Thermal applicability of two-phase thermosyphons in ... - LEPTEN

Thermal applicability of two-phase thermosyphons in ... - LEPTEN

Thermal applicability of two-phase thermosyphons in ... - LEPTEN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

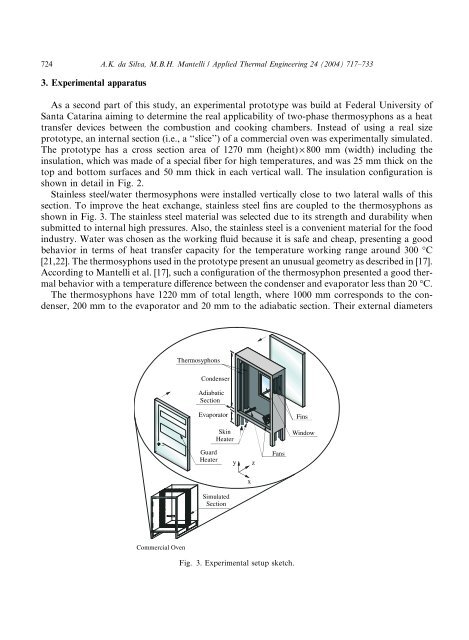

724 A.K. da Silva, M.B.H. Mantelli / Applied <strong>Thermal</strong> Eng<strong>in</strong>eer<strong>in</strong>g 24 (2004) 717–7333. Experimental apparatusAs a second part <strong>of</strong> this study, an experimental prototype was build at Federal University <strong>of</strong>Santa Catar<strong>in</strong>a aim<strong>in</strong>g to determ<strong>in</strong>e the real <strong>applicability</strong> <strong>of</strong> <strong>two</strong>-<strong>phase</strong> <strong>thermosyphons</strong> as a heattransfer devices between the combustion and cook<strong>in</strong>g chambers. Instead <strong>of</strong> us<strong>in</strong>g a real sizeprototype, an <strong>in</strong>ternal section (i.e., a ‘‘slice’’) <strong>of</strong> a commercial oven was experimentally simulated.The prototype has a cross section area <strong>of</strong> 1270 mm (height) · 800 mm (width) <strong>in</strong>clud<strong>in</strong>g the<strong>in</strong>sulation, which was made <strong>of</strong> a special fiber for high temperatures, and was 25 mm thick on thetop and bottom surfaces and 50 mm thick <strong>in</strong> each vertical wall. The <strong>in</strong>sulation configuration isshown <strong>in</strong> detail <strong>in</strong> Fig. 2.Sta<strong>in</strong>less steel/water <strong>thermosyphons</strong> were <strong>in</strong>stalled vertically close to <strong>two</strong> lateral walls <strong>of</strong> thissection. To improve the heat exchange, sta<strong>in</strong>less steel f<strong>in</strong>s are coupled to the <strong>thermosyphons</strong> asshown <strong>in</strong> Fig. 3. The sta<strong>in</strong>less steel material was selected due to its strength and durability whensubmitted to <strong>in</strong>ternal high pressures. Also, the sta<strong>in</strong>less steel is a convenient material for the food<strong>in</strong>dustry. Water was chosen as the work<strong>in</strong>g fluid because it is safe and cheap, present<strong>in</strong>g a goodbehavior <strong>in</strong> terms <strong>of</strong> heat transfer capacity for the temperature work<strong>in</strong>g range around 300 °C[21,22]. The <strong>thermosyphons</strong> used <strong>in</strong> the prototype present an unusual geometry as described <strong>in</strong> [17].Accord<strong>in</strong>g to Mantelli et al. [17], such a configuration <strong>of</strong> the thermosyphon presented a good thermalbehavior with a temperature difference between the condenser and evaporator less than 20 °C.The <strong>thermosyphons</strong> have 1220 mm <strong>of</strong> total length, where 1000 mm corresponds to the condenser,200 mm to the evaporator and 20 mm to the adiabatic section. Their external diametersThermosyphonsCondenser-AdiabaticSectionEvaporatorSk<strong>in</strong>HeaterF<strong>in</strong>sW<strong>in</strong>dowGuardHeateryzFansxSimulatedSectionCommercial OvenFig. 3. Experimental setup sketch.