Standard cylinders DNC, ISO 15552 - Allied Automation, Inc.

Standard cylinders DNC, ISO 15552 - Allied Automation, Inc.

Standard cylinders DNC, ISO 15552 - Allied Automation, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

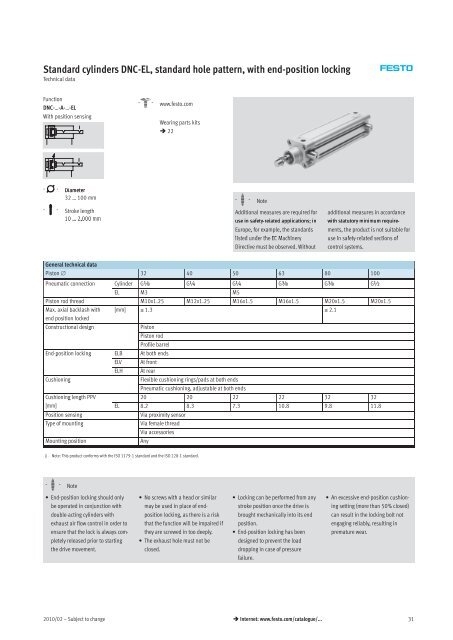

<strong>Standard</strong> <strong>cylinders</strong> <strong>DNC</strong>-EL, standard hole pattern, with end-position lockingTechnical dataFunction<strong>DNC</strong>-…-A-…-ELWith position sensing-W- www.festo.comWearing parts kits 22-N- Diameter32 … 100 mm-H- Note-T- Stroke lengthAdditional measures are required for10 … 2,000 mm use in safety-related applications; inEurope, for example, the standardslisted under the EC MachineryDirectivemustbeobserved.Withoutadditional measures in accordancewith statutory minimum requirements,the product is not suitable foruse in safety-related t sections ofcontrol systems.General technical dataPiston ∅ 32 40 50 63 80 100Pneumatic connection Cylinder Gx G¼ G¼ Gy Gy G½EL M3 M5Piston rod thread M10x1.25 M12x1.25 M16x1.5 M16x1.5 M20x1.5 M20x1.5Max. axial backlash with [mm] ≤ 1.3 ≤ 2.1end position lockedConstructional designPistonPiston rodProfile barrelEnd-position locking ELB At both endsELV At frontELH At rearCushioningFlexible cushioning rings/pads at both endsPneumatic cushioning, adjustable at both endsCushioning length PPV 20 20 22 22 32 32[mm] EL 8.2 8.3 7.3 10.8 9.8 11.8Position sensingType of mountingMounting positionVia proximity sensorVia female threadVia accessoriesAny-H- Note: This product conforms with the <strong>ISO</strong> 1179-1 standard and the <strong>ISO</strong> 228-1 standard.-H- Note• End-position locking should onlybe operated in conjunction withdouble-acting <strong>cylinders</strong> withexhaust air flow control in order toensure that the lock is always completelyreleased prior to startingthe drive movement.• No screws with a head or similarmay be used in place of endpositionlocking, as there is a riskthat the function will be impaired ifthey are screwed in too deeply.• The exhaust hole must not beclosed.• Locking can be performed from anystroke position once the drive isbrought mechanically into its endposition.• End-position locking has beendesigned to prevent the loaddropping in case of pressurefailure.• An excessive end-position cushioningsetting (more than 50% closed)canresultinthelockingboltnotengaging reliably, resulting inpremature wear.2010/02 – Subject to change Internet: www.festo.com/catalogue/...31