Face grooving with URMA IntraMax and boring with ... - Horn USA, Inc.

Face grooving with URMA IntraMax and boring with ... - Horn USA, Inc.

Face grooving with URMA IntraMax and boring with ... - Horn USA, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Face</strong> <strong>grooving</strong> <strong>with</strong><strong>URMA</strong> <strong>IntraMax</strong><strong>and</strong><strong>boring</strong> <strong>with</strong><strong>URMA</strong> fine <strong>boring</strong> headBenefits of SynergyNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN1

SUMMARYAdaptor <strong>with</strong> Beta module 40/63Fine <strong>boring</strong> head 05 <strong>IntraMax</strong> 49-88or<strong>IntraMax</strong> 87-207NIn the UNITED STATES call us toll free1 - 888 - 818 HORNN3

ADAPTORS System <strong>URMA</strong>Adaptor <strong>with</strong> Beta module 40/63- Case-hardened <strong>and</strong> ground- Side lock system for quick change of Beta module components- Location pocket for Data chip upon requestPart numberFine <strong>boring</strong>head 05<strong>IntraMax</strong> 49-88<strong>IntraMax</strong> 87-207Beta moduleBD10 40A 40 035 • • -35 16 0.9 kgA SK40BD10 50A 40 060 • • - 60 41 3.0 kg A SK504042BD10 40B 40 035 • • - 35 16 0.9 kg B SK40BD10 50B 40 060 • • - 60 41 3.0 kg B SK50BD10 40A 63 065 - - •65 46 1.5 kgA SK40BD10 50A 63 060 - - • 60 41 3.3 kg A SK506363BD10 40B 63 065 - - • 65 46 1.5 kg B SK40BD10 50B 63 060 - - • 60 41 3.3 kg B SK50Dimensions in mmLglWeightdFormSystemNN4In the UNITED STATES call us toll free1 - 888 - 818 HORN

ADAPTORS System <strong>URMA</strong>Adaptor <strong>with</strong> Beta module 40/63- Case-hardened <strong>and</strong> ground- Side lock system for quick change of Beta module components- Location pocket for Data chip upon requestPart numberFine <strong>boring</strong>head 05<strong>IntraMax</strong> 49-88<strong>IntraMax</strong> 87-207Beta moduleLg ldBI10 40 40 035 • • -35 23 0.7 kgC SK40BI10 50 40 060 • • - 60 45 3.0 kg C SK50BT10 40A 40 028 • • - 28 1 0.9 kg D SK40BT10 50A 40 070 • • - 40 70 32 3.9 kg 42 D SK50BH10 50A 40 065 • • - 65 39 0.7 kg E HSK50BH10 63A 40 065 • • - 65 23 1.1 kg E HSK63BH10 100A 40 080 • • - 80 35 2.3 kg E HSK100BI10 40 63 070 - - •70 58 1.8 kgC SK40BI10 50 63 060 - - • 60 45 3.5 kg C SK50BT10 40A 63 055 - - • 55 28 1.4 kg D SK40BT10 50A 63 080 - - •6380 42 4.3 kg63D SK50BH10 63A 63 080 - - • 80 38 1.5 kg E HSK63BH10 100A 63 080 - - • 80 35 2.8 kg E HSK100WeightFormSystemSpare partsDimensions in mmAdaptorBeta module 40Beta module 63Threaded screwZ004024Z006324NIn the UNITED STATES call us toll free1 - 888 - 818 HORNN5

SUMMARYAdaptor <strong>with</strong> Beta module 40/63Fine <strong>boring</strong> head 05ToolholderType B110ToolholderType B105ToolholderType B105Special solutionsNN6In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING SYSTEM <strong>URMA</strong>FINE BORING HEAD Type05Beta module 40Bore Ø fromNumber of revolutionsAdjustable range0,2 mm20.000 1/min3,0 mm<strong>with</strong> through coolantPart number Beta Module d LgWeightB054020067 40 40 67 1.3 kgDimensions in mmSpare partsFine Boring Head Screw Bolt Threaded ScrewNB054020067 Z004023 Z004021 Z000501In the UNITED STATES call us toll free1 - 888 - 818 HORNN7

BORING SYSTEM <strong>URMA</strong>TOOLHOLDER TypeB105<strong>with</strong> through coolantBore Ø from.008" (0.2 mm)Clamping length 12 mmfor use <strong>with</strong> InsertType105for use <strong>with</strong> <strong>boring</strong> headtype 05Part number d l 1l 2hB105.0016.U1.01 16 39 12 14The double sided clamping surface allows to rotate the toolholder in the <strong>boring</strong> head of 180° . With thisoption it is possible to set the insert behind centre which is necessary for diameters less than Ø .028''.Dimensions in mmNSpare partsToolholder Screw TORX PLUS® WrenchB105.0016.U1.01 6.075T15P T15PQN8In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING SYSTEM <strong>URMA</strong>TOOLHOLDER TypeB105<strong>with</strong> through coolantBore Ø from.197" (5.0 mm)Clamping length 22 mmfor use <strong>with</strong> InsertType105for use <strong>with</strong> <strong>boring</strong> headtype 05Part number d l 1l 2hB105.0016.U1.02 16 49 22 15Toolholders can be used <strong>with</strong> right <strong>and</strong> left h<strong>and</strong> inserts.Dimensions in mmSpare partsToolholder Screw TORX PLUS® WrenchNB105.0016.U1.02 6.075T15P T15PQIn the UNITED STATES call us toll free1 - 888 - 818 HORNN9

BORING SYSTEM <strong>URMA</strong>TOOLHOLDER TypeB110<strong>with</strong> through coolantBore Ø from.236" (6.0 mm)for use <strong>with</strong> InsertType110for use <strong>with</strong> <strong>boring</strong> headtype 05Part number d l 1l 2hB110.0016.U1.02 16 56 29 15Toolholders can be used <strong>with</strong> right <strong>and</strong> left h<strong>and</strong> inserts.Dimensions in mmNSpare partsToolholder Screw TORX PLUS® WrenchB110.0016.U1.02 6.075T15P T15PQN10In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING <strong>and</strong> PROFILING ≥ Ø .008″INSERT Type105Bore Ø from .008″Clamping length .472" (12 mm)for use <strong>with</strong> ToolholderTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a l 2l 5t maxD minr FormMG12TN35TI25TH35R/L105.1802.0.02 .039 .007 .039 .906 .001 .008 .001 B •/•R/L105.1802.0.03 .039 .010 .039 .906 .001 .012 .001 B •/•R/L105.1802.0.05 .039 .016 .079 .906 .002 .020 .002 B •/•R/L105.1803.0.07 .012 .024 .079 .906 .002 .028 .002 A •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN11

BORING <strong>and</strong> PROFILING ≥ Ø .039″INSERT Type105Bore Ø from .039″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.1805.005.0.1.157R/L105.1805.005.1.1 .020 .035 .026 .236 .984 .004 .039 .002R/L105.1805.005.2.1 .315R/L105.1805.0.1.157•/+ •/• •/+R/L105.1805.1.1 .020 .035 .026 .236 .984 .004 .039 .004 •/• •/•R/L105.1805.2.1 .315 •/• •/•R/L105.1813.005.0.15.236 .984R/L105.1813.005.1.15 .051 .055 .043 .354 .984 .006 .059 .002R/L105.1813.005.2.15 .472 1.181R/L105.1813.01.0.15.236 .984•/• •/•R/L105.1813.01.1.15 .051 .055 .043 .354 .984 .006 .059 .004•/• •/•R/L105.1813.01.2.15 .472 1.181 •/• •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNN12In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING <strong>and</strong> PROFILING ≥ Ø .079″INSERT Type105Bore Ø from .079″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.1809.005.0.2.236 .984R/L105.1809.005.1.2 .039 .075 .063 .354 .984R/L105.1809.005.2.2 .472 1.181Dimensions in inchState R or L version.006 .079 .002R/L105.1809.01.0.2.236 .984•/• •/•R/L105.1809.01.1.2 .039 .075 .063 .354 .984 .006 .079 .004•/• •/•R/L105.1809.01.2.2 .472 1.181 •/• •/•R/L105.1809.0.2.236 .984•/+ •/• •/• •/•R/L105.1809.1.2 .039 .075 .063 .354 .984 .006 .079 .006 •/+ •/• •/• •/•R/L105.1809.2.2 .472 1.181 •/+ •/• •/• •/•R/L105.1813.005.0.25.236 .984R/L105.1813.005.1.25 .354 .984.051 .091 .077R/L105.1813.005.2.25 .472 1.181R/L105.1813.005.3.25 .630 1.378.006 .098 .002●/+ = on stock / 6 weeksNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN13

BORING <strong>and</strong> PROFILING ≥ Ø .118″INSERT Type105Bore Ø from .118″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.1813.005.1.3.394 .984R/L105.1813.005.2.3 .051 .102 .091 .591 1.181 .006 .118 .002R/L105.1813.005.3.3 .787 1.378R/L105.1813.01.1.3.394 .984•/• •/•R/L105.1813.01.2.3 .051 .102 .091 .591 1.181 .006 .118 .004•/• •/•R/L105.1813.01.3.3 .787 1.378 •/• •/•R/L105.1813.1.3.394 .984•/• •/• •/• •/•R/L105.1813.2.3 .051 .102 .091 .591 1.181 .006 .118 .008 •/• •/• •/• •/•R/L105.1813.3.3 .787 1.378 •/• •/• •/• •/•R/L105.1819.005.1.4.394 .984R/L105.1819.005.2.4 .075 .146 .114 .591 1.181 .012 .157 .002R/L105.1819.005.3.4 .787 1.378R/L105.1819.1.4.394 .984•/• •/• •/• •/•R/L105.1819.2.4 .075 .146 .114 .591 1.181 .012 .157 .008 •/• •/• •/• •/•R/L105.1819.3.4 .787 1.378 •/• •/• •/• •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNN14In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING <strong>and</strong> PROFILING ≥ Ø .197″INSERT Type105Bore Ø from .197″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.1823.005.1.5R/L105.1823.005.2.5.394.591.9841.181R/L105.1823.005.3.5 .091 .185 .157 .787 1.378R/L105.1823.005.4.5 .984 1.575R/L105.1823.005.5.5 1.181 1.772Dimensions in inchState R or L version.020 .197 .002R/L105.1823.1.5.394 .984•/• •/• •/• •/•R/L105.1823.2.5 .591 1.181 •/• •/• •/• •/•R/L105.1823.3.5 .091 .185 .157 .787 1.378 .020 .197 .008 •/• •/• •/• •/•R/L105.1823.4.5 .984 1.575 •/• •/• •/• •/•R/L105.1823.5.5 1.181 1.772 •/• •/• •/• •/•●/+ = on stock / 6 weeksNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN15

BORING <strong>and</strong> PROFILING ≥ Ø .236″INSERT Type105Bore Ø from .236″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.1833.005.2.6.591 1.181R/L105.1833.005.3.6 .787 1.378.130 .224 .185R/L105.1833.005.4.6 .984 1.575R/L105.1833.005.5.6 1.181 1.772Dimensions in inchState R or L version.020 .236 .002R/L105.1833.2.6.591 1.181•/• •/• •/• •/•R/L105.1833.3.6 .787 1.378 •/• •/• •/• •/•.130 .224 .185.020 .236 .008R/L105.1833.4.6 .984 1.575 •/• •/• •/• •/•R/L105.1833.5.6 1.181 1.772 •/• •/• •/• •/•R/L105.1840.005.3.7.787 1.378R/L105.1840.005.4.7 .157 .252 .205 .984 1.575R/L105.1840.005.5.7 1.181 1.772.020 .268 .002R/L105.1840.3.7.787 1.378•/• •/• •/• •/•R/L105.1840.4.7 .157 .252 .205 .984 1.575 .020 .268 .008 •/• •/• •/• •/•R/L105.1840.5.7 1.181 1.772 •/• •/• •/• •/•●/+ = on stock / 6 weeksNN16In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING <strong>and</strong> PROFILING ≥ Ø .157″INSERT Type105Bore Ø from .157″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> version<strong>with</strong> chip breaker(geometry H)Part number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.1819.1.H4.394 .984+/+R/L105.1819.2.H4 .075 .146 .114 .591 1.181 .012 .157 .008+/+R/L105.1819.3.H4 .787 1.378 +/+R/L105.1823.1.H5.394 .984+/+R/L105.1823.2.H5 .591 1.181 +/+R/L105.1823.3.H5 .091 .185 .157 .787 1.378 .020 .197 .008+/+R/L105.1823.4.H5 .984 1.575 +/+R/L105.1823.5.H5 1.181 1.772 +/+R/L105.1833.2.H6.591 1.181+/+R/L105.1833.3.H6 .787 1.378 +/+.130 .224 .185.020 .236 .008R/L105.1833.4.H6 .984 1.575 +/+R/L105.1833.5.H6 1.181 1.772 +/+R/L105.1840.3.H7.787 1.378+/+R/L105.1840.4.H7 .157 .252 .205 .984 1.575 .020 .268 .008+/+R/L105.1840.5.H7 1.181 1.772 +/+Dimensions in inchState R or L version●/+ = on stock / 6 weeksNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN17

BORING <strong>and</strong> PROFILING ≥ Ø .157″INSERT Type105Bore Ø from .157″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.4719.1.4.394 .984 .024•/•R/L105.4719.3.4.075 .146 .114.787 1.378 .012.157 .006•/• •/• •/•R/L105.4723.2.5.591 1.181 .031•/•R/L105.4723.4.5.091 .185 .146.984 1.575 .020.197 .006•/• •/• •/•R/L105.4733.3.6.787 1.378•/•R/L105.4733.5.6.130 .224 .1461.181 1.772.071 .236 .006•/• +/ •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNN18In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING <strong>and</strong> PROFILING ≥ Ø .118″INSERT Type105Bore Ø from .118″Clamping length .472" (12 mm)for use <strong>with</strong> CartridgeTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minrMG12TN35TI25TH35R/L105.9013.01.1.3.394 .984.004 •/+R/L105.9013.01.2.3 .591 1.181 .004 +/+.051 .102 .091.006 .118R/L105.9013.1.3 .394 .984 .008 •/•R/L105.9013.2.3 .591 1.181 .008 •/•R/L105.9019.01.1.4.394 .984.004 •/+R/L105.9019.01.2.4 .591 1.181 .004 +/+R/L105.9019.01.3.4 .075 .146 .114 .787 1.378 .012 .157 .004 +/+R/L105.9019.1.4 .394 .984 .008 •/•R/L105.9019.2.4 .591 1.181 .008 •/•R/L105.9023.01.1.5.394 .984.004 •/+R/L105.9023.01.2.5 .591 1.181 .004 •/+R/L105.9023.01.3.5 .787 1.378 .004 +/+R/L105.9023.01.4.5 .091 .185 .157 .984 1.575 .020 .197 .004R/L105.9023.1.5 .394 .984 .008 •/• •/R/L105.9023.2.5 .591 1.181 .008 •/•R/L105.9023.3.5 .787 1.378 .008 •/•Dimensions in inchState R or L version●/+ = on stock / 6 weeksNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN19

BORING <strong>and</strong> PROFILINGINSERT Type105<strong>with</strong> extended clamping shankBore Ø from .197″Clamping length .866" (22 mm)for use <strong>with</strong> ToolholderTypeB105BKTR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minr αMG12TN35TI25TF45TH35R/L105.1823.4.5.2.984 1.969•/• •/•R/L105.1823.5.5.2.091 .185 .1651.181 2.165.012 .197 .004 20°•/• •/•R/L105.1833.4.6.2.984 1.969•/• •/•R/L105.1833.5.6.2.130 .224 .1931.181 2.165.012 .236 .004 20°•/• •/•R/L105.1840.4.7.2.984 1.969•/• •/•R/L105.1840.5.7.2 .157 .252 .213 1.181 2.165 .012 .268 .004 20°•/• •/•R/L105.1840.7.7.2 1.575 2.559 •/R/L105.4733.5.6.2 .130 .224 .146 1.181 2.165 .071 .236 .004 47° •/• •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNN20In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING <strong>and</strong> PROFILINGINSERT Type110Bore Ø from .236″Clamping length 26 mmfor use <strong>with</strong> ToolholderTypeB110R = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number f a d l 2l 5t maxD minr αMG12TN35TI25TH35R/L110.1829.7.61.575 2.756•/• •/•R/L110.1829.9.6.114 .224 .1891.969 3.150.020 .236 .008 20°•/• •/•R/L110.1829.9.8 .157 .291 .236 1.969 3.150 .020 .315 .008 20° •/• •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN21

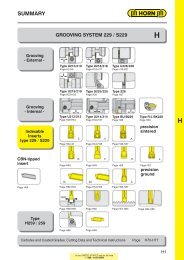

SUMMARYAdaptor <strong>with</strong> Beta module 40/63Basic holder<strong>IntraMax</strong> 49-88or<strong>IntraMax</strong> 87-207Intermediate adaptors<strong>IntraMax</strong> 49-88or<strong>IntraMax</strong> 87-207Diameter extenderNBalanceweightCartridgeType BKT105CartridgeType BKT110CartridgeType BKT105Special solutionsN22In the UNITED STATES call us toll free1 - 888 - 818 HORN

FACE GROOVING SYSTEM <strong>URMA</strong>BASIC HOLDER <strong>URMA</strong> Type<strong>IntraMax</strong> System 49-88- direct mounting for cartridge type BKT105.U90K.01- for balance weight type 020.U00K.040- for diameter extender type 22 03...Part number d LgWeight Diameter Range SystemC11410305252 1.2 kgCAT40D114103052 52 1.2 kg SK40/AH114303052 46 52 1.2 kg 5 - 18SK40/BHSKA116303 60 1.3 kg HSKA-63T114103052 52 1.3 kg MAS-BT40Dimensions in mmSpare partsBasic Holder Urma Screw Washer Cylindrical PinN... C002212 K000201 C001208In the UNITED STATES call us toll free1 - 888 - 818 HORNN23

FACE GROOVINGIntermediate adaptors <strong>URMA</strong><strong>IntraMax</strong> 49-88- direct mounting for cartridge type BKT105.U90K.01- for balance weight type 020.U00K.040- for diameter extender type 22 03...- coupling Beta modulePart number Beta module d L gWeight Diameter rangeB21 40 46 036 40 46 36 0.5 kg 5 - 18Dimensions in mmDiameter extender <strong>URMA</strong><strong>IntraMax</strong> 49-88- Direct mounting for cartridge type BKT105.U90K.01Part number d L gWeight Diameter range22 03 06 012 59 12 0.2 kg 18 - 3122 03 07 012 72 12 0.3 kg 31 - 45Dimensions in mmNSpare partsScrew Washer Screw Key Screw Cylindrical pin BoltC002212 K000201 Z004023 Z004025 C002258 C001208 Z004021N24In the UNITED STATES call us toll free1 - 888 - 818 HORN

FACE GROOVING SYSTEM <strong>URMA</strong>CARTRIDGE TypeBKTfor <strong>URMA</strong> <strong>IntraMax</strong> System 49-88from outer groove ØDepth of groove up to5,0 mm6,0 mmClamping length 12 mmfor use <strong>with</strong> InsertType105Part number l 1h 1b l 2BKT105.U90K.01 24.5 35 28.5 72 Cartridges are suitable from D amin= 2x (6 mm + f Insert)Dimensions in mmSpare partsCartridge Screw TORX PLUS® WrenchNBKT105.U90K.01 6.075T15P T15PQIn the UNITED STATES call us toll free1 - 888 - 818 HORNN25

FACE GROOVING SYSTEM <strong>URMA</strong>BALANCING WEIGHT Type020for <strong>URMA</strong> <strong>IntraMax</strong> System 49-88Part number l 1l 2h 1h 2h 3b020.U00K.2040 24.5 7 35 13 31 22Dimensions in mmNSpare partsBalancing WeightScrew020.U00K.2040 6.075T15N26In the UNITED STATES call us toll free1 - 888 - 818 HORN

FACE GROOVING SYSTEM <strong>URMA</strong>BASIC HOLDER <strong>URMA</strong> Type<strong>IntraMax</strong> SYSTEM 87-207- direct mounting for cartridge type BKT105.U17G.02 <strong>and</strong> BKT105.U90G.01- for balance weight type B21 40 036- for diameter extender type 22 01...Part number d LgWeight Diameter Range SystemC114101054 80 54 1,5 kgCAT40D114101054 80 54 1.4 kg SK40/AH114301054 80 54 1.4 kg 31-61SK40 / BHSKA116301 80 60 1.4 kg HSKA-63T114101054 80 54 1.5 kg MAS-BT40Dimensions in mmSpare partsBasic Holder Urma Screw Screw WasherN... Z002120 C002202 K000220In the UNITED STATES call us toll free1 - 888 - 818 HORNN27

FACE GROOVINGIntermediate adaptors <strong>URMA</strong><strong>IntraMax</strong> 87-207- Direct mounting for cartridge type BKT105.U90G.01<strong>and</strong> BKT110.U17G.02- for balance weight type 230110036- for diameter extender type 22 01...- coupling Beta modulePart number BETA MODULE d L gWeight Diameter rangeB21 63 80 042 63 80 42 0.8 kg 31 - 61Dimensions in mmDiameter extender <strong>URMA</strong><strong>IntraMax</strong> 87-207- Direct mounting for cartridge type BKT105.U90G.01<strong>and</strong> BKT110.U17G.02Part number d L gWeight Diameter range22 01 11 018 110 18 0.8 kg 61 - 9122 01 14 018 140 18 1.0 kg 91 - 12222 01 17 018 170 18 1.2 kg 122 - 15222 01 20 023 200 23 1,6 kg 152 - 182Dimensions in mmSpare partsNType Screw Washer Screw Key Screw Screw Cylindrical pin BoltB21...- Z006321C002202 K000220 Z006023 Z006025 C002205 Z00212022 01... CC001208 -N28In the UNITED STATES call us toll free1 - 888 - 818 HORN

FACE GROOVING SYSTEM <strong>URMA</strong>CARTRIDGE TypeBKTfor <strong>URMA</strong> <strong>IntraMax</strong> System 87-207from outer groove ØDepth of groove up to31,0 mm6,0 mmClamping length 12 mmfor use <strong>with</strong> InsertType105Part number l 1h 1b l 2BKT105.U90G.01 36.4 49 39.5 24.4Dimensions in mmSpare partsCartridge Screw TORX PLUS® WrenchNBKT105.U90G.01 6.075T15P T15PQIn the UNITED STATES call us toll free1 - 888 - 818 HORNN29

FACE GROOVING SYSTEM <strong>URMA</strong>CARTRIDGE TypeBKTfor <strong>URMA</strong> <strong>IntraMax</strong> System 87-207from outer groove ØDepth of groove up to31.0 mm30.0 mmfor use <strong>with</strong> InsertTypeA110Part number l 1h 1b l 2BKT110.U17G.02 41 49 39.5 262 Cartridges are suitable from D amin= 2x (13.5 mm + f Insert)Dimensions in mmNSpare partsCartridge Screw Adjust screw axial TORX PLUS® WrenchBKT110.U17G.02 6.075T15P 030.0006.0488 T15PQN30In the UNITED STATES call us toll free1 - 888 - 818 HORN

FACE GROOVING SYSTEM <strong>URMA</strong>BALANCING WEIGHT Type23for <strong>URMA</strong> <strong>IntraMax</strong> System 87-207Part number Weight l 1l 2h 1h 2h 3b230110036 0.3 kg 36.4 12.5 49 34.8 49 39.5Spare partsBalancing Weight Screw WasherN230110036 C002202 K000220In the UNITED STATES call us toll free1 - 888 - 818 HORNN31

FACE GROOVINGINSERT Type105from outer groove ØDepth of grooveWidth of groove up to.197″.197″.079″for use <strong>with</strong> ToolholderTypeB105BKT105H105HC105VDIR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number w r f l 2l 5t max aD a minMG12TN35TI25TH35R/L105.0510.1.8 .039.079•/+ •/•R/L105.0515.1.8 .059 .002 .079 .394 .984 .118 .197 •/+ •/•R/L105.0520.1.8 .079 .197 •/+ •/•R/L105.0510.2.8 .039.079+/+ •/•R/L105.0515.2.8 .059 .002 .079 .591 1.378 .118 .197 +/+ •/•R/L105.0520.2.8 .079 .197 •/• •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNN32In the UNITED STATES call us toll free1 - 888 - 818 HORN

FACE GROOVINGINSERT Type105from outer groove ØDepth of grooveWidth of groove up to.236″.197″.079″for use <strong>with</strong> ToolholderTypeB105BKT105H105HC105VDIR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number w r f l 2l 5t max aD a minMG12TN35TI25TH35R/L105.0610.1.8 .039.079•/• •/•R/L105.0615.1.8 .059 .002 .079 .394 .984 .118 .236 +/+ •/•R/L105.0620.1.8 .079 .197 •/+ •/•R/L105.0610.2.8 .039.079+/+ +/•R/L105.0615.2.8 .059 .002 .079 .591 1.378 .118 .236 +/ •/+R/L105.0620.2.8 .079 .197 +/+ •/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN33

FACE GROOVINGINSERT Type105from outer groove ØDepth of grooveWidth of groove up to.315″.236″.118″for use <strong>with</strong> ToolholderTypeB105BKT105H105HC105VDIR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number w r f l 2l 5t max aD a minMG12TN35TI25TH35R/L105.0810.1.8 .039.079•/•R/L105.0815.1.8 .059 .118 •/•R/L105.0820.1.8 .079 .006 .079 .394 .984 .157 .315•/•R/L105.0825.1.8 .098 .197 •/•R/L105.0830.1.8 .118 .236 •/•R/L105.0810.2.8 .039.079•/•R/L105.0815.2.8 .059 .118 •/•R/L105.0820.2.8 .079 .006 .079 .591 1.378 .157 .315•/•R/L105.0825.2.8 .098 .197 •/•R/L105.0830.2.8 .118 .236 •/•Dimensions in inchState R or L version●/+ = on stock / 6 weeksNN34In the UNITED STATES call us toll free1 - 888 - 818 HORN

FACE GROOVINGINSERT Type105from outer groove ØDepth of grooveWidth of groove up to.315″.236″.118″for use <strong>with</strong> ToolholderTypeB105BKT105H105HC105VDIR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number w r f l 2l 5t max aD a minMG12TN35TI25TH35R/L105.0810.1.9 .039.079•/•R/L105.0815.1.9 .059 .118 •/•R/L105.0820.1.9 .079 .006 .016 .394 .984 .157 .315•/•R/L105.0825.1.9 .098 .197 •/•R/L105.0830.1.9 .118 .236 •/•Dimensions in inchState R or L version●/+ = on stock / 6 weeksNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN35

FACE GROOVINGINSERT Type105from outer groove ØDepth of grooveWidth of groove up to.315″.236″.118″for use <strong>with</strong> ToolholderTypeB105BKT105H105HC105VDIR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionFull radiusPart number w r f l 2l 5t max aD a minMG12TN35TI25TH35R/L105.8V10.1.8 .039 .020.079•/•R/L105.8V16.1.8 .063 .031 .118 •/•R/L105.8V20.1.8 .079 .039 .079 .394 .984 .157 .315•/•R/L105.8V25.1.8 .098 .049 .197 •/•R/L105.8V30.1.8 .118 .059 .236 •/•R/L105.8V10.2.8 .039 .020.079•/•R/L105.8V16.2.8 .063 .031 .118 •/•R/L105.8V20.2.8 .079 .039 .079 .591 1.378 .157 .315•/•R/L105.8V25.2.8 .098 .049 .197 •/+R/L105.8V30.2.8 .118 .059 .236 •/•Dimensions in inchState R or L version●/+ = on stock / 6 weeksNN36In the UNITED STATES call us toll free1 - 888 - 818 HORN

CHAMFERINGINSERT Type105Angle of chamferWidth of chamfer up to45°/ 60°.157″for use <strong>with</strong> ToolholderTypeB105BKT105H105HC105VDIR = right h<strong>and</strong> version shownL = left h<strong>and</strong> versionPart number r α f l 5t max aD minMG12TN35TI25TF45TH35R/L105.0045.0.1.008 .787•/• /•R/L105.0045.1.1.008 45°.020 .984.138 .039•/•R/L105.0060.0.1.787/•R/L105.0060.1.1.008 60° .020.984.157 .039•/•Dimensions in inch●/+ = on stock / 6 weeksState R or L versionNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN37

FACE GROOVINGINSERT TypeA110from outer groove ØDepth of grooveWidth of groove.787″1.181″.118″for use <strong>with</strong> ToolholderTypeB110R = right h<strong>and</strong> version shownPart number w r f l 5t max aD a minMG12TN35TI25TH35RA110.2030.3.01.969 .787 .787 • • •RA110.2030.5.0 2.362 1.181 .787 • • •.118 .008 .059RA110.5030.3.0 1.969 .787 1.969 •RA110.5030.5.0 2.362 1.181 1.969 •Dimensions in inch<strong>Face</strong> <strong>grooving</strong> <strong>with</strong> full width of the full depth only possible between D amin.787'' - 1.969''.●/+ = on stock / 6 weeksNN38In the UNITED STATES call us toll free1 - 888 - 818 HORN

BALANCING CHARTNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN39

BALANCING CHARTFor Urma fine <strong>boring</strong> head, balanced B05 40 20 067ABalancing the fine <strong>boring</strong> head:1. Loosening the locking screw A2. Align the two scales to set the bore diameter3. Re-tighten the locking screwExample:Insert R105.1823.4.5.2Toolholder B105.0016.U1.01Bore Ø 9 mmPart numberBoreØBore Ø5 6 7 8 9 10R105.1823.4.5.2 5 - 10 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5Dimensions in mmChip areaBore Ø 0.2 - 1.0 mmInsert type left h<strong>and</strong>For this bore range, it's necessary to turn the toolholderB105... by 180°. With this option, it is possible to set theinsert behind the center line which is necessary for Ø lessthan 1.0 mm.Bore Ø > 1.0 mmInsert type right h<strong>and</strong>NChip areaN40In the UNITED STATES call us toll free1 - 888 - 818 HORN

BALANCING CHART Boring ≥ 0.2 mmfor TOOLHOLDER TypeB105.0016.U1.01Part numberBoreØBore Ø0.2/0.5/0.7 1 1.3/2/2.5 3 4L105.1802.0.02*L105.1802.0.03*0.2-1.0 (15-20) 17.0 (15-20) 16.3 - - -L105.1802.0.05* 0.5-1.3 (10-15) 12.0 (10-15) 11.5 (20-25) 21.0 - -L105.1803.0.07* 0.7-1.0 (10-15) 10.3 (10-15) 10.0 -R105.1805.005.0.1R105.1805.005.1.1 1.0-3.0 - (10-15) 10.0 (10-15) 11 (10-15) 12 -R105.1805.005.2.1R105.1805.0.1R105.1805.0.1 1.0-3.0 - (10-15) 10.0 (10-15) 11 (10-15) 12 -R105.1805.0.1R105.1813.005.0.15 (10-15) 10.5 (10-15) 10.5R105.1813.005.1.15 2.5-4.0 - - (10-15) 9.9 (10-15) 10.5 -R105.1813.005.2.15 (10-15) 10.3 -R105.1813.01.0.15 (10-15) 10.5 (10-15) 10.5R105.1813.01.1.15 2.5-4.0 - - (10-15) 9.9 (10-15) 10.5 -R105.1813.01.2.15 (10-15) 10.3 -*It's necessary to turn the toolholder B105.0016.U1.01 by 180°. With this option,it is possible to set the insert behind the center line which is necessary for Ø lessthan 1.0 mm.Dimensions in mmNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN41

BALANCING CHART Boring ≥ 2.0 mmfor TOOLHOLDER TypeB105.0016.U1.01Part numberBoreØBore Ø2 3 4 5 6 7R105.1809.005.0.2R105.1809.005.1.2 2-7 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5R105.1809.005.2.2R105.1809.1.0.2R105.1809.1.1.2 2-7 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5R105.1809.1.2.2R105.1809.005.0.2R105.1809.005.1.2 2-7 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5R105.1809.005.2.2R105.1809.0.2R105.1809.1.2 2-7 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5 (10-15) 10.5R105.1809.2.2R105.1813.005.0.25(10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (10-15) 14.5R105.1813.005.1.25 (10-15) 11.5 (10-15) 13.5 (10-15) 13.5 (10-15) 14.53-8 - (10-15) 10.5R105.1813.005.2.25 (10-15) 11.4 (10-15) 13.4 (10-15) 13.4 (10-15) 14.4R105.1813.005.3.25 (10-15) 11.4 (10-15) 13.4 (10-15) 13.4 (10-15) 14.4Dimensions in mmNN42In the UNITED STATES call us toll free1 - 888 - 818 HORN

BALANCING CHART Boring ≥ 3.0 mmfor TOOLHOLDER TypeB105.0016.U1.01Part numberBoreØBore Ø3 4 5 6 7 8 9R105.1813.005.1.3 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (10-15) 14.5 (15-20) 19.9R105.1813.005.2.3 3-8 (10-15) 10.5 (10-15) 11.5 (10-15) 13.5 (10-15) 13.5 (10-15) 14.5 (15-20) 19.9 -R105.1813.005.3.3 (10-15) 11.4 (10-15) 13.4 (10-15) 13.4 (10-15) 14.4 (15-20) 19.8R105.1813.1.1.3 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (10-15) 14.5 (15-20) 19.9R105.1813.1.2.3 3-8 (10-15) 10.5 (10-15) 11.5 (10-15) 13.5 (10-15) 13.5 (10-15) 14.5 (15-20) 19.9 -R105.1813.1.3.3 (10-15) 11.4 (10-15) 13.4 (10-15) 13.4 (10-15) 14.4 (15-20) 19.8R105.1813.1.3 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (10-15) 14.5 (15-20) 19.9R105.1813.2.3 3-8 (10-15) 10.5 (10-15) 11.5 (10-15) 13.5 (10-15) 13.5 (10-15) 14.5 (15-20) 19.9 -R105.1813.3.3 (10-15) 11.4 (10-15) 13.4 (10-15) 13.4 (10-15) 14.4 (15-20) 19.8R105.1809.005.1.4 (10-15) 10.3 (10-15) 11.3 (10-15) 12.3 (10-15) 13.3 (10-15) 14.3 (15-20) 19.7R105.1809.005.2.4 4-9 - (10-15) 10.2 (10-15) 11.2 (10-15) 12.2 (10-15) 13.2 (10-15) 14.2 (15-20) 19.7R105.1809.005.3.4 (10-15) 10.2 (10-15) 11.2 (10-15) 12.2 (10-15) 13.2 (10-15) 14.2 (15-20) 19.7R105.1819.1.4 (10-15) 10.3 (10-15) 11.3 (10-15) 12.3 (10-15) 13.3 (10-15) 14.3 (15-20) 19.7R105.1809.1.2 4-9 - (10-15) 10.2 (10-15) 11.2 (10-15) 12.2 (10-15) 13.2 (10-15) 14.2 (15-20) 19.7R105.1809.2.2 (10-15) 10.2 (10-15) 11.2 (10-15) 12.2 (10-15) 13.2 (10-15) 14.2 (15-20) 19.7Dimensions in mmNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN43

BALANCING CHART Boring ≥ 5.0 mmfor TOOLHOLDER TypeB105.0016.U1.01NPart numberR105.1823.005.1.5BoreØBore Ø5 6 7 8 9 10 11 12 13(10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1823.005.2.5 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1823.005.3.5 5-10 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1823.005.4.5 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1823.005.5.5 (10-15) 10.3 (10-15) 11.3 (10-15) 12.3 (10-15) 13.3 (15-20) 19.0 (25-30) 28.0R105.1823.1.5 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1823.2.5 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1823.3.5 5-10 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1823.4.5 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1823.5.5 (10-15) 10.3 (10-15) 11.3 (10-15) 12.3 (10-15) 13.3 (15-20) 19.0 (25-30) 28.0R105.1833.005.2.6(10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.1 (25-30) 28.1R105.1833.005.3.6 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.07-12R105.1833.005.4.6 (10-15) 10.4 (10-15) 11.3 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1833.005.5.6 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1833.2.6(10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.1 (25-30) 28.1R105.1833.3.6 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.07-12R105.1833.4.6 (10-15) 10.4 (10-15) 11.3 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1833.5.6 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1840.005.3.7(10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5R105.1840.005.4.7 8-13(10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5R105.1840.005.5.7 (10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5R105.1840.3.7(10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5R105.1840.3.7 8-13(10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5R105.1840.3.7 (10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5Dimensions in mmN44In the UNITED STATES call us toll free1 - 888 - 818 HORN

BALANCING CHART Boring ≥ 4.0 mmfor TOOLHOLDER TypeB105.0016.U1.01Part numberR105.1819.1.H4BoreØBore Ø4 5 6 7 8 9 10 11 12 13(10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1819.1.H4 4-9 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1819.1.H4 (10-15) 10.3 (10-15) 11.3 (10-15) 12.3 (10-15) 13.3 (15-20) 19.0 (25-30) 28.0R105.1823.1.H5 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1823.2.H5 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1823.3.H5 5-10 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1823.4.H5 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.0 (25-30) 28.0R105.1823.5.H5 (10-15) 10.4 (10-15) 11.4 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1833.2.H6(10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1833.3.H6 (10-15) 10.4 (10-15) 11.4 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.17-12R105.1833.4.H6 (10-15) 10.4 (10-15) 11.4 (10-15) 12.5 (10-15) 13.5 (15-20) 19.1 (25-30) 28.1R105.1833.5.H6 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (15-20) 19.1 (25-30) 28.1R105.1840.3.H7(10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.1 (10-15) 14.1 (15-20) 19.5R105.1840.4.H7 8-13(10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5R105.1840.5.H7 (10-15) 10.0 (10-15) 11.0 (10-15) 12.0 (10-15) 13.0 (10-15) 14.0 (15-20) 19.5Dimensions in mmNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN45

BALANCING CHART Boring ≥ 4.0 mmfor TOOLHOLDER TypeB105.0016.U1.01Part numberR105.4719.1.4R105.4719.3.4R105.4723.2.5R105.4723.4.5R105.4733.3.6R105.4733.5.6BoreØBore Ø4 5 6 7 8 9 10 11 124-9 (10-15) 10.3 (10-15) 11.3 (10-15) 12.3 (10-15) 13.3 (15-20) 19.0 (25-30) 28.05-10 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.5 (10-15) 14.5 (20-25) 24.07-12 (10-15) 10.2 (10-15) 11.2 (10-15) 12.5 (10-15) 18.0 (15-20) 19.0 (15-20) 19.8Dimensions in mmNN46In the UNITED STATES call us toll free1 - 888 - 818 HORN

BALANCING CHART Boring ≥ 3.0 mmfor TOOLHOLDER TypeB105.0016.U1.01Part numberR105.9013.01.1.3BoreØBore Ø3 4 5 6 7 8 9 10R105.9013.01.2.3R105.9013.1.3R105.9013.2.3R105.9019.01.1.43-8 (10-15) 10.6 (10-15) 11.6 (10-15) 12.6 (10-15) 13.7 (10-15) 14.6 (20-25) 24.0(10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (10-15) 14.4 (20-25) 28.0R105.9019.01.2.4 (10-15) 10.2 (10-15) 11.2 (10-15) 12.2 (10-15) 13.2 (10-15) 14.1 (20-25) 27.8R105.9019.01.3.4 4-9(10-15) 10.2 (10-15) 11.2 (10-15) 12.2 (10-15) 13.2 (10-15) 14.1 (20-25) 27.8R105.9019.1.4 (10-15) 10.4 (10-15) 11.4 (10-15) 12.4 (10-15) 13.4 (10-15) 14.4 (20-25) 28.0R105.9019.2.4 (10-15) 10.2 (10-15) 11.2 (10-15) 12.2 (10-15) 13.2 (10-15) 14.1 (20-25) 27.8R105.9023.01.1.5R105.9023.01.2.5R105.9023.1.5R105.9023.2.5R105.9023.3.55-10 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (10-15) 13.6 (10-15) 14.5 (20-25) 24.0Dimensions in mmNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN47

BALANCING CHART Boring ≥ 5.0 mmfor TOOLHOLDER TypeB105.0016.U1.02Part numberBoreØBore Ø5 6 7 8 9 10 11 12 13R105.1823.4.5.2R105.1823.5.5.25-10 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (25-30) 27.0 (30-35) 32.5 (20-25) 24.2R105.1833.4.6.2R105.1833.5.6.27-12 (10-15) 10.5 (10-15) 11.5 (10-15) 12.5 (25-30) 27.0 (30-35) 32.5 (20-25) 24.2R105.1840.4.7.2R105.1840.5.7.2R105.1840.7.7.2R105.4733.5.6.28-137-12(10-15) 10.0 (10-15) 11.0 (15-20) 17.0 (15-20) 18.0 (15-20) 19.0 (15-20) 19.8(10-15) 10.3 (10-15) 11.5 (10-15) 12.6 (10-15) 13.7 (10-15) 14.8 (20-25) 24.2Dimensions in mmNN48In the UNITED STATES call us toll free1 - 888 - 818 HORN

BALANCING CHART Boring ≥ 6.0 mmfor TOOLHOLDER TypeB110.0016.U1.02Part numberBoreØBore Ø3 4 5 6 7 8 9 10R105.9013.1.3(30-35) 30.0 (25-30) 26.0 (15-20) 18.0 (25-30) 27.5 (20-25) 24.2 (25-30) 29.06-11R105.9013.2.3 (30-35) 30.0 (25-30) 26.0 (15-20) 18.0 (25-30) 27.5 (20-25) 24.2 (25-30) 29.0R105.9019.1.4 8-13 (10-15) 10.0 (10-15) 11.5 (10-15) 13.0 (15-20) 19.0 (15-20) 20.0 (25-30) 28.9Dimensions in mmNIn the UNITED STATES call us toll free1 - 888 - 818 HORNN49

CARBIDE GRADESUNCOATED GRADESMG12 - a universal grade <strong>with</strong> good wear resistance. Used at low or medium cutting speedsfor machining steel, cast iron <strong>and</strong> non ferrous materialsCOATED GRADESTN35 - a very popular grade TiN coated used at low or medium cutting speeds. Alsorecommended for machining stainless steel or exotic alloyed materialsTI25 -a TiCN coated grade <strong>with</strong> high abrasion resistance. Recommended for machiningsteel <strong>and</strong> non ferrous materials at medium cutting speedsTF45 -a TiAlN coated grade. This coating has a very high temperature stability <strong>and</strong> highhardness <strong>and</strong> is only used for special applications.TH35 -new st<strong>and</strong>ard grade AlTiN - extreme temperature stability <strong>with</strong> high hardness <strong>and</strong>very good coefficient of friction.NN50In the UNITED STATES call us toll free1 - 888 - 818 HORN

CUTTING DATANominal cutting speeds <strong>with</strong> HORN gradesFeed rate IPRSUPERMINI ®MINI.0004"-.0008" .0004"-.0012".0008"-.002" .00012"-.004".0008"-.002" .0004"-.003"ISOMaterialHardnessBrinellCutting speed *v cft/mMG12 TN35 TI25 TF45 TH35 CB10/50C < 0,4% 125Carbon steelC > 0,4% < 0,6 % 15046-361 46-590 46-590 46-590 46-590C > 0,4% < 0,6 % 200annealed 180low alloyed steelquenched 27553-295 53-492 53-492 53-590Pquenched 300high alloyed steelannealed 200quenched 32563-295 63-295 63-400unalloyed 180Cast steellow alloyed 22063-361 63-590 63-590 63-590high alloyed 225martensitic, ferritic 200 63-295 63-295 63-295Maustenitic 180 53-263 53-263Cast iron 180-260 53-295 53-492 53-492 53-492 53-492KSpheroidal graphitecast iron180-260 53-295 53-425 53-425 53-492 53-492Malleable cast iron 130-230 53-425 53-425 53-492 53-492NiFe 59-246 59-246 59-246SNiCo 59-131 59-131 59-131NAl-alloy 46-722 53-1970 53-1970 53-1970Copper <strong>and</strong> brass alloys 46-722 46-2300 46-2300 46-2300H hardened material > 54 HRC 65-455Nv cis depending on the tool diameter <strong>and</strong> therefore of the maximum numbers of revolutions of the machine.In the UNITED STATES call us toll free1 - 888 - 818 HORNN51

CHOICE OF CARBIDE GRADESSynthetic cutting-tool materialPD10PD20Wear resistanceCutting speedToughnessFeed rate0110CB10CB5020304010203040N01102030Non ferrous metal High temp. alloys Hardened materialsCarbide Gradesuncoated coatedCarbide Gradesuncoated coatedMG12 TI25TF45SMG12 TN35 TF45HWear resistanceCutting speedToughnessFeed rateMG12TN35MG12TN35MG12 TN35TI25TI25TI25TF45TF45TF45TH35TH35TH35TH35N01P102030401020304001102030Steel Stainless steel Grey cast iron / AluminiumMKN52In the UNITED STATES call us toll free1 - 888 - 818 HORN