Rubber and Tire Inspection (PDF, 1.87 MB) - Micro-Epsilon

Rubber and Tire Inspection (PDF, 1.87 MB) - Micro-Epsilon

Rubber and Tire Inspection (PDF, 1.87 MB) - Micro-Epsilon

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

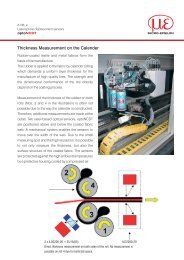

10<strong>Tire</strong> Component ProfilometerthicknessCONTROL TCP 8301.CT/CLLTInstallation sites & possible applicationsThickness profile measurement in- Extrusion lines- Innerliner calender- Ply calender- Steel cord calender- Textile or Fabric cord calenderThe systems of the thicknessCONTROL TCP8301.CT/CLLT family are developed in form ofan O-frame where the sensors are integrated inthe upper <strong>and</strong> the lower boom. They work whiletraversing <strong>and</strong> succeed through an innovativecoordinated package consisting in sensors,mechanics <strong>and</strong> software.Closed-loop temperature compensationThe systems measure differentially i.e. thethickness of the material is calculated from twodisplacement signals. Two sensors are integratedon the upper <strong>and</strong> lower boom of the O-frameon a mechanical carriage. The thickness of thetarget material is the displacement betweenthe sensors to each other <strong>and</strong> the amount ofsignals.Offering an efficient cleaning mechanism,high resistance against steam <strong>and</strong> particles isprovided. Therefore, the devices are ideal forapplications in harsh industrial environments.Furthermore, they offer efficient operation facilitiesdue to large maintenance-free intervals.Thanks to integrated in-situ calibrations whichdo not vary with temperature, they can be alsoapplied under harsh climate environmental conditionse.g. in the rubber processing industry.All sensor technologies applied measure withoutcontact, wear-free <strong>and</strong> without isotopes orX-rays. This process provides long-term reliablemeasured data while avoiding consequentialcosts.Using a patented closed-loop concept forcompensation of temperature driven parasiticeffects on the mechanics, the thicknessCON-TROL TCP 8301.CT <strong>and</strong> thicknessCONTROLTCP 8301.CLLT present a revolutionary stabilityin the production.thickness measurement with TCP 8301.TCombination profile8301.CT; vertical cursors showthe points which are used for calender control