Actuator Guide - Norgren Pneumatics. Motion Control Equipment ...

Actuator Guide - Norgren Pneumatics. Motion Control Equipment ...

Actuator Guide - Norgren Pneumatics. Motion Control Equipment ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

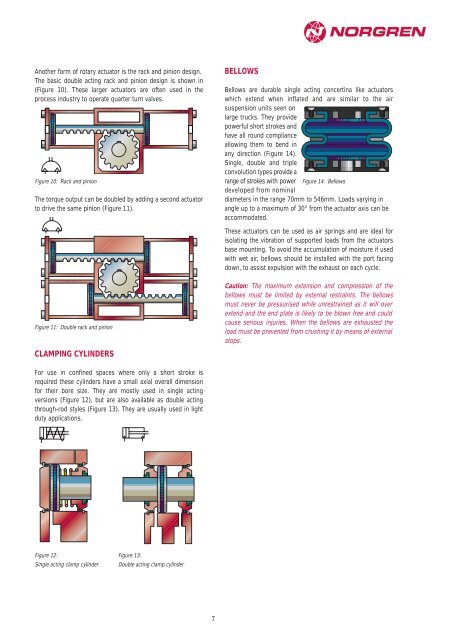

Another form of rotary actuator is the rack and pinion design.<br />

The basic double acting rack and pinion design is shown in<br />

(Figure 10). These larger actuators are often used in the<br />

process industry to operate quarter turn valves.<br />

Figure 10: Rack and pinion<br />

The torque output can be doubled by adding a second actuator<br />

to drive the same pinion (Figure 11).<br />

Figure 11: Double rack and pinion<br />

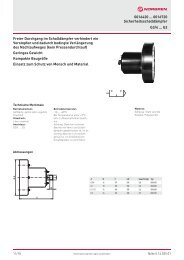

CLAMPING CYLINDERS<br />

For use in confined spaces where only a short stroke is<br />

required these cylinders have a small axial overall dimension<br />

for their bore size. They are mostly used in single acting<br />

versions (Figure 12), but are also available as double acting<br />

through-rod styles (Figure 13). They are usually used in light<br />

duty applications.<br />

Figure 12: Figure 13:<br />

Single acting clamp cylinder Double acting clamp cylinder<br />

7<br />

BELLOWS<br />

Bellows are durable single acting concertina like actuators<br />

which extend when inflated and are similar to the air<br />

suspension units seen on<br />

large trucks. They provide<br />

powerful short strokes and<br />

have all round compliance<br />

allowing them to bend in<br />

any direction (Figure 14).<br />

Single, double and triple<br />

convolution types provide a<br />

range of strokes with power Figure 14: Bellows<br />

developed from nominal<br />

diameters in the range 70mm to 546mm. Loads varying in<br />

angle up to a maximum of 30° from the actuator axis can be<br />

accommodated.<br />

These actuators can be used as air springs and are ideal for<br />

isolating the vibration of supported loads from the actuators<br />

base mounting. To avoid the accumulation of moisture if used<br />

with wet air, bellows should be installed with the port facing<br />

down, to assist expulsion with the exhaust on each cycle.<br />

Caution: The maximum extension and compression of the<br />

bellows must be limited by external restraints. The bellows<br />

must never be pressurised while unrestrained as it will over<br />

extend and the end plate is likely to be blown free and could<br />

cause serious injuries. When the bellows are exhausted the<br />

load must be prevented from crushing it by means of external<br />

stops.