MK-MK2 Rotary clamp cylinder.. - SMC Pneumatics (Ireland)

MK-MK2 Rotary clamp cylinder.. - SMC Pneumatics (Ireland)

MK-MK2 Rotary clamp cylinder.. - SMC Pneumatics (Ireland)

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

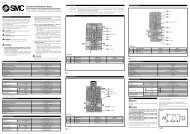

Series <strong>MK</strong>/<strong>MK</strong>2/<strong>MK</strong>2TSpecific Product Precautions 2Be sure to read this before handling.Refer to back page 1 for Safety Instructions and “Precautions for HandlingPneumatic Devices” (M-03-E3A) for Common Precautions.Operating EnvironmentWarning1. A <strong>cylinder</strong> could malfunction or the non-rotating accuracy could be affected if a rotational force isapplied to the piston rod. Therefore, observe the particulars given below before operating the<strong>cylinder</strong>.1) Make sure to mount the <strong>cylinder</strong> vertically (Fig. (3)). (<strong>MK</strong>, <strong>MK</strong>2 only)2) Do not perform any work (such as <strong>clamp</strong>ing or acting as a stopper, etc.) in the rotary direction (Fig. (4)).3) To <strong>clamp</strong>, make sure to do so within the <strong>clamp</strong> stroke (straight-line stroke) range (Fig. (5)).4) Make sure that the <strong>clamp</strong>ing surface of the workpiece is perpendicular to the <strong>cylinder</strong>'s axial line (Fig. (6)).5) Do not operate the <strong>cylinder</strong> in such a way that an external force causes the workpiece to move while being <strong>clamp</strong>ed (Fig. (7)).6) Furthermore, do not operate the <strong>cylinder</strong> in an application in which a rotational force will be applied to the piston rod.1) Do not operate the <strong>cylinder</strong> horizontally.2) Do not perform any work in the rotary direction.(<strong>MK</strong>, <strong>MK</strong>2 only)Fig. (3)Fig. (4)3) Do not <strong>clamp</strong> during the rotary stroke.<strong>Rotary</strong> stroke<strong>Rotary</strong> strokeClamp strokeFig. (5)4) Do not <strong>clamp</strong> on a slanted surface. 5) Make sure that the workpiece does not move during <strong>clamp</strong>ing.Fig. (6) Fig. (7)Back page 7