Rubber and Tire Inspection (PDF, 1.87 MB) - Micro-Epsilon

Rubber and Tire Inspection (PDF, 1.87 MB) - Micro-Epsilon

Rubber and Tire Inspection (PDF, 1.87 MB) - Micro-Epsilon

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

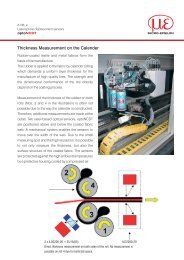

12<strong>Tire</strong> Component ProfilometerthicknessCONTROL TCP 8301.IInstallation sites & possible applicationsThickness <strong>and</strong> width profile measurement in- Extrusion lines- Innerliner calender- Ply calender- Steel cord calender- Textile or Fabric cord calender- Cap stripe lineThe non-traversing profilometers of the thicknessCONTROLTCP 8301.I series enthuse withthe complete profile measurements in one singleshot. Working nearly without moving parts thesystems provide a solution at low maintenancerequirements.Prepared for additional controlBased on the optical triangulation principle twoparallel lines are projected by laser light sourcesonto the upper <strong>and</strong> the lower side of thematerial. The reflection of the laser light is detectedby cameras.The visualization software of the profilometercontains tools for statistic processing <strong>and</strong>exporting measurement results in differentformats. The measurement system is fully covered;therefore the influence of external lighton the measurement process <strong>and</strong> the creationof parasitic reflections is minimized.Prepared for additional integration of the lengthinspection dimensionCONTROL TLI 8303.I <strong>and</strong>the dimensionCONTROL TPI 8302.C.TT, theprofilo meter is the efficient base for a completequality control of an extrusion line.The measurement system contains fully automatedintegrated calibrations. The patentedprocess of the calibration takes approximately5 minutes.Integration:PWI 8302.C-TTTLI 8303.ITCP 8301.IProfile shape modeCross profile