EWPAA Structural Plywood and LVL Design Manual - Engineered ...

EWPAA Structural Plywood and LVL Design Manual - Engineered ...

EWPAA Structural Plywood and LVL Design Manual - Engineered ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

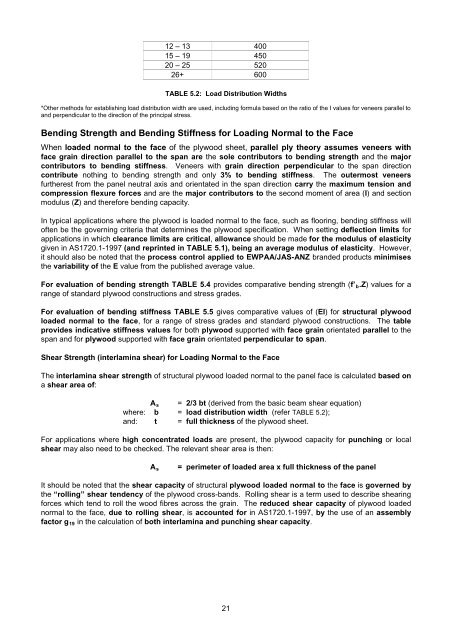

12 – 13 40015 – 19 45020 – 25 52026+ 600TABLE 5.2: Load Distribution Widths*Other methods for establishing load distribution width are used, including formula based on the ratio of the I values for veneers parallel to<strong>and</strong> perpendicular to the direction of the principal stress.Bending Strength <strong>and</strong> Bending Stiffness for Loading Normal to the FaceWhen loaded normal to the face of the plywood sheet, parallel ply theory assumes veneers withface grain direction parallel to the span are the sole contributors to bending strength <strong>and</strong> the majorcontributors to bending stiffness. Veneers with grain direction perpendicular to the span directioncontribute nothing to bending strength <strong>and</strong> only 3% to bending stiffness. The outermost veneersfurtherest from the panel neutral axis <strong>and</strong> orientated in the span direction carry the maximum tension <strong>and</strong>compression flexure forces <strong>and</strong> are the major contributors to the second moment of area (I) <strong>and</strong> sectionmodulus (Z) <strong>and</strong> therefore bending capacity.In typical applications where the plywood is loaded normal to the face, such as flooring, bending stiffness willoften be the governing criteria that determines the plywood specification. When setting deflection limits forapplications in which clearance limits are critical, allowance should be made for the modulus of elasticitygiven in AS1720.1-1997 (<strong>and</strong> reprinted in TABLE 5.1), being an average modulus of elasticity. However,it should also be noted that the process control applied to <strong>EWPAA</strong>/JAS-ANZ br<strong>and</strong>ed products minimisesthe variability of the E value from the published average value.For evaluation of bending strength TABLE 5.4 provides comparative bending strength (f’ b .Z) values for arange of st<strong>and</strong>ard plywood constructions <strong>and</strong> stress grades.For evaluation of bending stiffness TABLE 5.5 gives comparative values of (EI) for structural plywoodloaded normal to the face, for a range of stress grades <strong>and</strong> st<strong>and</strong>ard plywood constructions. The tableprovides indicative stiffness values for both plywood supported with face grain orientated parallel to thespan <strong>and</strong> for plywood supported with face grain orientated perpendicular to span.Shear Strength (interlamina shear) for Loading Normal to the FaceThe interlamina shear strength of structural plywood loaded normal to the panel face is calculated based ona shear area of:A s = 2/3 bt (derived from the basic beam shear equation)where: b = load distribution width (refer TABLE 5.2);<strong>and</strong>: t = full thickness of the plywood sheet.For applications where high concentrated loads are present, the plywood capacity for punching or localshear may also need to be checked. The relevant shear area is then:A s= perimeter of loaded area x full thickness of the panelIt should be noted that the shear capacity of structural plywood loaded normal to the face is governed bythe “rolling” shear tendency of the plywood cross-b<strong>and</strong>s. Rolling shear is a term used to describe shearingforces which tend to roll the wood fibres across the grain. The reduced shear capacity of plywood loadednormal to the face, due to rolling shear, is accounted for in AS1720.1-1997, by the use of an assemblyfactor g 19 in the calculation of both interlamina <strong>and</strong> punching shear capacity.21