PROSPECTUS THAI BEVERAGE PUBLIC COMPANY LIMITED ...

PROSPECTUS THAI BEVERAGE PUBLIC COMPANY LIMITED ...

PROSPECTUS THAI BEVERAGE PUBLIC COMPANY LIMITED ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

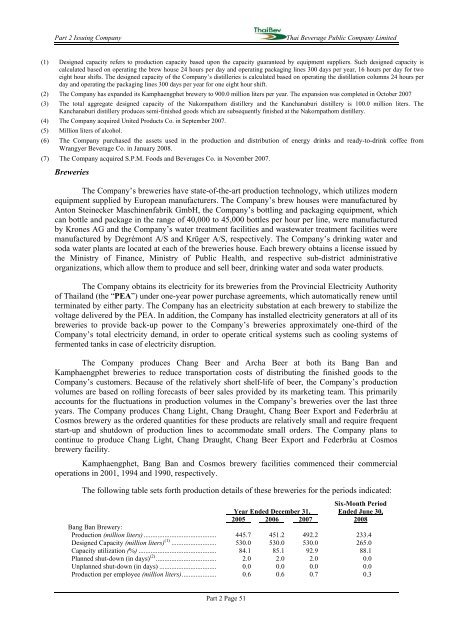

Part 2 Issuing CompanyThai Beverage Public Company Limited(1) Designed capacity refers to production capacity based upon the capacity guaranteed by equipment suppliers. Such designed capacity iscalculated based on operating the brew house 24 hours per day and operating packaging lines 300 days per year, 16 hours per day for twoeight hour shifts. The designed capacity of the Company’s distilleries is calculated based on operating the distillation columns 24 hours perday and operating the packaging lines 300 days per year for one eight hour shift.(2) The Company has expanded its Kamphaengphet brewery to 900.0 million liters per year. The expansion was completed in October 2007(3) The total aggregate designed capacity of the Nakornpathom distillery and the Kanchanaburi distillery is 100.0 million liters. TheKanchanaburi distillery produces semi-finished goods which are subsequently finished at the Nakornpathom distillery.(4) The Company acquired United Products Co. in September 2007.(5) Million liters of alcohol.(6) The Company purchased the assets used in the production and distribution of energy drinks and ready-to-drink coffee fromWrangyer Beverage Co. in January 2008.(7) The Company acquired S.P.M. Foods and Beverages Co. in November 2007.BreweriesThe Company’s breweries have state-of-the-art production technology, which utilizes modernequipment supplied by European manufacturers. The Company’s brew houses were manufactured byAnton Steinecker Maschinenfabrik GmbH, the Company’s bottling and packaging equipment, whichcan bottle and package in the range of 40,000 to 45,000 bottles per hour per line, were manufacturedby Krones AG and the Company’s water treatment facilities and wastewater treatment facilities weremanufactured by Degrémont A/S and Krüger A/S, respectively. The Company’s drinking water andsoda water plants are located at each of the breweries house. Each brewery obtains a license issued bythe Ministry of Finance, Ministry of Public Health, and respective sub-district administrativeorganizations, which allow them to produce and sell beer, drinking water and soda water products.The Company obtains its electricity for its breweries from the Provincial Electricity Authorityof Thailand (the “PEA”) under one-year power purchase agreements, which automatically renew untilterminated by either party. The Company has an electricity substation at each brewery to stabilize thevoltage delivered by the PEA. In addition, the Company has installed electricity generators at all of itsbreweries to provide back-up power to the Company’s breweries approximately one-third of theCompany’s total electricity demand, in order to operate critical systems such as cooling systems offermented tanks in case of electricity disruption.The Company produces Chang Beer and Archa Beer at both its Bang Ban andKamphaengphet breweries to reduce transportation costs of distributing the finished goods to theCompany’s customers. Because of the relatively short shelf-life of beer, the Company’s productionvolumes are based on rolling forecasts of beer sales provided by its marketing team. This primarilyaccounts for the fluctuations in production volumes in the Company’s breweries over the last threeyears. The Company produces Chang Light, Chang Draught, Chang Beer Export and Federbräu atCosmos brewery as the ordered quantities for these products are relatively small and require frequentstart-up and shutdown of production lines to accommodate small orders. The Company plans tocontinue to produce Chang Light, Chang Draught, Chang Beer Export and Federbräu at Cosmosbrewery facility.Kamphaengphet, Bang Ban and Cosmos brewery facilities commenced their commercialoperations in 2001, 1994 and 1990, respectively.The following table sets forth production details of these breweries for the periods indicated:Six-Month PeriodYear Ended December 31, Ended June 30,2005 2006 2007 2008Bang Ban Brewery:Production (million liters) .......................................... 445.7 451.2 492.2 233.4Designed Capacity (million liters) (1) .......................... 530.0 530.0 530.0 265.0Capacity utilization (%) ............................................. 84.1 85.1 92.9 88.1Planned shut-down (in days) (2) ................................... 2.0 2.0 2.0 0.0Unplanned shut-down (in days) ................................. 0.0 0.0 0.0 0.0Production per employee (million liters).................... 0.6 0.6 0.7 0.3Part 2 Page 51