Parsons - 2010 Construction Management for AWV.pdf - SCATnow

Parsons - 2010 Construction Management for AWV.pdf - SCATnow

Parsons - 2010 Construction Management for AWV.pdf - SCATnow

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

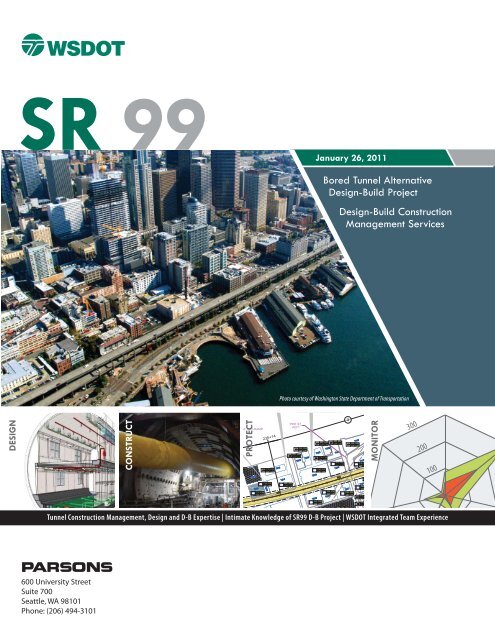

PARSONS600 University Street, Suite 700 • Seattle, WA 98101 • (206) 494-3101 • Fax: (206) 494-0960 • www.parsons.comJanuary 26, 2011Washington State Department of TransportationAlaskan Way Viaduct Program Office999 Third Avenue, Suite 2424Seattle, WA 98104Re:SR 99 Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesDear Sir or Madam:We are pleased to submit this proposal <strong>for</strong> the <strong>Construction</strong> <strong>Management</strong> services <strong>for</strong> the SR 99 Design-Build project. Inproviding <strong>Construction</strong> <strong>Management</strong> services to WSDOT, we will integrate and work closely with WSDOT, the SR 99project management team, and the design-builder to deliver the SR 99 Design-Build project. The <strong>Parsons</strong> team brings theperfect balance of a professional history of worldwide tunneling construction management (CM) experience andextensive CM experience on transportation design-build tunnel contracts, providing WSDOT the reassurance of a trustedand experienced team that understands its role on this project. <strong>Parsons</strong> will lead our team, which includes Halcrow Inc.,CMTS Inc., The VOSK Group, and a number of recognized technical support experts. Although not required, we arepleased to integrate CMTS, a minority-owned firm, and VOSK, a DBE firm, into our team, and continue our dedication tosupporting these businesses. Collectively, we have per<strong>for</strong>med every role – construction manager, equity partner,program manager, designer, and contractor – and can offer this experience to WSDOT.Leadership with Careers Completely Dedicated to Tunnel <strong>Construction</strong>We believe there is no one better suited to successfully anchor our team than our Resident Engineer, Greg Colzani. He isa recognized expert in soft ground tunneling, who has been practicing CM <strong>for</strong> 30 years. He has filled key roles <strong>for</strong>signature tunnel projects including the Willamette River CSO program in Oregon, the I-70 Hanging Lake Tunnels inColorado, and the South Bay Ocean Outfall in Cali<strong>for</strong>nia. As the <strong>Construction</strong> Manager in Portland, Greg managed anintegrated client and consultant CM team to work collaboratively with the contractor during preconstruction tocomplete the design, evaluate methods, and develop project plans. This process saved millions of dollars through theintroduction of risk-reducing, innovative construction technologies to the country, including slurry TBM technology andsteel-fiber rein<strong>for</strong>ced tunnel segments. Not only a tunneling specialist, Greg has CM experience with highway tunnelcontrol and ventilation systems, installation, integration, and commissioning.We are providing the added value leadership of Steve Minassian, PE, to coordinate all CM service activities. Similar toGreg, Steve has spent his career in tunneling. Over the past 25 years, he has fulfilled many diverse roles serving thetunneling industry. Steve has served as the Design Manager and <strong>Construction</strong> Manager on several high-profile, softground tunneling projects, as well as serving as the Project Manager <strong>for</strong> the Port of Miami Tunnel project, where he wastasked with leading the design-build joint venture’s design ef<strong>for</strong>ts <strong>for</strong> the largest-diameter TBM tunnel in the UnitedStates to date. Steve has participated actively in risk management, partnering, and dispute resolution board proceedings.Professional History Provides Greatest Assurance of SuccessThe <strong>Parsons</strong> team is currently working on or has completed work as the CM on 10 recent,complex tunnel design-build projects. We understand the differences of this role versus a traditional design-bid-buildproject. As a result, we have developed specific CM plans and processes, proven tools, and qualified personnel to managethe cost, schedule, and quality objectives of the design-build projects. Locally, our team has made a commitment to thisregion by delivering transportation solutions since 1929, including key WSDOT projects such as the SR 532 CorridorImprovements Design-Build project; the I-405 Corridor Program; and the Tacoma Narrows Bridge project. We look<strong>for</strong>ward to continuing to partner with WSDOT, and will draw on our experience with WSDOT’s procedures andregulations.

Halcrow is a premier tunnel designer and constructor, with marquee projects around the world.Their roles in major tunneling projects include design, engineering support during construction, and constructionmanagement, which gives them a complete perspective on different types of project delivery methods, including designbuild.Most importantly, both <strong>Parsons</strong> and Halcrow have design-build experience as an equity partner, so we know whatit takes to manage a project of this size.We offer an outstanding group of CM professionals who have experience working on many of the world’s largesttunneling projects, including the Channel Tunnel Rail Link, the Dubai Metro Red and Green Lines, the Al Salam StreetTunnel, and the Caldecott Tunnel Improvement Program. In addition, our team includes technical experts fromprofessional and academic backgrounds, who are considered world leaders in their fields. They will provide us with themost innovative expertise and technical advice on specialized disciplines such as settlement mitigation and hyperbaricinterventions, so that we can provide the strongest possible CM services support to WSDOT.Our individuals’ and firms’ experience alone differentiates our team from the rest. Additionally, our significant ef<strong>for</strong>ts aspart of the Seattle Tunneling Group, in which we prepared a full proposal, a comprehensive cost/time risk assessment,and a 30 percent design to bid on the bored tunnel project, uniquely qualifies us to assist WSDOT in managing the SR 99CM Services project. <strong>Parsons</strong> and Halcrow have developed a comprehensive understanding of the project’s risks andattributes to the community, and our experience in soft-ground, pressurized-face tunneling as both a designer and aconstructor gives us the capacity to assist WSDOT with the CM of this major project.As two top-tier design-build firms with additional strong support, the <strong>Parsons</strong> team brings an understanding of theimportance of partnership, integration, and team-building with WSDOT. We understand that the right combination ofmanagerial and technical expertise will provide the most benefit to WSDOT, while allowing us to seamlessly integratewith the project team.Combined, our tunnel CM experience, design and design-build expertise, thorough knowledge of the SR 99 Design-Buildproject, and integrated team experience with WSDOT, provides WSDOT with a uniquely qualified team to support its CMprogram and ensure successful delivery of the SR 99 Design-Build project.We thank you <strong>for</strong> the opportunity to present our local team and proposed approach to this project. Further, we confirmthat <strong>Parsons</strong> has no conflict of interest in submitting this package, and all staff members on our team are expected toavoid conflicts of interest at all times.Our single point of contact <strong>for</strong> this project is Rick Chapman, PE, who can be reached at:<strong>Parsons</strong>Attn: Rick Chapman, Vice President, Area Manager600 University Street, Suite 700Seattle, WA 98101Phone: (206) 494-3109/Fax(206) 494-0960Email: Rick.Chapman@parsons.comWe thank you <strong>for</strong> the opportunity to submit these qualifications and look <strong>for</strong>ward to working closely with you again.Sincerely,PARSONSThomas Barron, President, <strong>Parsons</strong> Transportation Group Inc.

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99BExecutive SummaryExecutive SummaryThe SR 99 Bored Tunnel Alternative Design-Build Project, which will replace the aging Alaska Way Viaduct and restore thewaterfront as a usable community space, is yet another opportunity to reshape the face of Seattle. As part of the Seattlecommunity, we look <strong>for</strong>ward to being a part of this landmark project that will build the largest bored tunnel in the world.The SR 99 design-builder will construct a first in the world, 58-foot diameter tunnelusing an earth pressure balance (EPBM) “mega” machine. The tunnel project has severalchallenges, including varying soft soil conditions, submerged construction environments,and significant site constraints. There are many risks related to constructing a tunnel alongthe proposed alignment. One of the greatest risks is ground settlement caused by overexcavationat the face of the tunnel excavation, which can lead to significant settlementof buildings and adjacent infrastructure. For the bored tunnel project, settlement is ofparticular concern due to the number of sensitive buildings and critical infrastructure inthe tunnel’s vicinity. We understand these risks and provide the best team to assist WSDOTin managing the project beginning on Day 1.The <strong>Parsons</strong> Team’s Local and Worldwide CM Expertise Provides a CM Approach <strong>for</strong>Design-Build That ProtectS WSDOT’s InterestsThe <strong>Parsons</strong> team is ideally suited to provide first-classCM services that will complement WSDOT’s CM program,to help ensure that the design-builder delivers a qualityproject safely. We have assembled a team that includesour strongest, most experienced tunnel constructionmanagers, supported by recognized tunnel designand construction professionals from both industry andacademia. We can mobilize <strong>Parsons</strong>’ and the team’scombined staff of over 21,000 employees. Our teammembers and firms possess the unique set of skillsdescribed below to help WSDOT deliver a successfulproject.• Experience in large diameter transportation tunnelCM, including design-build CM• Thorough knowledge of the SR 99 Bored TunnelAlternative Design-Build project• Integrated team experience with WSDOT, and a clearknowledge of WSDOT’s procedures and processes.Through our success with delivering over 250 complextunnel projects worldwide, we have developed keysystems and processes particular to the management oftunnel construction. For example, we have developed<strong>Parsons</strong>’ CM Experience in TunnelDesign-Build Protects WSDOT’s Interests<strong>Parsons</strong> is uniquely qualified to provide CM services <strong>for</strong> the SR 99 Design-Buildproject due to our extensive involvement in design-build projects, where our roleshave ranged from CM to <strong>Construction</strong> Joint Venture Lead Partner. As such, we clearlyappreciate our role augmenting the SR 99 Design-Build project CM organization toprotect WSDOT’s interests in delivering a safe, and efficient roadway of the highestquality. <strong>Parsons</strong> has provided CM services worldwide <strong>for</strong> major tunnel design-buildprojects, including the following current and past projects:• New Jersey Transit ARC Program−−Manhattan Tunnels−−Palisades Tunnels−−Hudson River Tunnels• Dubai Light Rail Transit−−Red Line Tunnels−−Green Line Tunnels• Dulles People Mover Tunnel• Al Salam Street Tunnels• Channel Tunnel Crossing• Channel Tunnel Rail Link• Midtown Tunnel, Hampton Roads, VA• Straights of Messina Crossing, Italy• Southern Nevada Water Authority(SNWA) – Intake No. 34

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99PDA-based inspection data collection systems that provides data supporting time and motion studies, productivity andanalysis of delay claims. We have developed project and program-wide CM plans <strong>for</strong> complex tunnel projects including theARC Tunnels in NJ and the Water System Improvement Program (WSIP) in San Francisco.Through our significant ef<strong>for</strong>t in this design-build pursuit, weprepared a comprehensive risk-based proposal, conducted acomplete settlement and structure protection analysis, andcompleted a 30 percent design. This process gives our team anunequalled, in-depth understanding of the project, andstrengths in the following areas:• Full understanding of WSDOT’s operational and design requirements• Risk identification and mitigation• Geological and geotechnical conditions• Comprehensive structures analysis• TBM selection and design• Comprehensive systems integration study• Continuity of staffThis experience, coupled with our risk-based approach, gives us a running startat assisting WSDOT with design reviews, evaluation of innovative ideas by thedesign-builder, and managing risks.Our only interest is to provide WSDOT withevery tool available to ensure project success.We are here to “manage”, not to “construct”.UtilitiesStructuresand Geotech.RailroadRight of way700600500400<strong>Construction</strong>300200100Partnershipand StakeholdersDesign /PS&EEnvironmentaland HydraulicContractingand procurementOur detailed risk assessment enabled the SeattleTunneling Group to apply risk-based bid costs <strong>for</strong>each element of work.200Bored TunnelUTLSTGSettlements andmitigation measuresRR300200600500400300200100CNSROWAccidents, QualityProven technical and management approachpavement, etc.)ScheduleOne of our team’s primary goals is working collaboratively with WSDOT and the Design-Builder, and leveraging our uniqueexpertise to deliver a quality project safely, on time, and with manageable risks. Our approach to the technical challengesArchitecturalCut & Coveron the project will capitalize on our knowledge of CM <strong>for</strong> major tunnel projects we have successfully completed and theknowledge of our team members who have addressed first-hand the challenges facing this Design-Builder.Designissues15010050Potential changesto roadway design(including verticaland/or horizontalalignment, earthwork,Safety, quality100We have highlighted nine major risk categories and detailed a comprehensive strategy to assist WSDOT in mitigating them.One of the major risks, tunnel-induced settlement and mitigation has been thoroughly investigated by our team whichgives WSDOT added-value in<strong>for</strong>mation to proactively monitor the Design-Builder’s per<strong>for</strong>mance.Our approach to assisting WSDOT in the safe delivery of CM Services will build on our successful history in partnering withWSDOT and other consultants in a co-located, integrated team environment. We will assist WSDOT in developing a workableCM plan, support the execution of that plan by providing the appropriate level of personnel and technical expertise, andmaximize WSDOT training opportunities. We will continue our successful delivery of CM Services through the consistentapplication of WSDOT’s policies and procedures to implement the requirements to the design-build contract.Our technical and managerial approach discussed in detail in Section E demonstrates our understanding of the projectrisks and how to manage them effectively.Our Leadership Team Drives Quality Per<strong>for</strong>manceAs an added value to WSDOT, we will provide Steve Minassian as our CM Services Manager. Steve will be tasked withcoordinating all staffing and planning <strong>for</strong> our team, and will provide important technical and managerial support to thevaluable resources offered to WSDOT. Steve has made a career of the tunnel business with a 25-year history and a leadershipstyle that demonstrates he will collaborate well with WSDOT and the project team. Steve has served as the <strong>Construction</strong>Manager on several complex, large-diameter, soft ground tunnel projects, including the North Shore Connector inPittsburgh, PA. He was the Design and Project Manager <strong>for</strong> the Port of Miami Tunnel project, where he led the design-buildjoint venture’s design ef<strong>for</strong>ts <strong>for</strong> the largest-diameter TBM tunnel in the United States. Working <strong>for</strong> tunnel contractors, he5

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99was responsible <strong>for</strong> providing efficient, safe, and cost-effective solutions to solve day-to-day construction issues. Steve hasparticipated actively in risk management, partnering, and dispute resolution board proceedings.Our Resident Engineer, Greg Colzani, will anchor our team. Greg is a recognized expert in CM of large-diameter, softground tunnel projects, with over 30 years of tunnel CM experience. In the roles of <strong>Construction</strong> Manager and ResidentEngineer, he has provided expertise in the selection of TBM machines as part of evaluations of contractors’ alternativeproposals on the Hollywood Water Quality Improvement Project and the South Bay Ocean Outfall projects in Cali<strong>for</strong>nia,and the Willamette River CSO program in Oregon. He has comprehensive experience in a wide variety of shaft constructionmethods, including complex deep slurry walls, secant installations, jet grouting, ground freezing, drilled and conventionallyexcavated shafts. Greg served as the CM <strong>for</strong> the Willamette River CSO program, managing an integrated city and consultantstaff of nearly 40 people to work collaboratively with contractors during pre-construction and construction phases of thesoft ground tunnel project. Greg has also managed the installation, testing, and commissioning of tunnel ventilation andcontrol systems, including the H-3 tunnels in Hawaii and the I-70 Hanging Lake tunnels in Colorado. Greg is accomplishedin the risk assessment/risk management process.Our Pre-<strong>Construction</strong> Lead, Jon Kaneshiro, will assist in design reviews during pre-construction. Jon was the DesignManager <strong>for</strong> our SR 99 Design-Build pursuit, and will provide a seamless interface during this phase of the project. Jonhas 30 years of design management experience in planning, construction, and seismic analysis of tunnels, foundations,mass excavations, and underground projects. His expertise in tunnel engineering includes over 150 tunnels, 45 of whichhe served as Engineer of Record. As the Design Manager on more than 20 contracts, Jon’s experience includes the finaldesign of unique bolted, gasketed segmental liners. Jon’s understanding of the design and construction challenges of softground tunneling, liquefaction, fault crossing design, and the final design of deep excavations and tiebacks includes localknowledge from preliminary engineering, methodology studies, and design reviews in Seattle - the Beacon Hill tunnels,the Metro Downtown Seattle Transit (Bus Tunnel) Project, and the Sound Transit Design-Build of the Central Link ExtensionTunnels. For continuity and added value, we have retained the same key design team from our design-build pursuit toeliminate any learning curve and begin assisting WSDOT on Day 1.Our Systems Integrator, Doug Slakey, has more than 28 years of experience in the planning, engineering, design,and management of civil infrastructure projects, with over 15 years of his professional practice spent in the planning,design, and construction of highway tunnel systems, communications system architecture, and ITS. His project experienceincludes highway, railroad, and mass transit tunnels; railroad, urban transit, urban, and rural highways; and bridges. Dougwas responsible <strong>for</strong> the systems integration <strong>for</strong> the I-70 Hanging Lake Tunnels project in Colorado, which included a semitransverseventilation system with vane axial fans, and a complete traffic monitoring and control system. He was the designsystems integration lead <strong>for</strong> the Caldecott Tunnel Improvement Program, which is currently under construction on SR 24in the hills above Oakland, CA.Why the <strong>Parsons</strong> Team?Our team is ready to mobilize, and is available <strong>for</strong> this project on Day 1. The <strong>Parsons</strong> team provides the perfect blendof global talent, local experience, tunnel CM expertise, and a strong understanding of design-build delivery.Soft ground tunnel <strong>Construction</strong> <strong>Management</strong> experience. The <strong>Parsons</strong> team includes individuals with a long historyin leading CM <strong>for</strong> design-build of the largest and most technically-challenging deep tunnels in the world.Thorough understanding of the SR 99 Design-Build Tunnel. Our experience in contributing to the Seattle TunnelingGroup’s proposal <strong>for</strong> the SR 99 Design-Build project provides us with a detailed perspective of project risks andchallenges.Unique experience working in a WSDOT integrated team. The <strong>Parsons</strong> team has demonstrated their ability toeffectively work with WSDOT and consultants side by side to deliver projects meeting WSDOT’s goals and requirements.6

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99CTeam FirmsThe <strong>Parsons</strong> team was <strong>for</strong>med to provide WSDOT with the personnel and project experience it needs to successfully deliverthe SR 99 Design-Build project. In addition to technical and managerial skills, we see each of the following criteria as criticalto successfully completing the CM team:•Experience in construction management, tunnelconstruction, design and design-build, and a depth ofresources with the expertise to solve problems quicklyand effectively.•Thorough knowledge of the SR 99 Bored TunnelDesign-Build project, including understanding thescope, risks, and associated costs at a detailed level.•Integrated team experience with WSDOT and a clearknowledge of WSDOT’s procedures and processes.Each of these is important, and all three provide WSDOTwith a team that can seamlessly join WSDOT’s currentteam of personnel and consultants, with a minimallearning curve. Figure C.1 illustrates the advantages andbenefits WSDOT will receive by working with a team suchas ours, which has all of these qualities.Figure C.1 – Advantages and Benefits of Our TeamTeam Firms<strong>Parsons</strong> and Halcrow were two members of SeattleTunneling Group’s design team. We have complementedour already knowledgeable team with specific firms andindividuals to bring the best talent to WSDOT. Othermembers of our team are:• The VOSK Group, a certified Disadvantaged Business Enterprise (DBE), is an association of professionals who haveworked together over the past 20 years on various large, civil projects in the Puget Sound Area. VOSK specializes inproject and construction management services. Vic Oblas, one of VOSK’s principals, has been brought to the team <strong>for</strong>his knowledge of the SR 99 Design-Build project and the complexities (both technical and managerial) it brings, as wellas his experience with tunneling operations in downtown Seattle.• CMTS Inc. , a minority-owned firm, will provide quality tunnel inspectors who bring specialized experience and depth ofresources to the team. <strong>Parsons</strong>, and specifically our proposed Resident Engineer, Greg Colzani, has extensive experienceworking with CMTS on tunneling projects.• CRS Engineering Consultants, Ltd is a UK-based firm that brings world-class segmental lining inspection experience tothe team. Chris Smith, CRS’ principal, is designated as our special inspector <strong>for</strong> segmental linings.• HealthForce Partners LLC is a workplace health company specializing in occupational health services. Edmond Kay,MD, our hyperbaric specialist, is a recognized regional leader in hyperbaric medicine.7

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Table C.1 illustrates how the <strong>Parsons</strong> and Halcrow, complemented with the skills of the other team members, brings toWSDOT an array of skills and experience that meets its required CM managerial and technical needs, while bringing addedvaluein project knowledge, WSDOT knowledge, and relevant local experience.Table C.1 –Team QualificationsKEY TECHNICAL ELEMENTSPARSONSHALCROWCMTSVOSKSoft ground pressurized face TBM tunnels • • • •TBM tunnels constructed below ground water • • • •TBM instrumentation and per<strong>for</strong>mance analysis • • • •Pre-cast gasketed segmental concrete lining systems • • • •Hyperbaric interventions <strong>for</strong> TBM maintenance/repair • • • •Geotechnical instrumentation <strong>for</strong> structure monitoring • • • •Deep ground improvement techniques • • • •Control tunnel construction-induced ground movement • • •Deep excavation, below groundwater • • • •Support of major structures and facilities • • • •Control/mitigation settlement of structures and utilities • • •Systems integration of roadway and tunnel systems • • •Schedule and claims analysis • • •Underground safety program expertise • • •Resident engineering and inspection of tunnel projects • • • •VALUE ADDED SERVICE CAPABILITIESIntegrated team co-located with owner • • • • •Detailed knowledge of SR 99 Design-Build project scope • • • •Risk analysis of SR 99 Design-Build project • • •Understanding of SR 99 Design-Build project costs • •WSDOT Experience • •Commissioning • • •EXPERTSOur organizational chart, shown on the following page, shows our integrated team <strong>for</strong> per<strong>for</strong>mance of all CM services.Our key personnel <strong>for</strong>m the framework of the organization and the additional staff represent further resources who areavailable <strong>for</strong> this program. The organizational chart also indicates the functional authority, lines of communications, andresponsibility of the positions.The <strong>Parsons</strong> team has extensive local and worldwide experience in deep tunnels, soft ground large bored tunnels, andtunnels with extensive systems installation and integration. We will draw on our knowledge of the SR 99 Design-Buildproject as well as this past work. The nine projects presented in this section demonstrate our team’s extensive experiencedesigning and constructing tunnels similar to the SR 99 Design-Build project. This experience and expertise in large boredtunnels will greatly complement our CM services work.8

* Key StaffFirmBored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> Services SR 99(C) CMTS, Inc.(CRS) CRS EngineeringConsultants, Ltd(H) Halcrow, Inc.(HF) Health<strong>for</strong>ce Partners, LLC(V) The VOSK Group<strong>Parsons</strong> Employee Unless IndicatedExecutive PanelRick Chapman, PEMichael JohnsonRalph Trapani, PEMartin Knights, C. Eng (H)Executive DirectorMichael JohnsonWSDOTCM Services ManagerSteve Minassian*, PESettlementEdward Cording, PhDSegmental LiningChris Smith, C. Eng & FICE (CRS)*Technical AdvisorsHyperbaric InterventionsEdmond Kay, MD, (HF)StructuresGreg Orsolini, PE, Kimo Okamitsu, PE, SEPre-<strong>Construction</strong>CM Support Services Team<strong>Construction</strong>Pre-<strong>Construction</strong>Services LeadJon Kaneshiro, PE*Task Force TeamsDesign Review CoordinatorDon Clark, PETunnelJon Kaneshiro, PE* &Anthony Harding, C. Eng (H)Support of ExcavationJon Kaneshiro, PE* & Tony Stirbys, LEGTunnel Systems/MechanicalDoug Slakey, PE*, Robert Desrosiers,John Bumanis, PE, Paul Bates, C. Eng (H),& Peter Woodburn, C. Eng (H)Settlement MonitoringTony Stirbys, LEG, Jan Babendererde*,& Edward Cording, PhDTBM DesignJon Kaneshiro, PE*, Greg Colzani*,Steve Minassian, PE*,& Jan Babendererde*Interior StructuresBill Elkey, PE, SE,Arun Bhalaik, PE, (H),& Greg Orsolini, PEMOTVic Oblas, PE (V)<strong>Construction</strong> Planning LeadGreg Colzani* & Bob Lenz, PE, CCM*<strong>Construction</strong> Planning TeamCM Plan DevelopmentBob Lenz, PE, CCM*, Eric Ostfeld, PE,& Adam Fredericks, PEMonitoring andInstrumentation PlanningTony Stirbys, LEG, Jan Babendererde*,& Shimi Tzobery, PEHyperbaric SpecialistsRobert Rodgers, Jan Babendererde*,& Edmond Kay, MD (HF)Safety ManagerDaniel Weathers* &Robert Meshew, C. Eng, (H)SchedulerDan Brown* & Ed MastersonTunnel Systems IntegratorDoug Slakey, PE* & Vic Oblas, PE (V)Monitoring/InstrumentationEngineerTony Stirbys, LEG & Jeremy Wehner, PEClaims/Estimating/Change<strong>Management</strong>Ralph Trapani, PE, Gerald Bonner, PE,& Rhonda KolodjiInteragency/Commissioning CoordinatorVic Oblas, PE (V)WSDOT Compliance and ReportingRhonda Kolodji, Bob Lenz, PE, CCM*,& Don Clark, PERisk MitigationBob Lenz, PE, CCM*, Greg Colzani,& John Donatelli, PEQuality Verification PlanBen Fardi, PE* & Eric Ostfeld, PETunnel Chief InspectorMark Bower, C. Eng (H)*Resident Inspection - TunnelsTunnel Chief InspectorMark Bower, C. Eng (H)*Tunnel Excavation/LiningAlf Evers (C)*, Fermin Longcob*,Gary Daniel*, Robert Meshew, C. Eng (H)Grouting/Ground ImprovementBryant Sanders* (C), Lee Moore (C)& Tony Stirbys, LEGTBM Fabrication/Assembly/TestingJan Babendererde*TBM Maintenance/Intervention MonitoringJan Babendererde* & Shimi Tzobery, PESegment FabricationChris Smith*, C. Eng & FICE (CRS)& Mark Bower, C. Eng (H)*Hyperbaric SpecialistsRobert Rodgers, Jan Babendererde*& Edmond Kay, MD (HF)Tunnel Resident EngineerGreg Colzani*Chief InspectorStructuralJeff Lavinder, PE*Resident Inspection - StructuresInterior Structure PrecastFabricationChris Smith, C. Eng & FICE (CRS)*& Mark Bower, C. Eng, (H)*Interior Tunnel StructuresAlf Evers* (C), Nghia Giang*,& Jeff Lavinder, PE*Vent Building Mechanical/FinishesGordon Chen* & Tim DaleyTunnel and Traffic SystemsJoshua Cheatham, PEOff-Site Materials InspectionNghia Giang*9

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99ARC Tunnel Project/Trans-Hudson Express Tunnel ProjectNewark, NJPROJECT DETAILSClient Representative:Newark, NJContract Dates:6/09 - 10/10Total Dollar Amount:$8.7 billionServices Provided:<strong>Construction</strong> <strong>Management</strong>PROJECT BACKGROUNDThe CM Consortium tri-venture was contracted by New Jersey Transit <strong>for</strong> project control and construction management(PCCM) services in support of the Access to the Region‘s Core (ARC) project, and selected the ARC alternative known as theTrans-Hudson Express Tunnel Project. This project doubles the rail capability from New Jersey into midtown Manhattanthrough construction of the following:• Plat<strong>for</strong>m, concourse, and track improvements to the existing Frank R. Lautenberg Station in Secaucus, New Jersey• Two new single-track tunnels beneath the New Jersey Palisades (hard rock TBM tunnels) and the Hudson River (softground earth pressure balance TBM (EPBM) tunnels) connecting with four single-track tunnels in Manhattan (hard rockTBM tunnels)• <strong>Construction</strong> of the New York Penn Station Expansion to the north under 34th Street between 6th and 8th Avenues• Improvements to rail infrastructure in New Jersey to provide expanded one-seat-ride opportunities to midtownManhattan from various rail lines• Supporting investments such as electrification, traction power, track improvements, rail yards, signal systems, and facilitiesSignificant Challenges and/or InnovationsAlthough the project was suspended during the initial stages of construction, the CM Consortium developed numerousinnovations during pre-construction. Responding to public concerns <strong>for</strong> providing safe, reliable transportation thatpromotes sustainable commuting patterns was at the core of the ARC project. Rail transit promotes sustainability byreducing emissions and providing an efficient, economical, and environmentally conscious way to travel. By doubling therail capability from New Jersey into Midtown Manhattan, the ARC project would have allowed more people to use this“green” <strong>for</strong>m of transportation as their primary means of commuting.Sustainability is also being incorporated into the project through various construction methods. For instance, the New YorkPenn Station Expansion (NYPSE) cavern, the largest underground station in Manhattan, was scheduled to be constructedusing green building practices that reduce water usage and heating and cooling loads. During construction, the contractorwould have been required to meet significant guidelines with respect to air quality and emissions.Roles of Major Participants<strong>Parsons</strong> is the managing partner <strong>for</strong> the CM Consortium tri-venture. The CM Consortium is contracted to per<strong>for</strong>m servicesthat align with a conventional construction management function and a project controls/oversight function. Majorservices included in the CM Consortium’s scope include review of preliminary engineering design work <strong>for</strong> constructability,review of geotechnical methodologies, development of a project control plan, review of the baseline budget preparedby the partnership design team, and resident engineering and inspection services. In addition, the CM Consortium isrequired to provide various other services, including developing a plan to control the scope and budget, supporting aproject management plan that integrates design and construction, developing a risk management plan, and developingthe Procedures Manual, which is intended to document the applicable quality management responsibilities of the CMConsortium through the life of the project.12

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Al Salam Street TunnelAbu Dhabi, UAEPROJECT DETAILSClient Representative:Abu Dhabi MunicipalityContract Dates:5/2008 - 1/2012Total Dollar Amount:$1.4 billionServices Provided:Designer, Engineering Support During<strong>Construction</strong>, <strong>Construction</strong> <strong>Management</strong>PROJECT BACKGROUNDAl Salam Street is a major urban arterial in Abu Dhabi’s central business district. <strong>Parsons</strong> was awarded a contract to designand supervise construction of major improvements to upgrade Al Salam Street to a freeway level of service. The projectcovers a total length of 9,800 feet, 8,200 feet of which will be a combination of depressed roadways and tunnels.The $1.4 billion project involves design and construction supervision of a major tunneling project in the heart of Abu Dhabi’scentral business district. The tunnel will carry four lanes of traffic in each direction from the Port Zayed area to beyond theintersection with Al Falah Street. Tunnels to connect Al Corniche Road with Al Salam Street are also being constructedas part of this project. The project included major detour work to minimize disruptions in a very densely populated partof the city. In addition, the project involves extensive utility relocations, while preventing disruption of services duringconstruction.Over the length of the project, the new tunnel adds four lanes of uninterrupted traffic-carrying capacity, resulting in acapacity addition of more than 6,000 vehicles per hour to this vital area of the city.The state-of-the-art tunnel safety and management system will coordinate ventilation, fire detection and suppression,lighting, public address, environmental management, electrical power supply, emergency broadcasting, radiore-broadcasting, security and surveillance, traffic detection and control, and traveler in<strong>for</strong>mation to a centralized monitoringand control facility.Significant Challenges and/or InnovationsIn anticipation of this major project, <strong>Parsons</strong> co-hosted a series of <strong>for</strong>ums to prepare short-listed contractors <strong>for</strong> tendering.The <strong>for</strong>ums offered the opportunity <strong>for</strong> potential contractors to keep updated with project developments, <strong>for</strong> what will beone of the largest and most complex construction projects ever undertaken in Abu Dhabi. This better prepared them totender and have the resources required ready, should they be awarded the contract.Roles of Major Participants<strong>Parsons</strong> designed and is supervising construction of two new tunnel interchanges on Al Salam Street through thedense business district of the capital highland city. Al Salam Street’s through traffic will be depressed below surfacelevelintersections. The depressed roadway <strong>for</strong> each interchange, carrying four lanes of traffic in each direction, will beapproximately 2,800 feet in length. At the surface, signalized intersections will serve local traffic movements to the adjacentresidential areas. Ramps will provide access to and egress from Al Salam Street.13

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Channel Tunnel Rail LinkLondon, UKPROJECT DETAILSClient Representative:London and Continental RailwaysContract Dates:10/98 - 11/07Total Dollar Amount:$9.2 billionServices Provided:Procurement Manager, Designer,<strong>Construction</strong> Manager, Engineering SupportDuring <strong>Construction</strong>PROJECT BACKGROUNDThe Channel Tunnel Rail Link (CTRL) is a 68-mile-long high speed rail line linking the existing Channel Tunnel to St. PancrasTerminus Station in London. Some of the major components of the project included:• An 11-mile-long, twin-bore tunnel including a 26.7-foot excavated diameter TBM-driven tunnel under central London,lined with steel-fiber, rein<strong>for</strong>ced concrete segments• A 1.5-mile-long, twin bore tunnel using including a 26.7-foot excavated diameter TBM-driven tunnel under the RiverThames, lined with steel-fiber, rein<strong>for</strong>ced concrete linings, and 4,250 feet of cut-and-cover approach tunnel• A 2-mile-long, single bore, twin track New Austrian Tunneling Method (NATM) tunnel (46 feet equivalent diameter) throughthe North Downs ChalkThe type of tunnel lining varied <strong>for</strong> each construction type. Steel-fiber, rein<strong>for</strong>ced precast concrete segments were used inconjunction with EPBMs. Associated mechanical and electrical equipment, including the overhead catenary, was installedwithin the tunnels. Final completion of the tunnel included installation of track, slab, and rail, a 2.6-foot-wide inspectionwalkway, a 4.9-foot emergency egress walkway, and fire/life safety systems. The project has won several national engineeringawards.The CTRL project included a state-of-the-art ventilation system to control smoke during fires in the tunnel. The ventilationsystem required the construction of five ventilation shafts within the London section of the project. In addition, the shaftsalso provided emergency egress and pressure relief to reduce transient pressures.Significant Challenges and/or InnovationsThe $9 billion CTRL project was the largest and most complex civil engineering project ever undertaken in Europe, spanning 10years and involving 45 main contractors to construct. The project pioneered the use of steel-fiber, rein<strong>for</strong>ced concrete segmentaltunnel linings <strong>for</strong> TBM-driven tunnels. This was also the first and largest use of polypropylene fibers in a segmental tunnel liningto improve per<strong>for</strong>mance in the event of a fire.The tunnel section in central London passes under approximately 3,000 domestic and industrial buildings, 67 bridges, 7.4miles of surface railways, 600 utility crossings, and under or over eight operational railway tunnels. One of the project team’spriorities was to comprehensively assess potential ground movements and impacts on structures along the alignment.The TBM tunnel construction necessitated extensive underpinning, ground improvement, and monitoring work to protectmany of these structures.Roles of Major ParticipantsHalcrow had overall design responsibility <strong>for</strong> all underground structures, provided CM services and engineering supportduring construction, and was an integral part of the procurement team.15

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99I-405 Corridor ProgramBellevue, waPROJECT DETAILSClient Representative:WSDOTContract Dates:03/2002 - 03/2012Total Dollar Amount:$1.5 billionServices Provided:Design and CM Services <strong>for</strong> Design-Builid andDesign-Bid-Build ProjectsPROJECT BACKGROUNDThe I-405 Corridor Program includes the design and construction of $1.5 billion worth of improvements along the I-405corridor. The program is comprised of seven design-build and five design-bid-build projects.Among the I-405 Corridor Program’s many successes is the project team’s goal to leave the environment better than wefound it. As part of the GEC, <strong>Parsons</strong> helped develop the environmental compliance database used by design-buildersto track progress and monitor the successful completion of environmental commitments made in the environmentaldocuments and permits. To date, the ten I-405 projects that have been awarded are on schedule, within budget, and havemet all legislatively mandated milestones.Significant Challenges and/or InnovationsOn the I-405/NE 8th St. to SR 520 Braided Ramps Project, <strong>Parsons</strong> worked with WSDOT to streamline the right-of-wayacquisition process. Appraisals were started prior to final approval of the right-of-way plans, shortening the overall right-ofwayacquisition process by as much as six months.<strong>Parsons</strong> helped WSDOT to assign risk more appropriately, and there<strong>for</strong>e receive more competitive bids. <strong>Parsons</strong> helpeddevelop the process that integrates RFP production, design, and cost estimating, which ultimately helped WSDOT maximizeits available budget.<strong>Parsons</strong> developed a self-directed design quality management program <strong>for</strong> the I-405 Corridor Program, which was basedon <strong>Parsons</strong>’ quality management plan, successfully used on the Tacoma Narrows Bridge Design-Build project. <strong>Parsons</strong>’independent quality auditor reviewed and recommended several process improvements to the environmental qualityprocess, which were immediately implemented, and WSDOT has adopted the process as their standard in developingenvironmental documents.<strong>Parsons</strong> facilitated the shift in responsibility <strong>for</strong> QA/QC from WSDOT to the design-builder, and provided quality verificationinspectors with experienced personnel from the Tacoma Narrows Bridge project.<strong>Parsons</strong>’ staff wrote the traffic management section of the RFPs to minimize inconvenience to the public and maximizesafety during construction. We also review design-builder traffic management proposals, coordinate with the NorthwestRegion Traffic Office, and ensure implementation during construction.Roles of Major ParticipantsAs a member of the general engineering consultant (GEC) co-located team, <strong>Parsons</strong> is providing design, programmanagement, preparation of RFQs and RFPs <strong>for</strong> design-build projects, and construction management services <strong>for</strong> WSDOT.<strong>Parsons</strong> has many full-time managerial and technical staff overseeing this work.16

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Willamette River CSO ProgramPortland, ORPROJECT DETAILSClient Representative:City of Portland, Bureau ofEnvironmental ServicesTotal Dollar Amount:$1.2 billionContract Dates:9/02 - 2011Services Provided:QA/QC Inspection: (Tunnels, Shafts, Grouting) SpecialInspection: (Electrical, Mechanical, Structural)Engineering and CADD SupportPROJECT BACKGROUNDPart of a comprehensive $1.2 billion project to reduce sewer overflows, the Willamette River Combined Sewer Overflow(CSO) Program includes two large and technically challenging projects, the West Side CSO Project completed in 2006 andthe East Side CSO on schedule <strong>for</strong> 2011 completion. The project involved intercepting existing outfalls with 14 deep slurrywall shafts and 48,000 feet of 14- and 22-foot inside diameter tunnels mined 100 feet below groundwater in highly variablesoft soils using three slurry mix shield TBMs, the first used in the United States. The deep tunnels are lined with a one-passconcrete segmental lining. The tunnel alignments pass near or under several critical, sensitive structures, including five ofthe city’s major bridges. Deep ground improvement techniques were used to provide pre-support <strong>for</strong> these structures.Significant Challenges and/or InnovationsThe client, design team, construction manager, and contractor co-located and collaborated <strong>for</strong> nine months to develop thefinal design, cost estimates, TBM procurement, and work and safety plans. This process allowed the team to use technologiesnew to the United States including slurry TBMs, jet grouting to 320 feet, 200-foot deep slurry walls, and 120-foot deep rein<strong>for</strong>cedconcrete tremie plugs. Both contractors earned OR-OSHA VPP Star status in Oregon (two of only four contractors statewide).Roles of Major ParticipantsUnder the supervision of the <strong>Construction</strong> Manager, CMTS provided QA/QC inspection and engineering support <strong>for</strong> alldisciplines on the project. Key team members Greg Colzani and Jan Babendererde served as <strong>Construction</strong> Manager and TunnelEngineer on the project as well. Halcrow and Chris Smith provided segment design and fabrication contractor support.Downtown Seattle Transit Tunnel ExpansionSeattle, WAPROJECT DETAILSClient Representative:Seattle Sound TransitTotal Dollar Amount:$95 millionContract Dates:2004- 2007Services Provided:Project <strong>Management</strong>, ConstructabilityPROJECT BACKGROUNDThe $95 million Downtown Seattle Transit Tunnel Expansion project involved the expansion of the Seattle bus tunnel toallow conversion to dual-mode transportation, including bus and light rail. The project included the renovation of theexisting bus tunnel and upgrade of all mechanical and electrical systems.Significant Challenges and/or InnovationsThis project involved significant coordination between disciplines <strong>for</strong> a major underground project with restricted accessin the urban Seattle environment.Roles of Major ParticipantsThe VOSK Group provided project management support <strong>for</strong> the project. Vic Oblas served as Project Manager and providedconstructability, construction coordination, and commissioning support .17

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99DKey Team QualificationsThe <strong>Parsons</strong> team brings together personnel with world-class tunneling CM and design-build experience, combined witha strong connection to WSDOT and its practices. Understanding the SR 99 Bored Tunnel Design-Build project, as well asunderstanding WSDOT’s processes and procedures are critical components to complementing WSDOT’s project CM team,and is highlighted in this submittal by the “added benefit icon”. Our team consists of personnel selected to respond tomeet the specific needs identified by WSDOT as well as identify additional capacityand expertise to support WSDOT in other critical areas as necessary.denotes “Added Benefit”Key Personnel: We have assembled a group of key personnel highly knowledgeable in the specific tasks and roles that havebeen identified by WSDOT in this Request <strong>for</strong> Qualifications. These individuals have demonstrated their ability from pastprojects to both technically excel in their particular area of knowledge, and possess a strong background in tunnel CM anddesign-build delivery. Several of these individuals have in-depth first-hand knowledge of the SR 99 Tunnel Design-Buildproject through their participation in our pursuit and provide WSDOT with continuity of knowledge <strong>for</strong> the per<strong>for</strong>manceof CM servicesAdded Value Personnel: As experienced CM providers, the <strong>Parsons</strong> team understands what is necessary to successfullydeliver this project. We have provided WSDOT with proposed candidates to support your CM ef<strong>for</strong>ts <strong>for</strong> all of the anticipatedwork tasks that will need to be per<strong>for</strong>med throughout the life of the project. These individuals are available to meetwhatever support WSDOT may require to supplement their own staff, or positions in the Integrated Consultant Team (ICT)to fulfill WSDOT’s obligations on this project. Many of these individuals provide the added value through their experienceworking on a WSDOT integrated team, allowing <strong>for</strong> seamless integration.Depth of Resources: We understand that construction can ‘throw you a curve ball’ that requires the unexpected assignmentof resources necessary to deal with the particular issues at hand. To ensure continuity of staff and responsiveness, we haveidentified additional personnel with the requisite level of experience that provides WSDOT with a depth of resources thatcan be tapped to meet these unexpected staffing needs.Capacity to Per<strong>for</strong>m the WorkThe <strong>Parsons</strong> team is committed to fully meetthe staffing needs of WSDOT to per<strong>for</strong>m the CMServices requested. To that end we have identifiedleads <strong>for</strong> each of WSDOT’s specified requiredpersonnel and confirm each of their availabilityto deliver the project. In addition each lead hasbeen provided a depth of resources to draw uponto meet specific project needs correspondingto WSDOT’s desires and the design-builder’sactivitiesKey Team Qualifications18

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Technical Experts: This is an industry-defining and technically challenging project that pushes the limits in many of thetechnical areas <strong>for</strong> TBMs. The <strong>Parsons</strong> team has secured the participation of several technical experts selected from industryprofessionals and academia, widely considered leaders in their field, to provide WSDOT with the intellectual credentialsnecessary to evaluate innovative technical approaches that may be proposed by the Design-Builder.• Chris Smith, C.Eng, FICE - Segmental Lining Design and Inspection• Greg Orsolini, PE and Kimo Okamitsu, PE, SE - Structures• Edward Cording, PhD - Settlement Mitigation• Edmond Kay, MD - Hyperbaric InterventionsThe addition of these technical advisors will provide the <strong>Parsons</strong> team and WSDOT with access to a state-of-the-artknowledge pool as we complete a first of its kind tunnel project. The resume <strong>for</strong> Chris Smith is included in our key personnelsection. The remainder of the resumes are included in the appendix.Table D.1 lists our key personnel and added-value personnel, and demonstrates the type and extent of experience eachbrings to the team. Additional resumes of our available personnel, showing additional depth and breadth of our availableresources, are included in the appendicesTable D.1 – Key Staff* and Added Value StaffKEY TECHNICAL ELEMENTSGeg Colzani*Jon Kaneshiro, PE*Steve Minassian, PE*Doug Slakey, PE*Mark Bower, C.Eng*Jeff Lavinder, PE*Jan Babendererde*Dan Brown*Dan Weathers*Ben Fardi, PE*Alf Evers*Fermin Longcob*Gary Daniel*Chris Smith, C.Eng, FICE*Gordon Chen*Bryant Sanders*Nghia Giang*Bob Lenz, PE, CCM*Ralph Trapani, PETony Stirbys, LEGVic Oblas, PESoft ground pressurized-face TBM tunnels • • • • • • • • • • • •TBM tunnels constructed below groundwater • • • • • • • • • • • •TBM instrumentation and per<strong>for</strong>mance analysis • • • • • • • •Pre-cast gasketed segmental concrete lining systems • • • • • • • • • • • •Hyperbaric interventions <strong>for</strong> TBM maintenance/repair • • • • • • • • •Geotechnical instrumentation <strong>for</strong> structure monitoring • • • • • • • • • • •Deep ground improvement techniques • • • • • • • • • • • •Control tunnel construction-induced ground movement • • • • • • • • •Deep, below groundwater excavation • • • • • • • • • • • • •Support of major structures and facilities • • • • • • • • • • • • •Control/mitigation settlement of structures and utilities • • • • • • • • • • • •Systems integration of roadway and tunnel systems • • • • • • • • • •Schedule and claims analysis • • • • • • • • • • • •Underground safety program expertise • • • • • •Resident engineering and inspection on tunnel projects • • • • • • • • • • • • • • •VALUE ADDED SERVICE CAPABILITIESIntegrated team co-located with owner • • • • • • • • • • • • • • • •Detailed knowledge of SR 99 design-build project scope • • • • • • • •Risk analysis of SR 99 design-build project • • • • • • •Understanding of SR 99 design-build costs • • • •WSDOT experience • • • • • • • • • •Commissioning • • • • •Rhonda KolodjiJohn Donatelli, PE19

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Key Team Member QualificationsGreg ColzaniResident Engineer, <strong>Parsons</strong>highlightsBlended Client/Consultant TeamSystems IntegrationUnderground SafetySoft Ground TunnelBelow WaterHyperbaric InterventionLocal ExperienceSegmental LinerGeotech InstrumentationDesign-BuildEducationB.S., Geology, Adams StateCollegeRELEVANT PROJECT EXPERIENCEWillamette River CombinedSewer Overflow Program– West Side CSO Projectand East Side CSO Project,Portland, ORProject Owner:Paul GribbonChief Engineer, (503) 823-7747OVERVIEWOur proposed Resident Engineer, Greg Colzani, has more than 30 yearsof experience in mining, tunneling, and heavy civil and undergroundconstruction with an emphasis in quality control and constructionmanagement. His tunneling experience includes TBM excavations in variousranges of rock and soil environments, as well as the supervision of complexexcavations in soft ground conditions. Greg has written constructionspecifications and provided constructability reviews <strong>for</strong> a number ofsoft ground tunneling projects. In the roles of <strong>Construction</strong> Managerand Resident Engineer, he has provided expertise in the selection of TBMmachines as part of evaluations of contractors’ alternative proposals.Greg has comprehensive experience in a wide variety of shaft construction methods, including complex deep slurrywalls, jet grouting, ground freezing, and drilled and conventionally excavated shafts. He has filled the roles of ChiefInspector and Project Engineer <strong>for</strong> multi-lane highway tunnel systems and ventilation contracts.Greg is experienced with the development, training, and management of CM consultant staff and blended project staffteams. He has participated actively in dispute resolution boards (DRB), risk management, and partnering activities.The $1.2 billion Willamette River CSO program includes the West Side and East Side CSO tunnel projects. The WestSide CSO project was completed in 2006, and the East Side CSO project is on schedule <strong>for</strong> 2011 completion. Theproject involved intercepting existing outfalls with 14 deep slurry wall shafts and 48,000 feet of 14- and 22-footdiameter tunnels mined 100 feet below groundwater, using three slurry mix shield TBMs, the first used in theUnited States. The deep tunnels are lined with a one-pass, steel fiber rein<strong>for</strong>ced concrete segmental lining, the firstof its kind in the United States. Greg served as lead of a blended team of client and consultant staff identified toprovide overall construction management, quality assurance, work and safety planning, contract administration,and project controls <strong>for</strong> the program.South Bay Ocean OutfallContract Package No. 2,San Diego, CAProject Owner:Rolf Lee, Associate Civil Engineer,(619) 533-4660I-70 Hanging Lake Tunnels,Glenwood Springs, COProject Owner:Joe Elsen, PERegion 3 Project Engineer,(970) 384-3332The South Bay Ocean Outfall project’s major components consisted of a 200-foot-deep, concrete-lined dropshaft that used ground freezing <strong>for</strong> support; 19,000 linear feet of precast, segment-lined, 11-foot diametertunnel excavated by an earth pressure balanced TBM (EPBM) subjected up to 7 bar hydrostatic pressure; cutterreplacement was per<strong>for</strong>med under hyperbaric interventions up to 3 bar. Greg developed inspection and testingplans <strong>for</strong> quality control/quality assurance (QC/QA), and supervised the <strong>Construction</strong> Manager’s QC inspection staff.He also interfaced with city and federal agencies and citizen action groups.The Hanging Lake Tunnels project includes two, multi-lane vehicular tunnels (5,000 linear feet), ventilation, andcontrol facilities. The tunnels provide a critical link to I-70 in Colorado. Greg served as the Senior Inspector <strong>for</strong><strong>Construction</strong> of the Cinnamon Creek operations and ventilation building, including electrical, tunnel ventilation,control systems installation, and commissioning.20

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Jon Kaneshiro, PEPre-<strong>Construction</strong> Services Lead, <strong>Parsons</strong>highlightsDesign-BuildBlended Client/Consultant TeamRisk <strong>Management</strong>GeotechnicalInstrumentationLocal ExperienceEducationM.S.,Engineering Science,B.A., Geology,University of Cali<strong>for</strong>nia,BerkeleyREGISTRATIONSProfessional Engineer: WA,CA, CO, OR, TXRELEVANT PROJECT EXPERIENCEI-25 T-REX Design-Build,Denver, COProject Owner:Matthew A. GreerStructural and HydraulicsEngineer, (720) 963-3008OVERVIEWOur proposed Pre-<strong>Construction</strong> Lead, Jon Kaneshiro, has 30 years of designmanagement experience in planning, construction, and the seismic analysisof tunnels, foundations, mass excavations, and underground projects. Hisexpertise in tunnel engineering includes over 150 tunnels, 45 of which heserved as Engineer of Record. As the Design Manager on more than 20contracts, Jon’s experience incorporates the final design of unique one-pass,bolted, gasketed segmental liners. Jon’s understanding of the design andconstruction challenges of soft ground tunneling, liquefaction, fault crossing design, and the final design of deep excavationsand tiebacks includes local knowledge from preliminary engineering, methodology studies, and design reviews in Seattle - theBeacon Hill tunnels, the Metro Downtown Seattle Transit (Bus Tunnel) project, and the Sound Transit Design-Build of theCentral Link Extension Tunnels.An important feature of this $2 billion multi-modal transportation reconstruction design-build project was the3,000-foot-long new outfall, consisting of a 15-foot diameter by 1,800-foot-long EPBM tunnel, and a 10-foot-diameterby 300-foot-long EPBM tunnel in soft ground. The innovative design solution reduced the alignment length by one-third,avoided right-of-way costs, and avoided a hazardous waste-laden route. This was the first one-pass gasketed, segmentedliner used in the United States with all dowel and rod fastening elements. Jon provided design management and detaileddesign and construction services <strong>for</strong> all of the underground work. His role extended through to the construction phase.Capital ImprovementProjects <strong>for</strong> SouthernNevada WaterAuthority, Las Vegas, NVProject Owner:Marc JensenDirector of Engineering(702) 862-3400South Bay Tunnel andOcean Outfall,San Diego, CAProject Owner:Anne SasakiAssistant Director at City ofSan Diego, Public UtilitiesDepartment,(858) 292-6469<strong>Parsons</strong> is providing program management services <strong>for</strong> $1.5 billion of capital improvement projects <strong>for</strong> the SouthernNevada Water Authority, including an evaluation of several long tunnels, pipelines, canals, and dam sites. The 20-footinterior diameter, one-pass, bolted, gasketed, precast concrete segmented Lake Mead No. 3 shafts and tunnels are boredbelow groundwater in rock, weak rock, and soft ground, mined with an optimal variable continuous drive hybrid TBM. Jonprovided program and construction management reviews <strong>for</strong> the Lake Mead shafts and associated connecting tunnelsfrom planning, geotechnical investigation and instrumentation, and design through construction. For the Lake Mead No.3 project, he prepared concept-level studies <strong>for</strong> tunneling methods, feasibility, and cost.This $140 million project involved engineering design and construction-phase services <strong>for</strong> the planning, alignment,and design of the 19,000-foot-long by 13-foot-diameter tunnel outfall, driven through soft ground using an EPBM atdepths of up to 220 feet below sea level. The one-pass, precast concrete, gasketed segmental liner had to resist the 7-barexternal hydraulic head during excavation, and also be designed <strong>for</strong> an internal pressure differential of 3 bars. This projectreceived three national awards - the 2000 ASCE Outstanding Civil Engineering Achievement Award of Merit, the 2000APWA Environmental Project of the Year, and the 2000 AAEE Grand Prize <strong>for</strong> Design. Jon served as the Task Manager <strong>for</strong>the tunnel, drop shaft design, and geotechnical investigations, and as the Project Manager and Field Lead <strong>for</strong> the tunnels,drop shaft, and riser shaft during construction. Jon ensured all of the client’s design criteria were met.21

Steve Minassian, PECM Services Manager, <strong>Parsons</strong>highlightsSoft Ground TunnelBelow WaterLarge DiameterOne-Pass PrecastSegmental LinerDesign-BuildUnderground SafetyRisk <strong>Management</strong>EducationM.S., Civil Engineering,University of Cali<strong>for</strong>nia,BerkeleyB.S., Civil Engineering, USCREGISTRATIONSProfessional Engineer, CARELEVANT PROJECT EXPERIENCEPort of Miami Tunnel,Miami, FLProject Owner:Louis BraisProject Director(305) 798-7144Al Salam Street Tunnel,Abu Dhabi, UAEProject Owner:Abdulla Saeed Sultan AlShamsi, Acting ExecutiveDirector of Infrastructureand Municipal Assets Sector971 2 695 7476North Shore ConnectorProject / AlleghenyRiver Crossing Tunnel,Pittsburgh, PAProject Owner:Winston SimmonsDirector of <strong>Construction</strong>(412) 566-5100Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99OVERVIEWOur proposed CM Services Manager, Steve Minassian, has <strong>for</strong> the past25 years fulfilled many diverse roles serving the tunneling industry.Steve has served as the Design Manager and <strong>Construction</strong> Manager onseveral high-profile soft ground tunneling projects. Steve was theProject Manager <strong>for</strong> the Port of Miami Tunnel project, where he wastasked to lead the design-build joint venture’s design ef<strong>for</strong>ts <strong>for</strong> thelargest diameter EPBM tunnel in the United States to date. As the contractor’s Project Manager, Steve successfullydelivered two large tunnel projects on time and within budget. Each project had over one million man-hoursworked without major accidents or injuries, resulting in considerable cost returns to the owner-controlled insuranceprogram. Steve has gained valuable hands-on tunneling experience working as a contractor’s Project and FieldEngineer, where he was tasked with bid estimating, engineering planning, construction operations planning,implementation, and providing efficient, safe, and cost-effective solutions to solve day-to-day construction issues.Steve has participated actively in risk management, partnering, and dispute resolution board (DRB) proceedings.The major component of this project is the 4,000-foot-long, twin-bore, 41-foot OD underwater tunnels connecting Watsonand Dodge Islands in Miami. The tunnel will be constructed using an EPBM through fill, in situ soil, and Miami Limestone,a heterogeneous weak rock <strong>for</strong>mation with the potential of encountering Karst terrain and clean soil below groundwater.This tunnel will be the largest, one-pass, precast concrete, segmental lining tunnel in the United States. Steve servedas the Design Manager and Project Manager <strong>for</strong> the Bouygues Civil Work Florida Design-Build Joint Venture. His dutiesincluded overall design coordination, project management, tunnel design, geotechnical studies, and risk management.This $1.4 billion project is designed to double vehicle capacity and provide access <strong>for</strong> development. The project features amajor 3.1-kilometer-long, 45-meter-wide box structure, eight-lane tunnel that runs through the central business district,and a total of 1.2 kilometers of road access the tunnel. The state-of-the-art tunnel safety and management system willcoordinate ventilation, fire detection and suppression, lighting, public address, environmental management, electricalpower supply, emergency broadcasting, radio re-broadcasting, security and surveillance, traffic detection and control,and traveler in<strong>for</strong>mation. Steve served as the Special Projects Manager/Technical Advisor providing construction supportto the project management/CM team. Steve’s duties included construction scheduling/sequencing/interface supportbetween the owner/design-builder and the CM, as well as providing technical construction phasing expertise.The 1.1 miles of twin-bored tunnel with a 20-foot interior diameter and an 11-inch thick one-pass, precast segmentallining was constructed using a slurry shield TBM in soft ground and soft rock conditions. <strong>Construction</strong> challengesincluded mixed-face tunneling, tunneling under the Allegheny River, tunneling within 10 feet of existing multi-storybuildings, and working (<strong>for</strong> stations) in the well-developed city center of Pittsburgh. As the <strong>Construction</strong> Manager <strong>for</strong> theproject, Steve provided day-to-day management of CM operations, monitoring of construction, QA, change and claimsmanagement, and risk management. Steve also provided constructability reviews and participated actively in partneringand DRB proceedings.22

Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesSR 99Doug Slakey, PETunnel Systems Integrator, <strong>Parsons</strong>highlightsSystems IntegrationBlended Client/Consultant TeamProject KnowledgeEducationM.S., Civil Engineering, MITB.S., Engineering, HarveyMudd CollegeREGISTRATIONSProfessional Engineer: WA,CA, AKRELEVANT PROJECT EXPERIENCECaldecott TunnelImprovement Program,Contra Costa andAlameda Counties, CAProject Owner:Christina Ferraz, PECaltrans Project Manager(510) 286-3890OVERVIEWDoug Slakey has more than 28 years of experience in the planning,engineering, design, and management of civil infrastructure projects, withover 15 years of his professional practice spent in the planning, design,and construction of highway tunnel systems, communications systemarchitecture, and ITS. His project experience includes highway, railroad,and mass transit tunnels; railroad, urban transit, and rural highways;and bridges. Doug was responsible <strong>for</strong> the systems integration <strong>for</strong> the I-70Hanging Lake Tunnels in Colorado, which included a semi-transverse ventilation system with vane axial fans and a completetraffic monitoring and control system. He is presently acting as Systems Integration Lead <strong>for</strong> the Caldecott Tunnel ImprovementProgram, currently under construction on SR 24 in the hills above Oakland, CA.This project involves constructing a fourth bore through the Berkeley Hills near San Francisco. Tunnel systems <strong>for</strong> thisproject include a longitudinal ventilation system; tunnel fire detection systems, including linear heat detectors andCO monitors; redundant power supply systems, including dual power feeds, uninterrupted power supplies (UPS), anddiesel generators; tunnel lighting; supervisory control and data acquisition (SCADA) systems; emergency call boxes;and a traffic operations system (TOS) that included closed circuit television (CCTV) camera coverage, traffic signs andsignals, radio communication systems, and access control sensors. Doug managed the preliminary design and finalplans, specifications, and estimates (PS&Es) <strong>for</strong> the tunnel’s mechanical, electrical, and traffic control systems. He wasresponsible <strong>for</strong> the development of the overall tunnel operations and controls plan. Doug coordinated the overall systemsdesign and operator interface, and is providing oversight <strong>for</strong> the systems integration and acceptance testing.Glenwood CanyonTunnels,Glenwood Springs, COProject Owner:Joe Elsen, PERegion 3 Program Engineer(970) 384-3332Los Angeles CountyTraffic OperationsSystem, Los Angeles, CAProject Owner:Greg Damico, PECaltrans Project Manager(213) 897-9047This project involved providing preliminary engineering services, final design, and CM <strong>for</strong> a multimillion-dollar tunnelingef<strong>for</strong>t through the scenic and environmentally sensitive Glenwood Canyon area on I-70 in western Colorado. As part of a12-mile, four-lane final link on I-70, the project consisted of three elements - a 3,625-foot-long exploratory tunnel; thetwo-lane, twin-bore, 4,000-foot-long Hanging Lake Tunnel; and the 640-foot-long Reverse Curve Tunnel. Doug ensuredthat the systems requirements <strong>for</strong> fire life safety were in accordance with NFPA 502 and developed the emergencyresponse plan. He managed the team of mechanical, electrical, traffic, and systems design specialists <strong>for</strong> preparationof PS&Es <strong>for</strong> the integration of tunnel systems. During construction, Doug provided overall management <strong>for</strong> the systemsinstallation inspection team, per<strong>for</strong>med systems factory inspections, and supported systems integrated start-up testing andcommissioning.<strong>Parsons</strong> provided planning and final design services <strong>for</strong> the traffic monitoring and control system <strong>for</strong> five individualfreeways in the Los Angeles County area. This network was an element of the Caltrans District 7 TOS network, providingregional traffic monitoring and control through a high-speed, fiber optic communications system to provide a robust,fault-tolerant communication network. Doug managed 10 PS&E packages <strong>for</strong> the traffic communications, monitoring,and control systems on three freeways. Doug prepared site surveys <strong>for</strong> new and existing utilities and plans in accordancewith Caltrans’ standards. He also integrated the TOS elements, including CCTV cameras, variable message signs, weighin-motionsystems, traffic detector stations, and a communication data network.23

Mark Bower, C.EngTunnel Chief Inspector, HalcrowhighlightsSoft GroundPressurized FaceTBMRisk <strong>Management</strong>Precast ConcreteSegmental LiningInstallationEducationHND Civil Engineering,Portsmouth PolytechnicRegistrationsCertified Engineer, UKRELEVANT PROJECT EXPERIENCEThames Tideway & LeeTunnels, London, UKProject Owner:Phil StrideHead of London TidewayTunnels(020) 3147 7718DL Woolwich ArsenalExtension,Woolwich, UKProject Owner:Harvey PownallProject Director <strong>for</strong>Semperian(44) 208 331 4080Channel Tunnel Rail LinkSection 2, London, UKProject Owner:Paul ChapmanManaging Director(44) 207 391 4300Bored Tunnel Alternative Design-Build ProjectDesign-Build <strong>Construction</strong> <strong>Management</strong> ServicesOVERVIEWMark Bower is a Senior Technician with over 25 years of post-educationalexperience in tunneling <strong>for</strong> both water and transportation projects. Hismain responsibilities include project management and site supervision inthe tunneling sector, including inspection of large diameter tunnels.SR 99Mark’s tunnel program experience includes program management,health and safety reviews, quality management, and liaising with thirdparties. Mark has experience in construction processes <strong>for</strong> a number ofdifferent disciplines including large diameter tunnels below water using an EPBM, one-pass segmental lining, underpinnedand caisson shafts, sprayed concrete-lined (SCL) tunnels and shafts, diaphragm wells, cast-in-situ and driven piling, precastconcrete manufacturing, structural waterproofing, settlement monitoring, grouting, ground stabilization, and railway P-wayinstallation.The $800 million Lee Tunnel contract involves the construction of a 7.2-meter diameter, 6.9-kilometer-long sewagestorage and transfer tunnel between the Abbey Mills Pumping Station and the Beckton Sewage Treatment Works. Thisproject includes the construction of four deep diaphragm wall shafts (max. depth 100 meters) associated with boththe installation and extraction of the TBM and the installation of mechanical, electrical, instrumentation, controls, andautomation (MEICA) equipment to operate the transfer scheme. Mark is carrying out site inspections of constructionprogress and safety standards, participating in site progress meetings and progress report monitoring as part of theproject QC <strong>for</strong> the initial construction phase of this project. He has also carried out site suitability reviews and providedsite layout schemes <strong>for</strong> the proposed drive and reception shafts.This $288 million project is comprised of a 3.6-kilometer, 5.3-meter internal diameter bored tunnel (through thanetsand and chalk) using an EPBM; a 15-meter diameter main ventilation shaft (wet caisson); two cross passages and fiveventilation adits spheroidal graphite iron (SGI segmental lined); and resilient and floating trackbed construction includingassociated P-way installation and diversion of existing and construction of new sewers. Mark carried out inspectionsduring construction work, reviewed the contractor’s method statements and inspection and test plans, and participatedin monitoring review panel meetings to assess settlement during and after the tunnel drives and shaft sinking.This is a $9.2 billion project comprised of a total of 9 kilometers of EPBM bored tunnels, three SCL shafts and connectingadits (principally constructed in thanet sands and chalk). Mark provided plant inspection services <strong>for</strong> one-pass, precastsegmental concrete linings <strong>for</strong> two of the three London Tunnels contracts. As part of the field engineering team, Markcarried out and reported on random inspections of construction work, checking compliance with specifications. Inaddition, he reviewed the contractor’s method statements and inspection and test plans, produced to control the work aspart of the contractor’s self certification procedures.24