PT-36 Mechanized Plasmarc Cutting Torch Instruction Manual

PT-36 Mechanized Plasmarc Cutting Torch Instruction Manual

PT-36 Mechanized Plasmarc Cutting Torch Instruction Manual

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

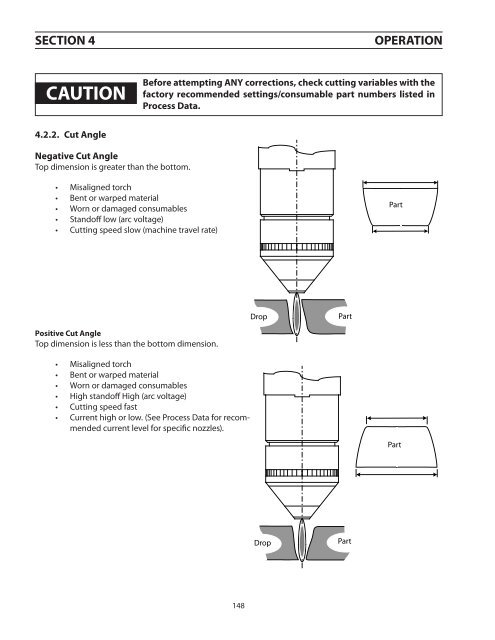

section 4operationcautionBefore attempting ANY corrections, check cutting variables with thefactory recommended settings/consumable part numbers listed inProcess Data.4.2.2. Cut AngleNegative Cut AngleTop dimension is greater than the bottom.•••••Misaligned torchBent or warped materialWorn or damaged consumablesStandoff low (arc voltage)<strong>Cutting</strong> speed slow (machine travel rate)PartDropPartPositive Cut AngleTop dimension is less than the bottom dimension.••••••Misaligned torchBent or warped materialWorn or damaged consumablesHigh standoff High (arc voltage)<strong>Cutting</strong> speed fastCurrent high or low. (See Process Data for recommendedcurrent level for specific nozzles).PartDropPart148