Rex Linkbelt Roller Chain Catalog - Norfolkbearings.com

Rex Linkbelt Roller Chain Catalog - Norfolkbearings.com

Rex Linkbelt Roller Chain Catalog - Norfolkbearings.com

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

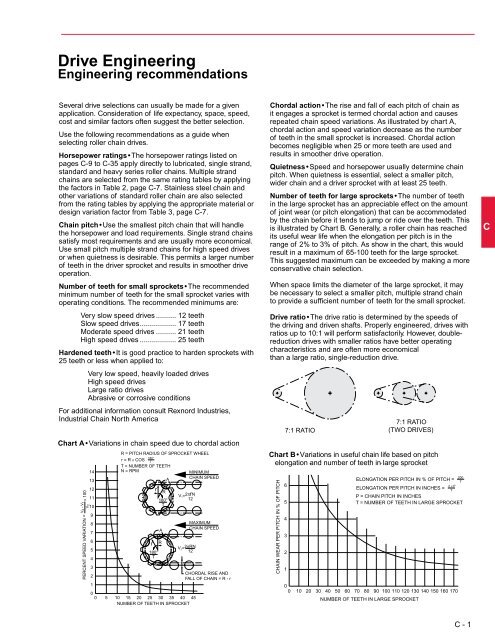

Drive EngineeringEngineering re<strong>com</strong>mendationsSeveral drive selections can usually be made for a givenapplication. Consideration of life expectancy, space, speed,cost and similar factors often suggest the better selection.Use the following re<strong>com</strong>mendations as a guide whenselecting roller chain drives.Horsepower ratings • The horsepower ratings listed onpages C-9 to C-35 apply directly to lubricated, single strand,standard and heavy series roller chains. Multiple strandchains are selected from the same rating tables by applyingthe factors in Table 2, page C-7. Stainless steel chain andother variations of standard roller chain are also selectedfrom the rating tables by applying the appropriate material ordesign variation factor from Table 3, page C-7.<strong>Chain</strong> pitch • Use the smallest pitch chain that will handlethe horsepower and load requirements. Single strand chainssatisfy most requirements and are usually more economical.Use small pitch multiple strand chains for high speed drivesor when quietness is desirable. This permits a larger numberof teeth in the driver sprocket and results in smoother driveoperation.Number of teeth for small sprockets • The re<strong>com</strong>mendedminimum number of teeth for the small sprocket varies withoperating conditions. The re<strong>com</strong>mended minimums are:Very slow speed drives........... 12 teethSlow speed drives.................. 17 teethModerate speed drives........... 21 teethHigh speed drives................... 25 teethHardened teeth • It is good practice to harden sprockets with25 teeth or less when applied to:Very low speed, heavily loaded drivesHigh speed drivesLarge ratio drivesAbrasive or corrosive conditionsFor additional information consult <strong>Rex</strong>nord Industries,Industrial <strong>Chain</strong> Chart North A : Variations America in chain speed due to chordal actionChart A : Variations in chain speed due to chordal actionV 2 - VPERCENT SPEED VARIATION = V 2 - 1 V 1 X 100 X 100V2 V2 V2R = PITCH RADIUS OF SPROCKET WHEELChart A : Variations in chain speed due to chordal actionR r = R XPITCH COS RADIUS 180°T OF SPROCKET WHEELTr =RNUMBERX COS 180° OF TEETHR = PITCH RADIUS T14N = RPM OF SPROCKET WHEELr = T R NUMBERX COS 180° OF TEETHMINIMUMTN = RPMCHAIN SPEED14 13T = NUMBER OF TEETHA MINIMUM14N = RPMMINIMUM CHAIN SPEED13 12A rA R CHAIN SPEED1312Vr1 =112πrN180°12Rr RV111= 2πrN V 1 = 2πrN1211 10T180° 12180° 1210T910T98MAXIMUMCHAIN SPEED8A7MAXIMUM MAXIMUMCHAIN CHAIN SPEED SPEEDA A76r R65r RV 2 = 2πRN180° r RV 2= 2πRN5180°12 V 2 = 2πRN124T12T180°43T3CHORDAL RISE AND32CHORDAL RISE AND2FALL OF CHAIN = R - rFALL CHORDAL OF CHAIN = RISE R - r AND211FALL OF CHAIN = R - r10055101015152020252530303535404045450NUMBER NUMBER OF OF TEETH TEETH IN SPROCKET IN SPROCKET0 5 10 15 20 25 30 35 40 45NUMBER OF TEETH IN SPROCKETChart A • Variations in chain speed due to chordal actionPERCENT SPEED VARIATION = V 2 - V 1 X 100CHAIN WEAR PER PITCH IN % OF PITCH7:1 RATIO7:1 RATIO(TWO 7:1 RATIO DRIVES)7:1 RATIO(TWO DRIVES)7:1 RATIOFig. 64607:1 RATIO(TWO DRIVES)Fig. 6460Chart B Chart • B : Variations in in useful chain life based life based on pitch Fig. on 6460 pitchelongation and number of teeth in large sprocketelongation Chart B and : Variations in useful chain life in based large on sprocketpitchChart B : Variations elongation in useful and chain number life of based teeth on in pitch large sprocketelongation and number of teeth in large sprocketELONGATION PER PITCH IN % OF PITCH = 200T6ELONGATION PER PITCH IN % INCHES OF PITCH = 2 = X P 2006ELONGATION PER PITCH IN % OF PITCH = 200T TT6ELONGATION P = CHAIN PITCH PER IN PITCH INCHESINCHES = 2 X PELONGATION PER PITCH IN INCHES = 2 X PT5T = NUMBER OF TEETH IN T LARGE SPROCKETP CHAIN PITCH IN INCHESP = CHAIN PITCH IN INCHES55T = NUMBERTOF= NUMBERTEETH IN LARGEOF TEETHSPROCKETIN LARGE SPROCKET4432100Chordal action • The rise and fall of each pitch of chain asit engages a sprocket is termed chordal action and causesrepeated chain speed variations. As illustrated by chart A,chordal action and speed variation decrease as the numberof teeth in the small sprocket is increased. Chordal actionbe<strong>com</strong>es negligible when 25 or more teeth are used andresults in smoother drive operation.Quietness • Speed and horsepower usually determine chainpitch. When quietness is essential, select a smaller pitch,wider chain and a driver sprocket with at least 25 teeth.Number of teeth for large sprockets • The number of teethin the large sprocket has an appreciable effect on the amountof joint wear (or pitch elongation) that can be ac<strong>com</strong>modatedby the chain before it tends to jump or ride over the teeth. Thisis illustrated by Chart B. Generally, a roller chain has reachedits useful wear life when the elongation per pitch is in therange of 2% to 3% of pitch. As show in the chart, this wouldresult in a maximum of 65-100 teeth for the large sprocket.This suggested maximum can be exceeded by making a moreconservative chain selection.When space limits the diameter of the large sprocket, it maybe necessary to select a smaller pitch, multiple strand chainto provide a sufficient number of teeth for the small sprocket.Drive ratio • The drive ratio is determined by the speeds ofthe driving and driven shafts. Properly engineered, drives withratios up to 10:1 will perform satisfactorily. However, doublereductiondrives with smaller ratios have better operatingcharacteristics and are often more economicalthan a large ratio, single-reduction drive.CHAIN CHAIN WEAR WEAR PER PER PITCH PITCH IN % IN OF % PITCH OF PITCH433221100 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 17010 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 17000 10 NUMBER 20 30 OF NUMBER TEETH 40 50IN OF 60 LARGE TEETH 70 SPROCKET 80IN 90 LARGE 100 110 SPROCKET 120 130 140 150 160 170NUMBER OF TEETH IN LARGE SPROCKETFig. 7314 Fig. 7314Fig. 7314C - 1C