articles - Middle East Food (MEF)

articles - Middle East Food (MEF)

articles - Middle East Food (MEF)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COUNTRY / REGIONAL REPORTS UNITED KINGDOM<br />

Axium Provides Manufacturers with Cost Savings<br />

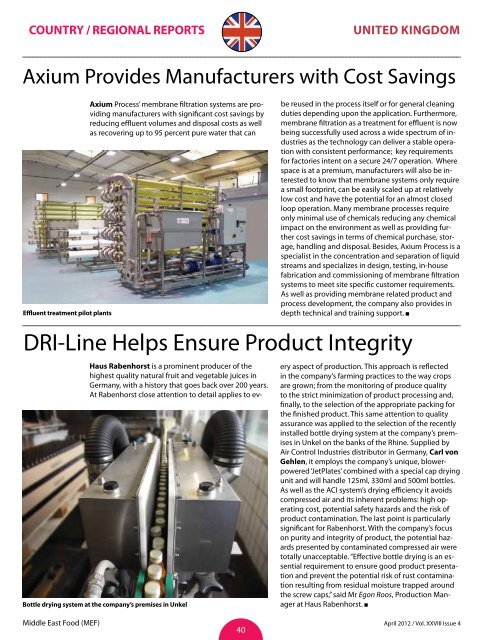

Effluent treatment pilot plants<br />

Axium Process’ membrane filtration systems are providing<br />

manufacturers with significant cost savings by<br />

reducing effluent volumes and disposal costs as well<br />

as recovering up to 95 percent pure water that can<br />

DRI-Line Helps Ensure Product Integrity<br />

Haus Rabenhorst is a prominent producer of the<br />

highest quality natural fruit and vegetable juices in<br />

Germany, with a history that goes back over 200 years.<br />

At Rabenhorst close attention to detail applies to ev-<br />

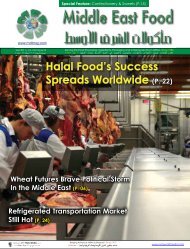

Bottle drying system at the company’s premises in Unkel<br />

be reused in the process itself or for general cleaning<br />

duties depending upon the application. Furthermore,<br />

membrane filtration as a treatment for effluent is now<br />

being successfully used across a wide spectrum of industries<br />

as the technology can deliver a stable operation<br />

with consistent performance; key requirements<br />

for factories intent on a secure 24/7 operation. Where<br />

space is at a premium, manufacturers will also be interested<br />

to know that membrane systems only require<br />

a small footprint, can be easily scaled up at relatively<br />

low cost and have the potential for an almost closed<br />

loop operation. Many membrane processes require<br />

only minimal use of chemicals reducing any chemical<br />

impact on the environment as well as providing further<br />

cost savings in terms of chemical purchase, storage,<br />

handling and disposal. Besides, Axium Process is a<br />

specialist in the concentration and separation of liquid<br />

streams and specializes in design, testing, in-house<br />

fabrication and commissioning of membrane filtration<br />

systems to meet site specific customer requirements.<br />

As well as providing membrane related product and<br />

process development, the company also provides in<br />

depth technical and training support.<br />

ery aspect of production. This approach is reflected<br />

in the company’s farming practices to the way crops<br />

are grown; from the monitoring of produce quality<br />

to the strict minimization of product processing and,<br />

finally, to the selection of the appropriate packing for<br />

the finished product. This same attention to quality<br />

assurance was applied to the selection of the recently<br />

installed bottle drying system at the company’s premises<br />

in Unkel on the banks of the Rhine. Supplied by<br />

Air Control Industries distributor in Germany, Carl von<br />

Gehlen, it employs the company’s unique, blowerpowered<br />

‘JetPlates’ combined with a special cap drying<br />

unit and will handle 125ml, 330ml and 500ml bottles.<br />

As well as the ACI system’s drying efficiency it avoids<br />

compressed air and its inherent problems: high operating<br />

cost, potential safety hazards and the risk of<br />

product contamination. The last point is particularly<br />

significant for Rabenhorst. With the company’s focus<br />

on purity and integrity of product, the potential hazards<br />

presented by contaminated compressed air were<br />

totally unacceptable. “Effective bottle drying is an essential<br />

requirement to ensure good product presentation<br />

and prevent the potential risk of rust contamination<br />

resulting from residual moisture trapped around<br />

the screw caps,” said Mr Egon Roos, Production Manager<br />

at Haus Rabenhorst.<br />

<strong>Middle</strong> <strong>East</strong> <strong>Food</strong> (<strong>MEF</strong>) April 2012 / Vol. XXVIII Issue 4<br />

40