Type 1 1 4 - Horn USA, Inc.

Type 1 1 4 - Horn USA, Inc.

Type 1 1 4 - Horn USA, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

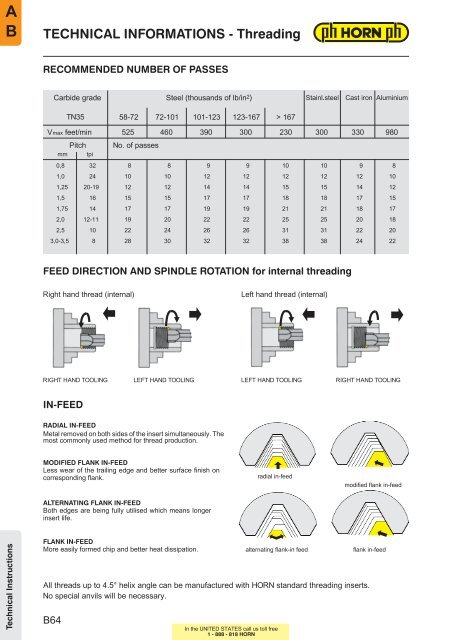

TECHNICAL INFORMATIONS − ThreadingRECOMMENDED NUMBER OF PASSESCarbide grade Steel (thousands oflb/in 2 ) Stainl.steel Cast iron AluminiumTN35 58−72 72−1 01 1 01 −1 23 1 23−1 67 > 1 67Vmaxfeet/min 525 460 390 300 230 300 330 980Pitchmm tpiNo. ofpasses0,8 32 8 8 9 9 1 0 1 0 9 81,0 24 10 10 12 12 12 12 12 101,25 20−19 12 12 14 14 15 15 14 121,5 16 15 15 17 17 18 18 17 151,75 14 17 17 19 19 21 21 18 172,0 1 2−1 1 1 9 20 22 22 25 25 20 1 82,5 10 22 24 26 26 31 31 22 203,0−3,5 8 28 30 32 32 38 38 24 22FEED DIRECTION AND SPINDLE ROTATION for internal threadingRight hand thread (internal)Left hand thread (internal)RIGHT HAND TOOLINGLEFT HAND TOOLINGLEFT HAND TOOLINGRIGHT HAND TOOLINGIN−FEEDRADIAL IN−FEEDMetal removed on both sides ofthe insertsimultaneously. Themost commonly used method for thread production.MODIFIED FLANK IN−FEEDLess wear of the trailing edge and better surface finish oncorresponding flank.radial in−feedmodified flank in−feedALTERNATING FLANK IN−FEEDBoth edges are being fully utilised which means longerinsert life.Technical InstructionsFLANK IN−FEEDMore easily formed chip and better heat dissipation.B64alternating flank−in feedIn the UNITED STATES call us toll freeflank in−feedAll threads up to 4.5˚ helix angle can be manufactured with HORN standard threading inserts.No special anvils will be necessary.