Rex Linkbelt Roller Chain Catalog - Norfolkbearings.com

Rex Linkbelt Roller Chain Catalog - Norfolkbearings.com

Rex Linkbelt Roller Chain Catalog - Norfolkbearings.com

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

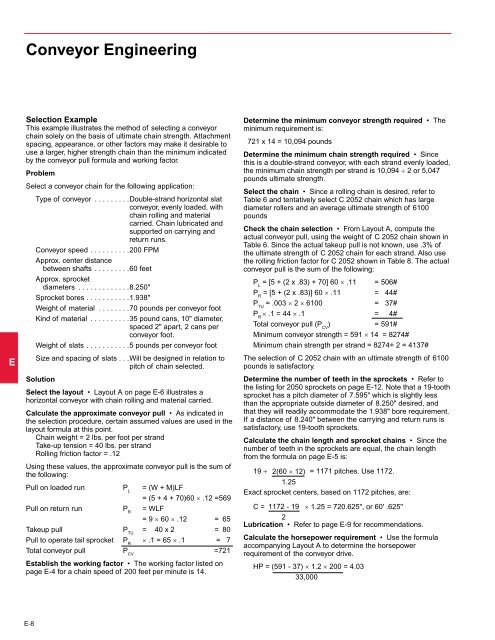

Conveyor EngineeringESelection ExampleThis example illustrates the method of selecting a conveyorchain solely on the basis of ultimate chain strength. Attachmentspacing, appearance, or other factors may make it desirable touse a larger, higher strength chain than the minimum indicatedby the conveyor pull formula and working factor.ProblemSelect a conveyor chain for the following application:Type of conveyor . . . . . . . . .Double-strand horizontal slatconveyor, evenly loaded, withchain rolling and materialcarried. <strong>Chain</strong> lubricated andsupported on carrying andreturn runs.Conveyor speed . . . . . . . . . .200 FPMApprox. center distancebetween shafts . . . . . . . . .60 feetApprox. sprocketdiameters . . . . . . . . . . . . .8.250"Sprocket bores . . . . . . . . . . .1.938"Weight of material . . . . . . . .70 pounds per conveyor footKind of material . . . . . . . . . .35 pound cans, 10" diameter,spaced 2" apart, 2 cans perconveyor foot.Weight of slats . . . . . . . . . . .5 pounds per conveyor footSize and spacing of slats . . .Will be designed in relation topitch of chain selected.SolutionSelect the layout • Layout A on page E-6 illustrates ahorizontal conveyor with chain rolling and material carried.Calculate the approximate conveyor pull • As indicated inthe selection procedure, certain assumed values are used in thelayout formula at this point.<strong>Chain</strong> weight = 2 lbs. per foot per strandTake-up tension = 40 lbs. per strandRolling friction factor = .12Using these values, the approximate conveyor pull is the sum ofthe following:Pull on loaded run P L= (W + M)LF= (5 + 4 + 70)60 × .12 =569Pull on return run P R= WLF= 9 × 60 × .12 = 65Takeup pull P TU= 40 x 2 = 80Pull to operate tail sprocket P R× .1 = 65 × .1 = 7Total conveyor pull P CV=721Establish the working factor • The working factor listed onpage E-4 for a chain speed of 200 feet per minute is 14.Determine the minimum conveyor strength required • Theminimum requirement is:721 x 14 = 10,094 poundsDetermine the minimum chain strength required • Sincethis is a double-strand conveyor, with each strand evenly loaded,the minimum chain strength per strand is 10,094 ÷ 2 or 5,047pounds ultimate strength.Select the chain • Since a rolling chain is desired, refer toTable 6 and tentatively select C 2052 chain which has largediameter rollers and an average ultimate strength of 6100poundsCheck the chain selection • From Layout A, <strong>com</strong>pute theactual conveyor pull, using the weight of C 2052 chain shown inTable 6. Since the actual takeup pull is not known, use .3% ofthe ultimate strength of C 2052 chain for each strand. Also usethe rolling friction factor for C 2052 shown in Table 8. The actualconveyor pull is the sum of the following:P L= [5 + (2 x .83) + 70] 60 × .11 = 506#P R= [5 + (2 x .83)] 60 × .11 = 44#P TU= .003 × 2 × 6100 = 37#P R× .1 = 44 × .1 = 4#Total conveyor pull (P CV) = 591#Minimum conveyor strength = 591 × 14 = 8274#Minimum chain strength per strand = 8274÷ 2 = 4137#The selection of C 2052 chain with an ultimate strength of 6100pounds is satisfactory.Determine the number of teeth in the sprockets • Refer tothe listing for 2050 sprockets on page E-12. Note that a 19-toothsprocket has a pitch diameter of 7.595" which is slightly lessthan the appropriate outside diameter of 8.250" desired, andthat they will readily ac<strong>com</strong>modate the 1.938" bore requirement.If a distance of 8.240" between the carrying and return runs issatisfactory, use 19-tooth sprockets.Calculate the chain length and sprocket chains • Since thenumber of teeth in the sprockets are equal, the chain lengthfrom the formula on page E-5 is:19 + 2(60 × 12) = 1171 pitches. Use 1172.1.25Exact sprocket centers, based on 1172 pitches, are:C = 1172 - 19 × 1.25 = 720.625", or 60' .625"2Lubrication • Refer to page E-9 for re<strong>com</strong>mendations.Calculate the horsepower requirement • Use the formulaac<strong>com</strong>panying Layout A to determine the horsepowerrequirement of the conveyor drive.HP = (591 - 37) × 1.2 × 200 = 4.0333,000E-8