of IP55. This version is mounted with 6 pumps<br />

and with the latest version of circuit board (see Technical<br />

Information no. 307, page I6).<br />

The power supply cable is lead from the back of the<br />

DELTABOOSTER through the cable sleeve (1).<br />

(2) The main switch also works as a lock for the door and is capable of breaking max. 125 amp.<br />

Therefore the pre-fuse must not exceed this level. From the main switch the connection is<br />

distributed on to (3).<br />

(3) Current limiters, 2 pcs., are automatic safety cut-outs (in case of a short circuit). From here<br />

the connection is lead on to (4) by means of the integrated conductor rail.<br />

(4) Overload switches secure each of the motors against overload. Adjusted to the full load<br />

current.<br />

(5) The contactors of the motors are motor relays with a 24 volt coil.<br />

(6) The cables for the motors are lead via the left and the right channels to the motor terminals.<br />

(7) Primary fuses F1 F2 for protection of the steering transformer against overload.<br />

(8) Steering transformer 24 volt 10 amp. Note that O is connected to the frame (safety requirement)<br />

6<br />

8<br />

16<br />

15<br />

13 14<br />

19<br />

9<br />

11<br />

12<br />

10<br />

7<br />

4<br />

(9) X1. 24 volt supply from the steering transformer via turnable knob on the front door<br />

(10) X4. 24 volt control system for the motor relays (5)<br />

(11) X2. signal lead from the overload switches of the motor (4)<br />

(12) X3. signal lead from the temperature sensors of the motors placed in the windings<br />

(13) X6. 24 volt control current for the solenoid valves for hot and cold inlet water<br />

(14) X5. 24 volt supply to by-pass valve on tank + supply to softener pump<br />

(15) X7. signal lead from level sensors in tank, by-pass switch and pressure switches<br />

(16) X8. 24 volt start signal, level in tank (alarm), temperature sensor in tank<br />

(17) 24 volt hour counters connected to the contactors<br />

(18) earth connection to frame - please note that the whole back plate and the circuit board are<br />

connected to the frame<br />

(19) flat cable connection to PCB of lamp for display and PCB of remote control<br />

3<br />

17<br />

5 5<br />

2<br />

18<br />

4<br />

1 6<br />

B<br />

5