Abstracts of the Academy of Dental Materials Annual ... - IsiRed

Abstracts of the Academy of Dental Materials Annual ... - IsiRed

Abstracts of the Academy of Dental Materials Annual ... - IsiRed

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

all three oxide ceramics (28.4 ± 3.3 MPa to 32.7 ± 3.4 MPa) was<br />

significantly higher (p ≤ 0.05) than to <strong>the</strong> non-coated groups<br />

AS and APA (9.0 ± 1.8 MPa to 19.6 ± 2.2 MPa). In contrast to<br />

some <strong>of</strong> <strong>the</strong> AS and APA groups <strong>the</strong>rmocycling had no significant<br />

effect (p ≤ 0.05) on resin-bond strength to <strong>the</strong> coated<br />

groups.<br />

Conclusions: The bond strength <strong>of</strong> self-adhesive resin<br />

cement containing 4-META to Y-TZP, Al2O3 and In-Ceram<br />

Zirconia ceramics can be improved by <strong>the</strong> surface functionalization<br />

<strong>of</strong> oxide ceramics with a nano-structured alumina<br />

coating. Fur<strong>the</strong>rmore, bond strength to coated oxide ceramic<br />

surfaces is resistant to degradation by <strong>the</strong>rmocycling.<br />

doi:10.1016/j.dental.2010.08.119<br />

112<br />

Effect <strong>of</strong> tooth preparation on <strong>the</strong> fit <strong>of</strong> Y-TZP copings<br />

R.I. Hmaidouch, P.E. Neumann, W.-D. Mueller<br />

“Charité” Universitaetsmedizin Berlin, CC3 <strong>Dental</strong> School, Berlin,<br />

Germany<br />

Objectives: This study evaluated marginal and internal<br />

adaptation <strong>of</strong> Cerec3 copings using two occlusal preparation<br />

forms.<br />

<strong>Materials</strong> and methods: Two metal master models (tooth<br />

36: A, normal occlusal reduction; B, flat occlusal reduction)<br />

were used. 80 gypsum dies were produced from<br />

each master model. 16 groups were established by combining<br />

<strong>the</strong> two preparation forms with two luting space<br />

settings/ LSS (100 and 50 �m) and four cements (zinc phosphate/ZPC,<br />

Panavia21/p21, experimental cement.1/Exp.1 and<br />

Exp.2). 80 copings were milled using Y-TZP 1 ceramic, 5<br />

pieces for each group. Copings were cemented, embedded<br />

and <strong>the</strong>n sectioned bucco-lingually and mesio-distally.<br />

Marginal gaps (MG) and internal gaps (IG) were measured<br />

using a light microscope at 40×, 82 measurements for each<br />

coping.<br />

Results: One-way ANOVA (P < 0.05) showed significant difference<br />

between copings with normal occlusal form and<br />

copings with flat occlusal form, between copings with LSS<br />

<strong>of</strong> 100 �m and those with LSS <strong>of</strong> 50 �m. Also between copings<br />

cemented with P21 and <strong>the</strong> o<strong>the</strong>r cements. Results are<br />

summarized in Table 1:<br />

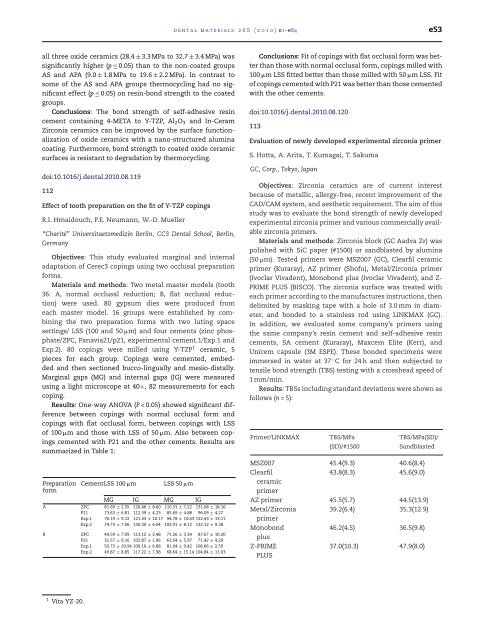

Preparation<br />

form<br />

CementLSS 100 �m LSS 50 �m<br />

MG IG MG IG<br />

A ZPC 81.69 ± 2.55 120.46 ± 8.60 110.31 ± 7.22 131.68 ± 18.16<br />

P21 73.63 ± 6.81 112.39 ± 4.23 85.69 ± 4.88 96.09 ± 4.27<br />

Exp.1 76.19 ± 9.12 121.43 ± 10.17 94.78 ± 14.63 122.43 ± 13.11<br />

Exp.2 74.73 ± 7.06 130.30 ± 6.04 103.91 ± 8.12 132.12 ± 9.28<br />

B ZPC 44.59 ± 7.09 113.12 ± 2.48 71.26 ± 3.34 87.67 ± 10.20<br />

P21 31.57 ± 9.16 102.87 ± 1.96 61.54 ± 5.97 71.42 ± 4.29<br />

Exp.1 50.73 ± 19.94 109.16 ± 6.88 81.04 ± 9.42 106.06 ± 2.59<br />

Exp.2 49.87 ± 8.85 117.22 ± 7.98 68.64 ± 15.14 104.84 ± 11.03<br />

1 Vita YZ-20.<br />

dental materials 26S (2010) e1–e84 e53<br />

Conclusions: Fit <strong>of</strong> copings with flat occlusal form was better<br />

than those with normal occlusal form, copings milled with<br />

100 �m LSS fitted better than those milled with 50 �m LSS. Fit<br />

<strong>of</strong> copings cemented with P21 was better than those cemented<br />

with <strong>the</strong> o<strong>the</strong>r cements.<br />

doi:10.1016/j.dental.2010.08.120<br />

113<br />

Evaluation <strong>of</strong> newly developed experimental zirconia primer<br />

S. Hotta, A. Arita, T. Kumagai, T. Sakuma<br />

GC, Corp., Tokyo, Japan<br />

Objectives: Zirconia ceramics are <strong>of</strong> current interest<br />

because <strong>of</strong> metallic, allergy-free, recent improvement <strong>of</strong> <strong>the</strong><br />

CAD/CAM system, and aes<strong>the</strong>tic requirement. The aim <strong>of</strong> this<br />

study was to evaluate <strong>the</strong> bond strength <strong>of</strong> newly developed<br />

experimental zirconia primer and various commercially available<br />

zirconia primers.<br />

<strong>Materials</strong> and methods: Zirconia block (GC Aadva Zr) was<br />

polished with SiC paper (#1500) or sandblasted by alumina<br />

(50 �m). Tested primers were MSZ007 (GC), Clearfil ceramic<br />

primer (Kuraray), AZ primer (Sh<strong>of</strong>u), Metal/Zirconia primer<br />

(Ivoclar Vivadent), Monobond plus (Ivoclar Vivadent), and Z-<br />

PRIME PLUS (BISCO). The zirconia surface was treated with<br />

each primer according to <strong>the</strong> manufactures instructions, <strong>the</strong>n<br />

delimited by masking tape with a hole <strong>of</strong> 3.0 mm in diameter,<br />

and bonded to a stainless rod using LINKMAX (GC).<br />

In addition, we evaluated some company’s primers using<br />

<strong>the</strong> same company’s resin cement and self-adhesive resin<br />

cements, SA cement (Kuraray), Maxcem Elite (Kerr), and<br />

Unicem capsule (3M ESPE). These bonded specimens were<br />

immersed in water at 37 ◦ C for 24 h and <strong>the</strong>n subjected to<br />

tensile bond strength (TBS) testing with a crosshead speed <strong>of</strong><br />

1 mm/min.<br />

Results: TBSs including standard deviations were shown as<br />

follows (n = 5):<br />

Primer/LINKMAX TBS/MPa<br />

(SD)/#1500<br />

TBS/MPa(SD)/<br />

Sandblasted<br />

MSZ007 45.4(9.3) 40.6(8.4)<br />

Clearfil<br />

ceramic<br />

primer<br />

43.8(8.3) 45.6(9.0)<br />

AZ primer 45.5(5.7) 44.5(13.9)<br />

Metal/Zirconia<br />

primer<br />

39.2(6.4) 35.3(12.9)<br />

Monobond<br />

plus<br />

46.2(4.5) 36.5(9.8)<br />

Z-PRIME<br />

PLUS<br />

37.0(10.3) 47.9(8.0)