MHS(2-4) MHSL (3).pdf - SMC Pneumatics (Ireland)

MHS(2-4) MHSL (3).pdf - SMC Pneumatics (Ireland)

MHS(2-4) MHSL (3).pdf - SMC Pneumatics (Ireland)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

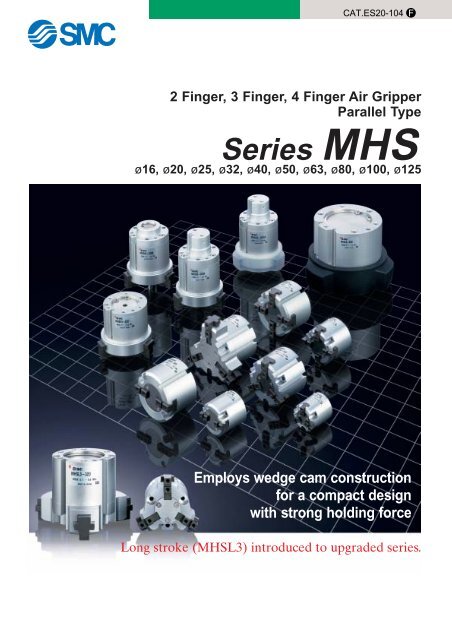

2 FingerAir GripperParallel TypeSeries <strong>MHS</strong>2ø16, ø20, ø25, ø32, ø40, ø50, ø63Cylinder Bore Sizeø16 to ø25<strong>MHS</strong> 220How to OrderDF9NNumber of fingers2 2 fingersNumber of auto switchesNil 2 pcs.S 1 pc.Cylinder Bore Sizeø32 to ø63Cylinder bore size16202516mm20mm25mmActionD Double acting<strong>MHS</strong> 250Auto switch typeNil Without auto switch (built-in magnet)Auto switch specificationsTypeAuto switch models Lead wire length (m) ∗Special Electrical Indicator Wiring Load voltageElectrical entry direction 0.5 3 5function entry light (output)DC AC Perpendicular In-line (Nil) (L) (Z)3 wire(NPN) 5V,F9NV F9N ——3 wire 12VGrommet Yes(PNP)24V —F9PV F9P —F9BV F9B —Water2 wire 12Vresistant(2 colorindicator)— F9BA — Solid state∗ Lead wire length symbols: 0.5m ....... Nil (Example) F9B3m ......... L (Example) F9BL5m ......... Z (Example) F9BZD-F9BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.DY59AApplicableloadsRelay,PLCNumber of fingers2 2 fingersNumber of auto switchesNilS2 pcs.1 pc.SymbolCylinder bore size32405063D32mm40mm50mm63mmActionDouble actingAuto switch typeNil Without auto switch (built-in magnet)Auto switch specificationsSpecial ElectricalTypeIndicator Wiring Load voltage Auto switch models Lead wire length (m) ∗ Applicablefunction entry light (output) DC AC In-line Perpendicular 0.5 (Nil) 3 (L) 5 (Z) loads3 wire (NPN)Y69A Y59A IC5V,12V—3 wire (PNP)Y7PV Y7P circuit2 wire 12V Y69B Y59B —Diagnostic3 wire (NPN)Grommet YesY7NWV Y7NW Relay,24V 5V,12V —ICindication(2 color3 wire (PNP)Y7PWV Y7PW circuit PLCindicator)Y7BWV Y7BW Waterresistant(2 color2 wire 12V— Y7BA — —indicator)Solid state∗ Lead wire length symbols: 0.5m ....... Nil (Example) Y59B3m .......... L (Example) Y59BL5m ......... Z (Example) Y59BZD-Y7BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.1

Models and SpecificationsModelCylinder bore size mmFluidOperating pressure MPaAmbient and fluid temperature °CRepeatability mmMax. operating frequency c.p.m.LubricationActionNote 1)Effective gripping forceN at pressure of0.5MPaExternalgripping forceInternalgripping forceOpening/closing stroke (both sides) mmWeight g<strong>MHS</strong>2-16D <strong>MHS</strong>2-20D <strong>MHS</strong>2-25D <strong>MHS</strong>2-32D <strong>MHS</strong>2-40D <strong>MHS</strong>2-50D <strong>MHS</strong>2-63D16 20 25 32 40 50 63212345812037424962 Finger Air Gripper Series <strong>MHS</strong>20.2 to 0.663716134Air–10 to 60±0.01Non-lubeDouble acting1111238265Note) Values for ø16 to ø25 are with gripping point L = 20mm, and for ø32 to ø63 with gripping point L = 30mm.Refer to the "Effective Gripping Force" data on pages 3 and 4 for the gripping force at each gripping position.17719583450.1 to 0.66028030612515502537169522 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3ConstructionClosed conditionOpen conditionThrough hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L3Parts listNo. Description1 Body2 Piston3 Cam4 Finger5 Cap6 End plate7 Piston boltReplacement parts/Seal kitsMaterialAluminum alloyAluminum alloyCarbon steelCarbon steelAluminum alloyStainless steelStainless steel<strong>MHS</strong>2-16D <strong>MHS</strong>2-20D <strong>MHS</strong>2-25DNoteHard anodizedHard anodizedHeat treated, Specially treatedHeat treated, Specially treatedHard anodizedNo.8910111213DescriptionRubber magnetC type snap ringPiston sealRod sealGasketGasketMaterialSynthetic rubberCarbon steelNBRNBRNBRNBRKit number<strong>MHS</strong>2-32D <strong>MHS</strong>2-40D <strong>MHS</strong>2-50D <strong>MHS</strong>2-63DNoteNickel platedContents4 finger <strong>MHS</strong>4 Auto switchesModel selection<strong>MHS</strong>16-PS <strong>MHS</strong>20-PS <strong>MHS</strong>25-PS <strong>MHS</strong>32-PS <strong>MHS</strong>40-PS <strong>MHS</strong>50-PS <strong>MHS</strong>63-PS∗ Seal kits are sets consisting of items 10, 11, 12 and 13, which can be ordered using the kit number for each cylinder bore size.A set of the aboveNos. 10, 11, 12 and 13Precautions2

Series <strong>MHS</strong>2Gripping Point• The work piece gripping point distance should be within the gripping forceranges given for each pressure in the effective gripping force graphs below.• If operated with the work piece gripping point beyond the indicated ranges, anexcessive offset load will be applied to the sliding section of the fingers, whichcan have an adverse effect on the service life of the product.Gripping pointGripping pointLExternal grippingLInternal grippingEffective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphs tothe right is expressed as F, which is the impellentforce of one finger when both of the fingers andattachments are in full contact with the work pieceas shown in the figure below.FExternal gripping force<strong>MHS</strong>2-16DGripping force N302010Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPaL: Gripping point distanceInternal gripping force<strong>MHS</strong>2-16DGripping force N30Pressure 0.6MPa0.5MPa200.4MPa0.3MPa100.2MPaF0 5 10 15 20 25 30 0 5 10 15 20 25 30Gripping point L mmGripping point L mmExternal grippingF<strong>MHS</strong>2-20D<strong>MHS</strong>2-20DGripping force N60Pressure 0.6MPa400.5MPa0.4MPaGripping force N60400.3MPa20 200.2MPaPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0 10 20 30 40 0 10 20 30 40Gripping point L mmGripping point L mmInternal grippingF1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²<strong>MHS</strong>2-25D<strong>MHS</strong>2-25DGripping force N10010080Pressure 0.6MPa0.5MPa600.4MPa400.3MPaGripping force N8060400.2MPa20 20Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0 10 20 30 40 0 10 20 30 40Gripping point L mmGripping point L mm3

Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in thegraphs to the right is expressed as F, which isthe impellent force of one finger when both ofthe fingers and attachments are in full contactwith the work piece as shown in the figurebelow.External grippingFFInternal grippingFF1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm 2Gripping force N<strong>MHS</strong>2-40D<strong>MHS</strong>2-40DGripping force N250Pressure 0.6MPa2000.5MPa15010025020015010050 0.1MPa500.1MPa0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mm<strong>MHS</strong>2-50D<strong>MHS</strong>2-50DGripping force N<strong>MHS</strong>2-63D<strong>MHS</strong>2-63DGripping force N150Pressure 0.6MPa120900.5MPa0.4MPaPressure 0.6MPa6000.5MPa2 Finger Air Gripper Series <strong>MHS</strong>2External gripping forceInternal gripping force<strong>MHS</strong>2-32D<strong>MHS</strong>2-32DGripping force NGripping force N150120900.3MPa60 600.2MPa300.1MPa300.1MPa0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mm0.4MPa0.3MPa0.2MPa400400Pressure 0.6MPaPressure 0.6MPa0 20 40 60 020 40 60Gripping point L mmGripping point L mmGripping force N300 3000.5MPaGripping force N0.4MPa200 2000.3MPa1000.2MPa1000.1MPa400 0.4MPa4000.3MPa200 0.2MPa2000.1MPaPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPaPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaPressure 0.6MPa6000.5MPa0.4MPa0.3MPa0.2MPa0.1MPa2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selection020 40 60 0 20 40 60Gripping point L mmGripping point L mmPrecautions4

24°XA, depth XBSeries <strong>MHS</strong>2Dimensions<strong>MHS</strong>2-16D to 25D2-ø3.4, counter bore dia. 6.5Counter bore depth SC (mounting hole)RA3AAABøWA, depth 1.5RAøVA, depth VBøBCB 7P(finger opening port)JKOpen EOClosed ECRBNBNARBO(Open DO)(Closed DC)QFZ20°FY20°FX2-M4 x 0.7, thread depth 8(mounting threads)4-M3 x 0.5, thread depth TBAttachment mounting threads2H9 +0.02502IGP(finger closing port)Auto switch mounting groove positions (2 locations)<strong>MHS</strong>2-16D <strong>MHS</strong>2-20D <strong>MHS</strong>2-25D556.5336324°24°554.5ø4ø4ø433°33°33°Model<strong>MHS</strong>2-16D<strong>MHS</strong>2-20D<strong>MHS</strong>2-25DAA353840AB323537B303642CB111315DC303642DO344048EC101214EO141620FX12.514.517FY111314.5FZ335G252728I455J101214K456NA81012NB05h9 -0.03006h9 -0.03006h9 -0.030O22.53PM3 x 0.5M5 x 0.8M5 x 0.8(mm)Q6785Model<strong>MHS</strong>2-16D<strong>MHS</strong>2-20D<strong>MHS</strong>2-25DRA182426RB161822SC89.510TB566VA2H92H93H9+0.0250+0.0250+0.0250VB223WA17H921H926H9+0.0430+0.0520+0.0520XA2H92H93H9+0.0250+0.0250+0.0250XB223

XA, depth XB2 Finger Air Gripper Series <strong>MHS</strong>2<strong>MHS</strong>2-32D, 40D2-øSA, counter bore dia. SBCounter bore depth 9 (mounting hole)RA3AAAB6.435°RA35°2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>35RBNAøB8øVA, depth VBRBWith dust cover<strong>MHS</strong>J34.5(Open DO)(Closed DC)Q8h9 0-0.036FZ20°FY20°FX2-UA, thread depth UB(mounting threads)øWA, depth 2Through hole<strong>MHS</strong>H34-M4 x 0.7, thread depth 8Attachment mounting threadsCBCAM5 x 0.8(finger opening port)Long stroke<strong>MHS</strong>L3Model<strong>MHS</strong>2-32D<strong>MHS</strong>2-40DModel<strong>MHS</strong>2-32D<strong>MHS</strong>2-40DAA4447SB89.5AB4144B5662UAM5 x 0.8M6 x 1CA89UB1012JOpen EOClosed EC9LCB1617VA3H94H9+0.0250+0.03002DC5662VB34DO6470IWA34H942H9EC1620+0.0620+0.0620GEO2428XA3H94H9+0.0250+0.0300FX2326.5M5 x 0.8(finger closing port)FY20.523.5XB34FZ56G30.532I67J2021L2H93H9+0.0250+0.0250NA1416Q1112RA3844RB2528(mm)SA4.55.54 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions6

XA, depth XBYCDimensions<strong>MHS</strong>2-50D, 63D4-ø5.1, counter bore dia. 9.5Counter bore depth SC (mounting hole)AARARAACAB6.435°35°5øVA, depth VBøBCBM5 x 0.8(finger opening port)JLKOpen EOClosed ECNBRBNARBO(Open DO)(Closed DC)QFZFY20°20°FX4-M6 x 1, thread depth 12(mounting threads)øWA, depth WB4-M5 x 0.8, thread depth 10Attachment mounting threadsCAIGM5 x 0.8(finger closing port)MModel<strong>MHS</strong>2-50D<strong>MHS</strong>2-63DAA5566AB5262AC34B7086CA912CB2022DC7086DO82102EC2230EO3446FX3138FY2834.5FZ67G37.544I911J2428K1011L4H96H9+0.0300+0.0300M23NA1824(mm)NB010h9 -0.036012h9 -0.043Model<strong>MHS</strong>2-50D<strong>MHS</strong>2-63DO55.5Q1417RA5266RB3438SC1214VA4H95H9+0.0300+0.0300VB45WA52H965H9+0.0740+0.0740WB22.5XA4H95H9+0.0300+0.0300XB45YC77.57

3 FingerAir GripperParallel TypeCylinder Bore Sizeø16 to ø25Cylinder Bore Sizeø32 to ø125Symbol<strong>MHS</strong> 3Number of fingers3 3 fingersCylinder bore sizeD162025Number of fingers3 3 fingersCylinder bore size3240506380100125Series <strong>MHS</strong>3ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80, ø100, ø12516mm20mm25mm<strong>MHS</strong> 3ActionD Double acting32mm40mm50mm63mm80mm100mm125mmActionDouble acting2050How to OrderDF9NAuto switch typeNilTypeDAuto switch typeY59ANumber of auto switchesNilSWithout auto switch (built-in magnet)Auto switch specificationsSolid stateSpecialfunction—Waterresistant(2 colorindicator)ElectricalentryGrommetIndicatorlightYesNilSn2 pcs.1 pc.Auto switch models Lead wire length (m) ∗Wiring Load voltageElectrical entry direction 0.5Applicable(output)loadsDC AC Perpendicular In-line (Nil) 3 (L) 5 (Z)3 wireF9NV F9N —(NPN)3 wire(PNP)24V2 wire 12VNumber of auto switches2 pcs.1 pc."n" pcs.Nil Without auto switch (built-in magnet)Auto switch specificationsTypeSpecial Electrical Indicator Wiring Load voltage Auto switch models Lead wire length (m) ∗ Applicablefunction entry light (output) DC AC In-line Perpendicular 0.5 (Nil) 3 (L) 5 (Z) loads—3 wire (NPN)Y69A Y59A 5V, 12V3 wire (PNP)Y7PV Y7P IC circuit2 wire12V Y69B Y59B —Diagnostic3 wire (NPN)Relay,Grommet Yes24V 5V, 12V — Y7NWV Y7NW indicationIC circuit3 wire (PNP)Y7PWV Y7PW PLC(2 colorindicator)Y7BWV Y7BW Waterresistant(2 color2 wire12V— Y7BA — —indicator)Solid state5V,12V—F9PVF9BVF9PF9B— F9BA∗ Lead wire length symbols: 0.5m ....... Nil (Example) F9B3m .......... L (Example) F9BL5m .......... Z (Example) F9BZD-F9BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.∗ Lead wire length symbols: 0.5m ..… Nil (Example) Y59B3m…..… L (Example) Y59BL5m…..… Z (Example) Y59BZD-Y7BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.— ——Relay,PLC2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions8

Series <strong>MHS</strong>3Models and SpecificationsModelCylinder bore size mmFluid<strong>MHS</strong>3-16D <strong>MHS</strong>3-20D <strong>MHS</strong>3-25D16 20 25<strong>MHS</strong>3-32D <strong>MHS</strong>3-40D <strong>MHS</strong>3-50D <strong>MHS</strong>3-63D32 40 50 63Air<strong>MHS</strong>3-80D <strong>MHS</strong>3-100D80 100<strong>MHS</strong>3-125D125Operating pressure MPaAmbient and fluid temperature ° C0.2 to 0.6–10 to 600.1 to 0.6Repeatability mm±0.01Max. operating frequency c.p.m.Lubrication12060Non-lube30ActionNote 1)ExternalEffective gripping gripping forceforce N at pressure Internalof 0.5MPagripping forceOpening/closing stroke mm (dia.)Weight g1416460252841004247614074828237Double acting118 187130 2048 12351 54133535916992500525201,850750780243,3401,2701,320326,460Note 1) Values for ø16 to ø25 are with gripping point L = 20mm, for ø32 to ø63 with gripping point L = 30mm, and for ø80 to ø125 with gripping pointL = 50mm.Refer to the "Effective Gripping Force" data on pages 10 through 12 for the gripping force at each gripping position.Note 2) Open and closed diameter values apply for external gripping of work pieces.ConstructionClosed conditionOpen conditionParts listNo.1234567DescriptionBodyPistonCamFingerCapEnd platePiston boltMaterialAluminum alloyAluminum alloyCarbon steelCarbon steelAluminum alloyStainless steelStainless steelNoteHard anodizedHard anodizedHeat treated, Specially treatedHeat treated, Specially treatedHard anodizedNo.8910111213DescriptionRubber magnetC type snap ringPiston sealRod sealGasketGasketMaterialSynthetic rubberCarbon steelNBRNBRNBRNBRNoteNickel platedReplacement parts/Seal kitsKit number<strong>MHS</strong>3-16D <strong>MHS</strong>3-20D <strong>MHS</strong>3-25D <strong>MHS</strong>3-32D <strong>MHS</strong>3-40D <strong>MHS</strong>3-50D <strong>MHS</strong>3-63D <strong>MHS</strong>3-80D <strong>MHS</strong>3-100D <strong>MHS</strong>3-125DContents<strong>MHS</strong>16-PS <strong>MHS</strong>20-PS <strong>MHS</strong>25-PS <strong>MHS</strong>32-PS <strong>MHS</strong>40-PS <strong>MHS</strong>50-PS <strong>MHS</strong>63-PS <strong>MHS</strong>80-PS <strong>MHS</strong>100-PS <strong>MHS</strong>125-PSA set of the aboveNos. 10, 11, 12 and 13∗ Seal kits are sets consisting of items 10, 11, 12 and 13, which can be ordered using the kit number for each cylinder bore size.9

Gripping Point• The work piece gripping point distance should be within the gripping forceranges given for each pressure in the effective gripping force graphsbelow.• If operated with the work piece gripping point beyond the indicated ranges,an excessive offset load will be applied to the sliding section of the fingers,which can have an adverse effect on the service life of the product.Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphsto the right is expressed as F, which is theimpellent force of one finger when all 3 of thefingers and attachments are in full contact with thework piece as shown in the figure below.FExternal gripping force<strong>MHS</strong>3-16DGripping force N3 Finger Air Gripper Series <strong>MHS</strong>325 25LGripping pointExternal grippingInternal grippingL: Gripping point distance20 20Pressure 0.6MPa0.5MPa15 150.4MPa10 100.3MPa5 0.2MPa5<strong>MHS</strong>3-16DGripping force NLGripping pointInternal gripping forcePressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3FExternal grippingFFInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²FF0 5 10 15 20 25 30 0 5 10 15 20 25 30Gripping point L mmGripping point L mm<strong>MHS</strong>3-20D<strong>MHS</strong>3-20DGripping force N35Pressure 0.6MPa300.5MPa25200.4MPa150.3MPa100.2MPa40Pressure 0.6MPa350.5MPa30250.4MPa200.3MPa150.2MPa105 50 5 10 15 20 25 30 35 0 5 10 15 20 25 30 35Gripping point L mmGripping point L mm<strong>MHS</strong>3-25D<strong>MHS</strong>3-25DGripping force N6070Pressure 0.6MPa60Pressure 0.6MPa50500.5MPa0.5MPa40400.4MPa0.4MPa30300.3MPa0.3MPa20200.2MPa0.2MPa10 100 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mmGripping force NGripping force NLong stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions10

Series <strong>MHS</strong>3Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphs tothe right is expressed as F, which is the impellentforce of one finger when all 3 of the fingers andattachments are in full contact with the work pieceas shown in the figure below.FExternal gripping forceInternal gripping force<strong>MHS</strong>3-32D<strong>MHS</strong>3-32DGripping force N100806040Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPaGripping force N12010080604020 0.1MPa20Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaFF0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mm<strong>MHS</strong>3-40D<strong>MHS</strong>3-40DExternal grippingFGripping force N200 200160 Pressure 0.6MPa160Gripping force N120 0.5MPa1200.4MPa80 0.3MPa800.2MPa400.1MPa40Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaFF0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mmInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²<strong>MHS</strong>3-50D<strong>MHS</strong>3-50DGripping force N350 350300 300Gripping force N250Pressure 0.6MPa2502000.5MPa2001500.3MPa0.4MPa1501000.2MPa10050 0.1MPa50Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0 10 20 30 40 50 60 70 0 10 20 30 40 50 60 70Gripping point L mmGripping point L mm<strong>MHS</strong>3-63D<strong>MHS</strong>3-63DGripping force N500 500400Pressure 0.6MPa400Gripping force N0.5MPa300 3000.4MPa200 0.3MPa2000.2MPa100 1000.1MPaPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0 20 40 60 80 100 0 20 40 60 80 100Gripping point L mmGripping point L mm11

External gripping forceInternal gripping force<strong>MHS</strong>3-80D<strong>MHS</strong>3-80DGripping force N700 700Pressure 0.6MPa6006005000.5MPa0.4MPa4003000.3MPa2000.2MPa1000.1MPaPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0020 40 60 80 20 40 60 80Gripping point L mmGripping point L mmGripping force N500400300200100<strong>MHS</strong>3-100D<strong>MHS</strong>3-100D1,000 1,000Pressure 0.6MPa8008000.5MPa6000.4MPa6004000.3MPa4000.2MPa2000.1MPa200Gripping force NGripping force N0020 40 60 80 100Gripping point L mm<strong>MHS</strong>3-125D<strong>MHS</strong>3-125DGripping force N1,800 1,8001,600Pressure 0.6MPa1,6001,4001,4001,2000.5MPa1,2001,0000.4MPa1,0008000.3MPa8006000.2MPa6004000.1MPa400200200Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa20 40 60 80 100Gripping point L mmPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0 20 40 60 80 100 120 0 20 40 60 80 100 120Gripping point L mmGripping point L mmGripping force N3 Finger Air Gripper Series <strong>MHS</strong>32 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions12

Series <strong>MHS</strong>3Dimensions<strong>MHS</strong>3-16D to 25DCB 7P(finger opening port)P(finger closing port)øWA, depth 1.56-M3 x 0.5, thread depth TBAttachment mounting threads3AAABøVA, depth VB22.5°20°20°Open EOClosed ECøBNBNAOQ(Open DO)(Closed DC)3-øSA, counter bore dia. SB, counter bore depth SCP.C.D.R (mounting hole)JK2H9 +0.02502IGFX FY FZXA, depth XB3-UA, thread depth UBP.C.D.R (mounting threads)Auto switch mounting groove positions (2 locations)<strong>MHS</strong>3-16D <strong>MHS</strong>3-20D <strong>MHS</strong>3-25D5654°ø4554°335ø454°6.5535ø433°33°33°Model<strong>MHS</strong>3-16D<strong>MHS</strong>3-20D<strong>MHS</strong>3-25DAA353840AB323537B303642CB111315DC151821DO172024EC567EO7810FX12.514.517FY111314.5FZ335G252728I455J101214K456NA81012NB05h9 -0.03006h9 -0.03006h9 -0.030O22.53PM3 x 0.5M5 x 0.8M5 x 0.8Q678(mm)R25293413Model<strong>MHS</strong>3-16D<strong>MHS</strong>3-20D<strong>MHS</strong>3-25DSA3.43.44.5SB6.56.58SC89.510TB566UAM3 x 0.5M3 x 0.5M4 x 0.7UB4.566VA2H92H93H9+0.0250+0.0250+0.0250VB223WA17H921H926H9+0.0430+0.0520+0.0520XA2H92H93H9+0.0250+0.0250+0.0250XB223

<strong>MHS</strong>3-32D to 80DCB3 Finger Air Gripper Series <strong>MHS</strong>3CAP(finger opening port)2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>36-TA, thread depth TBAttachment mounting threads(Open DO)(Closed DC)ACOpen EOClosed ECAAABP(finger closing port)øBøVA, depth VB22.5°20°20°øWA, depth WBWith dust cover<strong>MHS</strong>J3NANBOQ3-øSA, counter bore dia. SB, counter bore depth SCP.C.D.R (mounting hole)JKLMIGFXFY FZXA, depth XB3-UA, thread depth UBP.C.D.R (mounting threads)Through hole<strong>MHS</strong>H3Auto switch mounting groove positions (4 locations)10°10°Long stroke<strong>MHS</strong>L36.4540°Y40°4 finger <strong>MHS</strong>4 Auto switchesModel<strong>MHS</strong>3-32D<strong>MHS</strong>3-40D<strong>MHS</strong>3-50D<strong>MHS</strong>3-63D<strong>MHS</strong>3-80DAA4447556682AB4144526277AC33345B52627086106CA8991213.5CB1617202227DC2831354353.5DO3235415163.5EC810111521.5EO1214172331.5FX2226.5313847.5FY19.523.52834.543.5FZ56678G30.53237.54456I6791112J2021242832K99101112L2H93H94H96H98H9+0.0250+0.0250+0.0300+0.0300+0.0360M22234NA1416182428(mm)NB08h9 -0.03608h9 -0.036010h9 -0.036012h9 -0.043014h9 -0.043Model selectionModel<strong>MHS</strong>3-32D<strong>MHS</strong>3-40D<strong>MHS</strong>3-50D<strong>MHS</strong>3-63D<strong>MHS</strong>3-80DO4.54.555.56PM5 x 0.8M5 x 0.8M5 x 0.8M5 x 0.8Rc 1/8Q1112141720R4453627695SA4.55.55.56.66.6SB89.59.51111SC99121419TAM4 x 0.7M4 x 0.7M5 x 0.8M5 x 0.8M6 x 1TB88101012UAM4 x 0.7M5 x 0.8M5 x 0.8M6 x 1M6 x 1UB67.510912VA3H94H94H95H96H9+0.0250+0.0300+0.0300+0.0300+0.0300VB34456WA WB+0.062 34H9 0 2+0.06242H9 0 2+0.07452H9 0 2+0.07465H9 0 2.5+0.08782H9 0 3XA3H94H94H95H96H9+0.0250+0.0300+0.0300+0.0300+0.0300XB34456Y6877.5814Precautions

15Series <strong>MHS</strong>3Dimensions<strong>MHS</strong>3-100D, 125DCBCAP(finger opening port)P(finger closing port)6-TA, thread depth TBAttachment mounting threadsACAAABøVA, depth VB22.5°20°20°øWA, depth WBOOpen EOClosed ECøBNANBQ(Open DO)(Closed DC)J3-øSA, counter bore dia. SB, counter bore depth SCP.C.D.R (mounting hole)KLMIGFXFY FZXA, depth XB3-UA, thread depth UBP.C.D.R (mounting threads)Auto switch mounting groove positions (4 locations)<strong>MHS</strong>3-100D<strong>MHS</strong>3-125D10°10°10°10°40°40°40°40°56.41090°1356.4125790°Model<strong>MHS</strong>3-100D<strong>MHS</strong>3-125DAA96122AB90114AC68B134166CA1823.5CB30.638DC6682DO7898EC2830EO4046FX5974FY5468FZ1012G6384I1518J3852K1521L8H910H9+0.0360+0.0360M46NA3440(mm)NB018h9 -0.043022h9 -0.052Model<strong>MHS</strong>3-100D<strong>MHS</strong>3-125DO7.510.5PRc 1/4Rc 3/8Q2331R118148SA911SB1417.5SC2134TAM8 x 1.25M10 x 1.5TB1620UAM8 x 1.25M10 x 1.5UB1620VA8H910H9+0.0360+0.0360VB68WA102H9130H9+0.0870+0.1000WB46XA8H910H9+0.0360+0.0360XB6815

3 FingerAir GripperParallel TypeWith Dust CoverSeries <strong>MHS</strong>J3ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80How to Order2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust coverNilFS<strong>MHS</strong>J 3Number of fingers3 3 fingersCylinder bore size162025324050638016mm20mm25mm32mm40mm50mm63mm80mmDust cover typeChloroprene rubber (CR)Fluoro rubber (FKM)Silicon rubber (Si)Models and SpecificationsModel <strong>MHS</strong>J3-16DCylinder bore size mm 16FluidOperating pressure MPaAmbient and fluid temperature °CRepeatability mmMax. operating frequency c.p.m.LubricationActionNote 1)ExternalEffective gripping force gripping force 9N at pressure of 0.5MPa Internalgripping force 16Opening/closing stroke mm (dia.) 4Weight g9532 DActionD Double actingAuto switch typeNil Without auto switch (built-in magnet)Type<strong>MHS</strong>J3-20D200.2 to 0.612021284150—<strong>MHS</strong>J3-25D2536476230F9NAuto switch specificationsSolid stateSpecialfunctionWaterresistant(2 colorindicator)ElectricalentryGrommet<strong>MHS</strong>J3-32D32<strong>MHS</strong>J3-40D40<strong>MHS</strong>J3-50D50<strong>MHS</strong>J3-63D63<strong>MHS</strong>J3-80D80Air0.1 to 0.6–10 to 60±0.016030Non-lubeDouble acting62828440Number of auto switchesNilS9713086202 pcs.1 pc.Auto switch models Lead wire length (m) ∗ Indicator Wiring Load voltagelightElectrical entry direction(output)0.5ApplicableloadsDC AC Perpendicular In-line (Nil) 3 (L) 5 (Z)3 wireF9NV F9N —(NPN) 5V,3 wire 12V(PNP)F9PV F9P —Yes 24VRelay,—PLCF9BV F9B —2 wire 12V— F9BA — ∗ Lead wire length symbols: 0.5m ..… Nil (Example) F9B3m ....…. L (Example) F9BL5m ....…. Z (Example) F9BZD-F9BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.155204121,050280359161,800Note 1) Values for ø16 to ø25 are with gripping point L = 20mm, for ø32 to ø63 with gripping point L = 30mm, and for ø80 to ø125 with gripping point L = 50mm.Refer to the "Effective Gripping Force" data on pages 18 through 20 for the gripping force at each gripping position.Note 2) Open and closed diameter values apply for external gripping of work pieces.400525203,200With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions16

Series <strong>MHS</strong>J3Constructionø16 to ø25Closed conditionOpen conditionø32 to ø80Open conditionParts listNo.1234567DescriptionBodyPistonCam (J)FingerCap (J)End plate (J)GuideMaterialAluminum alloyø16 to ø25: Stainless steelø32 to ø80: Aluminum alloyCarbon steelCarbon steelAluminum alloyStainless steelAluminum alloyNoteHard anodizedHard anodizedHeat treated, Specially treatedHeat treated, Specially treatedHard anodizedHard anodizedNo.89101112131415DescriptionRubber magnetHexagon socket head screwParallel pinC type snap ringGasketGasketPiston sealRod sealMaterialSynthetic rubberCarbon steelStainless steelCarbon steelNBRNBRNBRNBRNoteNickel platedNickel platedReplacement parts/Seal kits<strong>MHS</strong>J3-16D<strong>MHS</strong>J3-20D <strong>MHS</strong>J3-25DKit number<strong>MHS</strong>J3-32D <strong>MHS</strong>J3-40D <strong>MHS</strong>J3-50D <strong>MHS</strong>J3-63D<strong>MHS</strong>J3-80DContents<strong>MHS</strong>J16-PS <strong>MHS</strong>J20-PS <strong>MHS</strong>J25-PS <strong>MHS</strong>J32-PS <strong>MHS</strong>J40-PS <strong>MHS</strong>J50-PS <strong>MHS</strong>J63-PS <strong>MHS</strong>J80-PSA set of the aboveNos. 12, 13, 14 & 15∗ Seal kits are sets consisting of items 12, 13, 14 and 15, which can be ordered using the kit number for each cylinder bore size.Replacement parts/Dust cover (J)No.16Description MaterialCR Note)Dust cover (J) FKM Note)Si Note)<strong>MHS</strong>J3-16D<strong>MHS</strong>J3-J16 <strong>MHS</strong>J3-J20<strong>MHS</strong>J3-J16F <strong>MHS</strong>J3-J20F<strong>MHS</strong>J3-J16S <strong>MHS</strong>J3-J20SNote) CR: Chloroprene rubber, FKM: Fluoro rubber, Si: Silicon rubber<strong>MHS</strong>J3-20D <strong>MHS</strong>J3-25D<strong>MHS</strong>J3-J25<strong>MHS</strong>J3-J25F<strong>MHS</strong>J3-J25SPart number<strong>MHS</strong>J3-32D <strong>MHS</strong>J3-40D <strong>MHS</strong>J3-50D <strong>MHS</strong>J3-63D<strong>MHS</strong>J3-J32 <strong>MHS</strong>J3-J40 <strong>MHS</strong>J3-J50 <strong>MHS</strong>J3-J63<strong>MHS</strong>J3-J32F <strong>MHS</strong>J3-J40F <strong>MHS</strong>J3-J50F <strong>MHS</strong>J3-J63F<strong>MHS</strong>J3-J32S <strong>MHS</strong>J3-J40S <strong>MHS</strong>J3-J50S <strong>MHS</strong>J3-J63S<strong>MHS</strong>J3-80D<strong>MHS</strong>J3-J80<strong>MHS</strong>J3-J80F<strong>MHS</strong>J3-J80S17

Gripping Point• The work piece gripping point distance should be within the gripping forceranges given for each pressure in the effective gripping force graphsbelow.• If operated with the work piece gripping point beyond the indicated ranges,an excessive offset load will be applied to the sliding section of the fingers,which can have an adverse effect on the service life of the product.Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in thegraphs to the right is expressed as F, which isthe impellent force of one finger when all 3 ofthe fingers and attachments are in full contactwith the work piece as shown in the figurebelow.FExternal gripping force<strong>MHS</strong>J3-16DGripping force N151053 Finger Air Gripper Series <strong>MHS</strong>J3LPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPaGripping point<strong>MHS</strong>J3-16DGripping force N252015105Gripping pointExternal grippingInternal grippingL: Gripping point distanceInternal gripping forceLPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3FExternal grippingFFInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²FF005 10 15 20 25 305 10 15 20 25 30Gripping point L mmGripping point L mm<strong>MHS</strong>J3-20D<strong>MHS</strong>J3-20DGripping force N3530Pressure 0.6MPa25200.5MPa0.4MPa150.3MPa100.2MPa40Pressure 0.6MPa35300.5MPa250.4MPa200.3MPa15100.2MPa5505 10 15 20 25 30 350 5 10 15 20 25 30 35Gripping point L mmGripping point L mm<strong>MHS</strong>J3-25DGripping force N706050Pressure 0.6MPa400.5MPa300.4MPa200.3MPa0.2MPa10Gripping force N<strong>MHS</strong>J3-25D0010 20 30 40 5010 20 30 40 50Gripping point L mmGripping point L mmGripping force N7060Pressure 0.6MPa500.5MPa400.4MPa300.3MPa200.2MPa10Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions18

Series <strong>MHS</strong>J3Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphsto the right is expressed as F, which is theimpellent force of one finger when all 3 of thefingers and attachments are in full contact withthe work piece as shown in the figure below.FExternal gripping forceInternal gripping force<strong>MHS</strong>J3-32D<strong>MHS</strong>J3-32DGripping force N100 12080Pressure 0.6MPa0.5MPa600.4MPa400.3MPa0.2MPa200.1MPaGripping force N10080604020Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa010 20 30 40 500 10 20 30 40 50FFGripping point L mmGripping point L mm<strong>MHS</strong>J3-40D<strong>MHS</strong>J3-40DExternal grippingFGripping force N1601208040Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaGripping force N2001601208040Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaFF0010 20 30 40 5010 20 30 40 50Gripping point L mmGripping point L mmInternal gripping<strong>MHS</strong>J3-50D250<strong>MHS</strong>J3-50D3501N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²Gripping force N200150100500.3MPa0.2MPa0.1MPaPressure 0.6MPa0.5MPa0.4MPaGripping force N30025020015010050Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa010 20 30 40 50 60 700 10 20 30 40 50 60 70Gripping point L mmGripping point L mm<strong>MHS</strong>J3-63D400<strong>MHS</strong>J3-63D500Gripping force N300200100Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaGripping force N400300200100Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa020040 60 80 10020 40 60 80 100Gripping point L mmGripping point L mm19

External gripping forceInternal gripping force<strong>MHS</strong>J3-80D<strong>MHS</strong>J3-80DGripping force N600500Pressure 0.6MPa4000.5MPa0.4MPa3000.3MPa2000.2MPa1000.1MPa0020 40 60 8020 40 60 80Gripping point L mmGripping point L mmGripping force N3 Finger Air Gripper Series <strong>MHS</strong>J3700Pressure 0.6MPa6000.5MPa5000.4MPa4000.3MPa3000.2MPa2000.1MPa1002 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions20

5ø46ø4ø4Series <strong>MHS</strong>J3Dimensions<strong>MHS</strong>J3-16D to 25D6-M3 x 0.5, thread depth TBAttachment mounting threadsP(finger opening port)CB CAFX3-M4 x 0.7, thread depth 8P.C.D.R (mounting threads)SDSDNBOQ(Open DO)(Closed DC)3-ø3.2, counter bore dia. SB, counter bore depth 4 (See section SD-SD)P.C.D.R (mounting hole)øHAOpen EOClosed ECJK2H9 +0.025023 AD AEAAøB30°20°øHB20°P(finger closing port)+0.025ø3H9 0 , depth 3øWA, depth 1.5(Counter bore depth 4)(Counter bore dia. SB)AI(3-ø3.2)Section SD - SDAuto switch mounting groove positions (2 locations)<strong>MHS</strong>J3-16D <strong>MHS</strong>J3-20D <strong>MHS</strong>J3-25D320°20°590°536.55590°320°20°20°20°Model<strong>MHS</strong>J3-16D<strong>MHS</strong>J3-20D<strong>MHS</strong>J3-25DAA464955AD161820AE272832AI394247B303642CA777.5CB141417.5DC17.52023.5DO19.52226.5EC7.589.5EO9.51012.5FX121518HA445059HB364250J101214K456NB05h9 -0.03006h9 -0.03006h9 -0.030O22.53PM3 x 0.5M5 x 0.8M5 x 0.8(mm)Q67821Model<strong>MHS</strong>J3-16D<strong>MHS</strong>J3-20D<strong>MHS</strong>J3-25DR242934SB66.56.5TB566WA17H921H926H9+0.0430+0.0520+0.0520

<strong>MHS</strong>J3-32D to 80D6-TA, thread depth TBAttachment mounting threads3 Finger Air Gripper Series <strong>MHS</strong>J3CBCAP(finger opening port)30°20°20°3-UA, thread depth UBP.C.D.R (mounting threads)FX3-YA, thread depth YBP.C.D.R2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3AISDSDOQ(Open DO)(Closed DC)øHAOpen EOK Closed ECNBMAC AD AEAA3-øSA, counter bore dia. SB, counter bore depth SC (See section SD - SD)P.C.D.R (mounting hole)(Counter bore depth SC)(Counter bore dia. SB)7590°JLAuto switch mounting groove positions (2 locations)<strong>MHS</strong>J3-32D53ø47590°5øB<strong>MHS</strong>J3-40D3P(finger closing port)ø4øHB7.5590°5<strong>MHS</strong>J3-50D3øVA, depth VBøWA, depth WBø4With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L3(3-øSA)Section SD - SD10590°35<strong>MHS</strong>J3-63Dø420°20°20°20°11590°5320°<strong>MHS</strong>J3-80Dø420°4 finger <strong>MHS</strong>4 Auto switchesModel<strong>MHS</strong>J3-32D<strong>MHS</strong>J3-40D<strong>MHS</strong>J3-50D<strong>MHS</strong>J3-63D<strong>MHS</strong>J3-80DAA6366809110820°AC33345AD242631374620°AE3637465057AI5457707993B54627492112CA9.510.511.51314CB191926.52831DC31.536425163DO35.540485973EC11.515182331EO15.519243141FX2226324050HA7686103125158HB65758810613020°J2021242832K9910111220°L2H93H94H96H98H9+0.0250+0.0250+0.0300+0.0300+0.0360M22234(mm)NB08h9 -0.03608h9 -0.036010h9 -0.036012h9 -0.043014h9 -0.043Model selectionModel<strong>MHS</strong>J3-32D<strong>MHS</strong>J3-40D<strong>MHS</strong>J3-50D<strong>MHS</strong>J3-63D<strong>MHS</strong>J3-80DO4.54.555.56PM5 x 0.8M5 x 0.8M5 x 0.8M5 x 0.8Rc 1/8Q1112141720R4452637898SA4.24.25.16.66.6SB889.51111SC77888TAM4 x 0.7M4 x 0.7M5 x 0.8M5 x 0.8M6 x 1TB88101012UAM5 x 0.8M5 x 0.8M6 x 1M8 x 1.25M8 x 1.25UB1010121616VA4H94H95H96H96H9+0.0300+0.0300+0.0300+0.0300+0.0300VB44566WA34H942H952H965H982H9+0.0620+0.0620+0.0740+0.0740+0.0870WB2222.53YAM4 x 0.7M4 x 0.7M5 x 0.8M6 x 1M6 x 1YB8810121222Precautions

3 FingerAir GripperParallel TypeThrough HoleSeries <strong>MHS</strong>H3ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80<strong>MHS</strong>H3How to Order32 D F9NThrough holeDust coverNil Without dust coverJ With dust coverNote) ø16, ø20 and ø25 are notavailable with dust cover.1620253240506380Number of fingersCylinderbore size16mm20mm25mm32mm40mm50mm63mm80mm<strong>MHS</strong>H 3Through holeNumberof fingers3 3 fingers3 3 fingersCenter pusher assemblyAir grippercylinder bore size324050638032mm40mm50mm63mm80mmActionD Double actingNilABCenter pusherWithout center pusherCylinder typeSpring typeCenter Pusher Assembly23Note) ø16, ø20 and ø25 are notavailable with center pusher.A50 ACenter pusherABCylinder typeSpring typeAuto switch typeNilTypeF9NDust cover type(with dust cover only)NilFSChloroprene rubber (CR)Fluoro rubber (FKM)Silicon rubber (Si)Without auto switch (built-in magnet)Auto switch specificationsSolid stateSpecialfunction—Waterresistant(2 colorindicator)Auto switch type (cylinder type only)Nil Without auto switch (built-in magnet)Auto switch specificationsTypeSolid stateSpecialfunction—Number of auto switchesNil 2 pcs.S 1 pc.n Note 2) "n" pcs.Note) Symbol entry examples when mountingauto switches on air gripper withcylinder type center pusher1. Air gripper unit ..........1 pc.}Total of 2 pcs.→NilCenter pusher unit ....1 pc.<strong>MHS</strong>H3-32DA-F9N2. Air gripper unit ......... 2 pcs.}Total of 4 pcs.→Enter "4"Center pusher unit ... 2 pcs.<strong>MHS</strong>H3-32DA-F9N4Auto switch models Lead wire length (m) ∗Electrical Indicator Wiring Load voltageElectrical entry directionApplicableentry light (output)0.5 3 5loadsDC AC Perpendicular In-line (Nil) (L) (Z)3 wireF9NV F9N —(NPN) 5V,3 wire 12V(PNP)F9PV F9P —Grommet YesRelay,24V —PLCF9BV F9B —2 wire 12V— F9BA — ∗ Lead wire length symbols: 0.5m ..… Nil (Example) F9B3m…..… L (Example) F9BL5m…..… Z (Example) F9BZD-F9BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.Waterresistant(2 colorindicator)ElectricalentryGrommetIndicatorlightYesWiring(output)3 wire(NPN)3 wire(PNP)24V2 wire 12VNumber of auto switches—NilSF9PVF9BV2 pcs.1 pc.Load voltageAuto switch models Lead wire length (m) ∗Electrical entry direction 0.5 3 5 ApplicableDC AC Perpendicular In-line (Nil) (L) (Z) loads5V,F9NV F9N —12VF9PF9B— F9BA∗ Lead wire length symbols: 0.5m ..… Nil (Example) F9B3m .....… L (Example) F9BL5m .....… Z (Example) F9BZD-F9BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.Note 3) Auto switches for center pusher assembly are available only on the cylinder type.— ——Relay,PLC

3 Finger Air Gripper Series <strong>MHS</strong>H3ConstructionCenter pusher/cylinder typeReplacement parts/Seal kits (center pusher/cylinder type)Kit number<strong>MHS</strong>H3-A32A <strong>MHS</strong>H3-A40A <strong>MHS</strong>H3-A50AParts listNo.Description1 Push holder (P)2 Piston (P)3 Rod holder4 Bumper5 Push rod (P)6 Rubber magnet7 Hexagon socket head screw8 C type snap ring9 Steel ball10 Gasket11 Gasket12 Piston seal13 Rod seal<strong>MHS</strong>H3-A63A<strong>MHS</strong>H3-A80A<strong>MHS</strong>H32A-PS <strong>MHS</strong>H40A-PS <strong>MHS</strong>H50A-PS <strong>MHS</strong>H63A-PS <strong>MHS</strong>H80A-PSMaterialNoteAluminum alloy Hard anodizedAluminum alloy Hard anodizedAluminum alloy Hard anodizedUrethane rubberStainless steel Hard chromedSynthetic rubberCarbon steel Nickel platedCarbon steel Nickel platedStainless steelNBRNBRNBRNBRContentsA set of the above Nos. 10, 11, 12 & 132 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L3∗ Seal kits are sets consisting of items 10, 11, 12 and 13, which can be ordered using the kit number for each cylinder bore size.ConstructionCenter pusher/spring typeParts listNo.Description1 Push holder (S)2 Cap (S)3 Spring holder4 Spring5 Push rod (S)6 Hexagon socket head screw7 Hexagon socket head screw8 C type snap ringMaterialAluminum alloyStainless steelStainless steelStainless steelStainless steelCarbon steelCarbon steelCarbon steelNoteHard anodizedHard chromedNickel platedNickel platedNickel plated4 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions26

Series <strong>MHS</strong>H3Gripping Point• The work piece gripping point distance should be within the gripping forceranges given for each pressure in the effective gripping force graphsbelow.• If operated with the work piece gripping point beyond the indicatedranges, an excessive offset load will be applied to the sliding section ofthe fingers, which can have an adverse effect on the service life of theproduct.LGripping pointLGripping pointExternal grippingInternal grippingL: Gripping point distanceEffective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphs tothe right is expressed as F, which is the impellentforce of one finger when all 3 of the fingers andattachments are in full contact with the work pieceas shown in the figure below.FExternal gripping force<strong>MHS</strong>H3-16DGripping force N15Pressure 0.6MPa100.5MPa0.4MPa0.3MPa50.2MPaInternal gripping force<strong>MHS</strong>H3-16DGripping force N25Pressure 0.6MPa200.5MPa150.4MPa100.3MPa50.2MPaFF005 10 15 20 25 30 5 10 15 20 25 30Gripping point L mmGripping point L mmExternal grippingFFInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²F<strong>MHS</strong>H3-20DGripping force N3530Pressure 0.6MPa250.5MPa200.4MPa150.3MPa100.2MPa<strong>MHS</strong>H3-20D4035Pressure 0.6MPa300.5MPa250.4MPa200.3MPa150.2MPa10550 5 10 15 20 25 30 3505 10 15 20 25 30 35Gripping point L mmGripping point L mm<strong>MHS</strong>H3-25DGripping force N706050Pressure 0.6MPa400.5MPa300.4MPa200.3MPa0.2MPa10Gripping force N<strong>MHS</strong>H3-25DGripping force N7060Pressure 0.6MPa500.5MPa400.4MPa300.3MPa200.2MPa100010 20 30 40 50 10 20 30 40 50Gripping point L mmGripping point L mm27

Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphsto the right is expressed as F, which is theimpellent force of one finger when all 3 of thefingers and attachments are in full contact with thework piece as shown in the figure below.FExternal grippingFFInternal grippingF1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm 2FFExternal gripping forceInternal gripping force<strong>MHS</strong>H3-32D<strong>MHS</strong>H3-32DGripping force N10080Pressure 0.6 MPa0.5MPa600.4MPa400.3MPa0.2MPa200.1MPa120100Pressure 0.6MPa800.5MPa0.4MPa600.3MPa400.2MPa200.1MPa00 10 20 30 40 50 10 20 30 40 50Gripping point L mmGripping point L mm<strong>MHS</strong>H3-40D<strong>MHS</strong>H3-40DGripping force N160Pressure 0.6 MPa1200.5MPa800.4MPa0.3MPa400.2MPa0.1MPa0010 20 30 40 5010 20 30 40 50Gripping point L mmGripping point L mm<strong>MHS</strong>H3-50D<strong>MHS</strong>H3-50DGripping force N250200150100503 Finger Air Gripper Series <strong>MHS</strong>H3Pressure 0.6MPa0.5MPa0.3MPa0.4MPa0.2MPa0.1MPaGripping force NGripping force N200160Pressure 0.6MPa1200.5MPa0.4MPa800.3MPa0.2MPa400.1MPa0010 20 30 40 50 60 70 10 20 30 40 50 60 70Gripping point L mmGripping point L mm<strong>MHS</strong>H3-63D<strong>MHS</strong>H3-63DGripping force N400500350300250Pressure 0.6MPa2000.5MPa150 0.3MPa0.4MPa100 0.2MPa50 0.1MPa2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesGripping force N300200100Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaGripping force N400300200100Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaModel selection020 40 60 80 100 0 20 40 60 80 100Gripping point L mmGripping point L mmPrecautions28

Series <strong>MHS</strong>H3Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphsto the right is expressed as F, which is theimpellent force of one finger when all 3 of thefingers and attachments are in full contact withthe work piece as shown in the figure below.External gripping force<strong>MHS</strong>H3-80D600Internal gripping force<strong>MHS</strong>H3-80D700500Pressure 0.6MPa600Pressure 0.6MPaFFFGripping force N4003002000.5MPa0.4MPa0.3MPa0.2MPaGripping force N5004003002000.5MPa0.4MPa0.3MPa0.2MPa1000.1MPa1000.1MPaExternal gripping0020 40 60 80 20 40 60 80FGripping point L mmGripping point L mmFFInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²Effective Thrust of Center PusherCylinder type (Note1)Spring typePA<strong>MHS</strong>H3-32DA6050PA<strong>MHS</strong>H3-32DB1110PBPA: Pusher thrustPusher thrust N403020Spring force N987PB1060 0.1 0.2 0.3 0.4 0.5 0.601 2 3 4 5 6PB: Spring force<strong>MHS</strong>H3-40DA180Supply pressure MPa<strong>MHS</strong>H3-40DB16Pusher stroke mm150PA15PBPusher thrust N1209060Spring force N141312301100 0.1 0.2 0.3 0.4 0.5 0.6 1 2 3 4 5 6Supply pressure MPaPusher stroke mm29Note1) The thrust of the cylinder type is on extension ofthe push rod.

Effective Thrust of Center PusherPAPA: Pusher thrustPBPB: Spring forcePusher thrust N3 Finger Air Gripper Series <strong>MHS</strong>H3Cylinder type (Note1)Spring type<strong>MHS</strong>H3-50DA<strong>MHS</strong>H3-50DB300250PA200150100500 0.1 0.2 0.3 0.4 0.5 0.6Supply pressure MPa<strong>MHS</strong>H3-63DA<strong>MHS</strong>H3-63DB60034Spring force N25PB24232221200 2 4 6 8 10 12Pusher stroke mm2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Pusher thrust N500400300200PASpring force N33323130PBThrough hole<strong>MHS</strong>H31000 0.1 0.2 0.3 0.4 0.5 0.6 0 2 4 6 8 10 12<strong>MHS</strong>H3-80DAPusher thrust N900750600450300150Supply pressure MPaPASupply pressure MPa29<strong>MHS</strong>H3-80DBSpring force N595755535149Pusher stroke mm0 0.1 0.2 0.3 0.4 0.5 0.6 0 3 6 9 12 15 18Note1) The thrust of the cylinder type is on extension ofthe push rod.PBPusher stroke mmLong stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions30

ø4ø4Series <strong>MHS</strong>H3Dimensions: Center Pusher/Cylinder Type<strong>MHS</strong>H3-32DA to 80DAPusher extended ZFPusher retracted ZGThread depth UD M5 x 0.8(pusher retraction port)3-UC3-øUECCFXCCøZDZEøBEøBFøBGZJøVA, depth VBZH, thread depth ZIAJAHAG(AF)M5 x 0.8(pusher extension port)Center pusher auto switch mounting groove positions (2 locations)<strong>MHS</strong>H3-32DA<strong>MHS</strong>H3-40DA<strong>MHS</strong>H3-50DAø46.33.351235.72.751238.85.86316<strong>MHS</strong>H3-63DA<strong>MHS</strong>H3-80DAø4ø410.27.2311.28.26 6318 21Note) For dimensions, refer to the <strong>MHS</strong>H3-32 to 80Ddimensions on page 32.(mm)Model<strong>MHS</strong>H3-32DA<strong>MHS</strong>H3-40DA<strong>MHS</strong>H3-50DA<strong>MHS</strong>H3-63DA<strong>MHS</strong>H3-80DAAF3536444858AG2627333545AH912151820AJ99111313BE3038485868BF032h9 -0.062040h9 -0.062050h9 -0.062060h9 -0.074070h9 -0.074BG53.561.573.591.5111.5CC9.513.517.52025FX2226324050UCM5 x 0.8M5 x 0.8M6 x 1M8 x 1.25M8 x 1.25UD1010121616UE5.55.56.68.68.6VA4H94H95H96H96H9+0.0300+0.0300+0.0300+0.0300+0.0300VB44566ZD610121620ZE58101417ZF2021283241ZG1516182226ZHM3 x 0.5M5 x 0.8M6 x 1M8 x 1.25M10 x 1.5ZI610121620ZJ3.54.557833

Series <strong>MHS</strong>H3Dimensions: Through Hole with Dust Cover<strong>MHS</strong>HJ3-32D to 80D6-TA, thread depth TBAttachment mounting threadsCBCAP(finger opening port)20°3-UA, thread depth UBP.C.D.R (mounting threads)FX3-YA, thread depth YBP.C.D.R20°SDSDNBOQ(Closed DC)øHAJ Open EOK Closed EC3-øSA, counter bore dia. SB, counter bore depth SC (See section SD - SD)P.C.D.R (mounting hole)(Open DO)LMAC AD AEAAøBøHBøZAP(finger closing port)øVA, depth VBøWA, depth WBAI(Counter bore depth SC)(Counter bore dia. SB)75<strong>MHS</strong>HJ3-32D3590°20°20°ø4Auto switch mounting groove positions (2 locations)75<strong>MHS</strong>HJ3-40D3590°20°20°ø47.5590°<strong>MHS</strong>HJ3-50D3520°20°ø4(3-øSA)Section SD - SD<strong>MHS</strong>HJ3-63D<strong>MHS</strong>HJ3-80D10590°35ø411590°35ø420°20°20°20°Model<strong>MHS</strong>HJ3-32D<strong>MHS</strong>HJ3-40D<strong>MHS</strong>HJ3-50D<strong>MHS</strong>HJ3-63D<strong>MHS</strong>HJ3-80DAA63668091108AC33345AD2426313746AE3637465057AI5457707993B54627492112CA9.510.511.51314CB191926.52831DC31.536425163DO35.540485973EC11.515182331EO15.519243141FX2226324050HA7686103125158HB657588106130J2021242832K99101112L2H93H94H96H98H9+0.0250+0.0250+0.0300+0.0300+0.0360M22234(mm)NB08h9 -0.03608h9 -0.036010h9 -0.036012h9 -0.043014h9 -0.043Model<strong>MHS</strong>HJ3-32D<strong>MHS</strong>HJ3-40D<strong>MHS</strong>HJ3-50D<strong>MHS</strong>HJ3-63D<strong>MHS</strong>HJ3-80DO4.54.555.56PM5 x 0.8M5 x 0.8M5 x 0.8M5 x 0.8Rc 1/8Q1112141720R4452637898SA4.24.25.16.66.6SB889.51111SC77888TAM4 x 0.7M4 x 0.7M5 x 0.8M5 x 0.8M6 x 1TB88101012UAM5 x 0.8M5 x 0.8M6 x 1M8 x 1.25M8 x 1.25UB1010121616VA4H94H95H96H96H9+0.0300+0.0300+0.0300+0.0300+0.0300VB44566WA34H942H952H965H982H9+0.0620+0.0620+0.0740+0.0740+0.0870WB2222.53YAM4 x 0.7M4 x 0.7M5 x 0.8M6 x 1M6 x 1YB88101212ZA6H1010H1012H1016H1020H10+0.0480+0.0580+0.0700+0.0700+0.084035

Dimensions: Center Pusher/Cylinder Type with Dust Cover<strong>MHS</strong>HJ3-32DA to 80DAZH, thread depth ZIPusher extended ZFPusher retracted ZG3-UC3 Finger Air Gripper Series <strong>MHS</strong>H3M5 x 0.8(pusher retraction port)Thread depth UDCCFXCC2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3øZDZEZJøBEøBFøBGøVA, depth VBWith dust cover<strong>MHS</strong>J3AJAHAG(AF)M5 x 0.8(pusher extension port)Through hole<strong>MHS</strong>H3Note) For dimensions, refer to the <strong>MHS</strong>HJ3-32 to 80Ddimensions on page 35.For auto switch mounting groove dimensions for the centerpusher, refer to <strong>MHS</strong>H3-32 to 80DA on page 33.Long stroke<strong>MHS</strong>L3Model<strong>MHS</strong>HJ3-32DA<strong>MHS</strong>HJ3-40DA<strong>MHS</strong>HJ3-50DA<strong>MHS</strong>HJ3-63DA<strong>MHS</strong>HJ3-80DAAF3536444858AG2627333545AH912151820AJ99111313BE3038485868BF032h9 -0.062040h9 -0.062050h9 -0.062060h9 -0.074070h9 -0.074BG53.561.573.591.5111.5CC9.513.517.52025FX2226324050UCM5 x 0.8M5 x 0.8M6 x 1M8 x 1.25M8 x 1.25UD1010121616VA+0.0304H9 0+0.0304H9 0+0.030 5H9 0+0.0306H9 0+0.0306H9 0VB44566ZD610121620ZE58101417ZF1415212431ZG910111416ZHM3 x 0.5M5 x 0.8M6 x 1M8 x 1.25M10 x 1.5ZI610121620(mm)ZJ3.54.55784 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions36

Series <strong>MHS</strong>H3Dimensions: Center Pusher/Spring Type with Dust Cover<strong>MHS</strong>HJ3-32DB to 80DBThread depth UDZH, thread depth ZIPusher extended ZFPusher retracted ZG3-UC3-øUEFXøZDZEøBFøBGøBEøBFøBGZJøVA, depth VBAJAHAG(AF)øWC, depth WDAHAF<strong>MHS</strong>HJ3-32DB, 40DBNote) For dimensions, refer to the <strong>MHS</strong>HJ3-32 to 80Ddimensions on page 35.Model<strong>MHS</strong>HJ3-32DB<strong>MHS</strong>HJ3-40DB<strong>MHS</strong>HJ3-50DB<strong>MHS</strong>HJ3-63DB<strong>MHS</strong>HJ3-80DBAF1821303548AG——192235AH912151820AJ99111313BE——485868BF032h9 -0.062040h9 -0.062050h9 -0.062060h9 -0.074070h9 -0.074BG53.561.573.591.5111.5FX2226324050UCM5 x 0.8M5 x 0.8M6 x 1M8 x 1.25M8 x 1.25UD1010121616UE5.55.56.68.68.6VA4H94H95H96H96H9+0.0300+0.0300+0.0300+0.0300+0.0300VB44566WC+0.120 0+0.124 0+0.132 0+0.142 0+0.1 52 0WD1.51.51.522ZD610121620ZE58101417(mm)ZF1415212431Model<strong>MHS</strong>HJ3-32DB<strong>MHS</strong>HJ3-40DB<strong>MHS</strong>HJ3-50DB<strong>MHS</strong>HJ3-63DB<strong>MHS</strong>HJ3-80DBZG910111416ZHM3 x 0.5M5 x 0.8M6 x 1M8 x 1.25M10 x 1.5ZI610121620ZJ3.54.557837

3 FingerAir GripperParallel TypeCylinder Bore Sizeø16 to ø25Cylinder Bore Sizeø32 to ø125SymbolNumber of fingers3 3 fingersNumber of fingers<strong>MHS</strong>L 3Cylinder bore size3 3 fingersD162025Cylinder bore size3240506380100125Series <strong>MHS</strong>L3ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80, ø100, ø12516mm20mm25mmD Double acting<strong>MHS</strong>L 332mm40mm50mm63mm80mm100mm125mmActionDouble actingAction2050How to OrderDF9NAuto switch typeSolid stateD—Auto switch typeGrommetY59AYesNumber of auto switchesNilS2 pcs.1 pc.Nil Without auto switch (bulit-in magnet)Auto switch specificationsAuto switch models Lead wire length (m) ∗Special Electrical Indicator Wiring Load voltageApplicableTypeElectrical entry direction 0.5 3 5function entry light (output)loadsDC AC Perpendicular In-line (Nil) (L) (Z)3 wireF9NV F9N —(NPN)3 wire(PNP)24V—F9PVF9BVWater2 wire 12Vresistant(2 colorindicator)∗ Lead wire length symbols: 0.5m..… Nil (Example) F9B3m…..…L (Example) F9BL5m…..…Z (Example) F9BZD-F9BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.Number of auto switchesNil 2 pcs.S 1 pcn "n" pcs.F9PF9B— F9BA— ——Relay,PLCNil Without auto switch (built-in magnet)Auto switch specificationsTypeSpecial Electrical Indicator Wiring Load voltage Auto switch models Lead wire length (m) ∗ Applicablefunction entry light (output) DC AC In-line Perpendicular 0.5 (Nil) 3 (L) 5 (Z) loads3 wire (NPN)Y69A Y59A IC5V, 12V—3 wire (PNP)Y7PV Y7P circuit2 wire12V Y69B Y59B —Diagnostic3 wire (NPN)Relay,Grommet YesY7NWV Y7NW ICindication24V 5V, 12V —3 wire (PNP)Y7PWV Y7PW circuit PLC(2 colorindicator)Y7BWV Y7BW Waterresistant(2 color2 wire12V— Y7BA — —indicator)Solid state5V,12V∗ Lead wire length symbols: 0.5m ..… Nil (Example) Y59B3m …..… L (Example) Y59BL5m …..… Z (Example) Y59BZD-Y7BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions38

Series <strong>MHS</strong>L3Models and SpecificationsModel<strong>MHS</strong>L3-16D <strong>MHS</strong>L3-20D <strong>MHS</strong>L3-25D <strong>MHS</strong>L3-32D <strong>MHS</strong>L3-40D <strong>MHS</strong>L3-50D <strong>MHS</strong>L3-63D <strong>MHS</strong>L3-80D <strong>MHS</strong>L3-100D <strong>MHS</strong>L3-125DCylinder bore size mm 16 20 25 32 40 50 63 80 100 125FluidAirOperating pressure MPa0.2 to 0.60.1 to 0.6Ambient and fluid temperature °CRepeatability mmMax. operating frequency c.p.m.LubricationAction120-10 to 60±0.0160Non-lubeDouble acting30N at pressure of 0.5MPa forceOpening/closing stroke mm (diameter)Weight gNote 1) ExternalEffective gripping force gripping forceInternalgripping141610802528101354247121807482163701181302055018720428930335359321,550500525402,850750780485,5001,2701,3206411,300Note 1) Values for ø16 to ø25 are with gripping point L = 20mm, for ø32 to ø63 with gripping point L = 30mm, and for ø80 to ø125 with gripping pointL = 50mm.Refer to the "Effective Gripping Force" data on pages 40 through 42 for the gripping force at each gripping position.Note 2) Open and closed diameter values apply for external gripping of work pieces.ConstructionClosed conditionOpen conditionParts listNo. Description1 Body2 Piston3 Cam4 Finger5 Cap6 End plate7 Piston boltMaterialAluminum alloyAluminum alloyCarbon steelCarbon steelAluminum alloyStainless steelStainless steelNoteHard anodizedHard anodizedHeat treated, Specially treatedHeat treated, Specially treatedHard anodizedNo.8910111213DescriptionRubber magnetC type snap ringPiston sealRod sealGasketGasketMaterialSynthetic rubberCarbon steelNBRNBRNBRNBRNoteNickel platedReplacement parts/Seal kitsKit Number<strong>MHS</strong>L3-16D <strong>MHS</strong>L3-20D <strong>MHS</strong>L3-25D <strong>MHS</strong>L3-32D <strong>MHS</strong>L3-40D <strong>MHS</strong>L3-50D <strong>MHS</strong>L3-63D <strong>MHS</strong>L3-80D <strong>MHS</strong>L3-100D <strong>MHS</strong>L3-125DContents<strong>MHS</strong>L16-PS <strong>MHS</strong>L20-PS <strong>MHS</strong>L25-PS <strong>MHS</strong>L32-PS <strong>MHS</strong>L40-PS <strong>MHS</strong>L50-PS <strong>MHS</strong>L63-PS <strong>MHS</strong>L80-PS <strong>MHS</strong>L100-PS <strong>MHS</strong>L125-PSA set of the aboveNos. 10, 11, 12 and 13∗ Seal kits are sets consisting of items 10, 11, 12 and 13, which can be ordered using the kit number for each cylinder bore size.39

Gripping Point• The work piece gripping point distance should be within the gripping forceranges given for each pressure in the effective gripping force graphsbelow.• If operated with the work piece gripping point beyond the indicatedranges, an excessive offset load will be applied to the sliding section ofthe fingers, which can have an adverse effect on the service life of theproduct.Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphsto the right is expressed as F, which is theimpellent force of one finger when all 3 of thefingers and attachments are in full contact with thework piece as shown in the figure below.FExternal gripping force<strong>MHS</strong>L3-16DGripping force N3 Finger Air Gripper Series <strong>MHS</strong>L3LExternal grippingGripping point25 2520 20Pressure 0.6MPa0.5MPa15 150.4MPa10 100.3MPa5 0.2MPa5L<strong>MHS</strong>L3-16DGripping pointInternal grippingL: Gripping point distanceInternal gripping forceGripping force NPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3FExternal grippingFFInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²FF0 5 10 15 20 25 30 0 5 10 15 20 25 30Gripping point L mmGripping point L mm<strong>MHS</strong>L3-20D<strong>MHS</strong>L3-20DGripping force N35Pressure 0.6MPa300.5MPa25200.4MPa150.3MPa100.2MPa40Pressure 0.6MPa350.5MPa30250.4MPa200.3MPa150.2MPa105 50 5 10 15 20 25 30 35 0 5 10 15 20 25 30 35Gripping point L mmGripping point L mm<strong>MHS</strong>L3-25D<strong>MHS</strong>L3-25DGripping force N6070Pressure 0.6MPa605050400.5MPa40300.4MPa30200.3MPa0.2MPa2010 10Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mmGripping force NGripping force NLong stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions40

Series <strong>MHS</strong>L3Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in the graphsto the right is expressed as F, which is theimpellent force of one finger when all 3 of thefingers and attachments are in full contact with thework piece as shown in the figure below.FExternal gripping forceInternal gripping force<strong>MHS</strong>L3-32D<strong>MHS</strong>L3-32DGripping force N100Pressure 0.6MPa800.5MPa600.4MPa0.3MPa400.2MPaGripping force N12010080604020 0.1MPa20Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaFF0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mm<strong>MHS</strong>L3-40D<strong>MHS</strong>L3-40DExternal grippingFGripping force N200 200160 Pressure 0.6MPa160Gripping force N120 0.5MPa1200.4MPa80 0.3MPa800.2MPa400.1MPa40Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaFInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²F<strong>MHS</strong>L3-50D<strong>MHS</strong>L3-50DGripping force N0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mm350 350300 300250Pressure 0.6MPa2502000.5MPa200Gripping force N1500.3MPa0.4MPa1501000.2MPa10050 0.1MPa50Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0 10 20 30 40 50 60 70 0 10 20 30 40 50 60 70Gripping point L mmGripping point L mm<strong>MHS</strong>L3-63D<strong>MHS</strong>L3-63DGripping force N500 500400Pressure 0.6MPa400Gripping force N0.5MPa300 3000.4MPa200 0.3MPa2000.2MPa100 1000.1MPaPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0 20 40 60 80 100 0 20 40 60 80 100Gripping point L mmGripping point L mm41

External gripping forceInternal gripping force<strong>MHS</strong>L3-80D<strong>MHS</strong>L3-80DGripping force N700 700Pressure 0.6MPa6006005000.5MPa0.4MPa4003000.3MPa2000.2MPa1000.1MPa500400300200100<strong>MHS</strong>L3-100D<strong>MHS</strong>L3-100D1,000 1,000Pressure 0.6MPa8008000.5MPa6000.4MPa6004000.3MPa4000.2MPa2000.1MPa200Gripping force N<strong>MHS</strong>L3-125D<strong>MHS</strong>L3-125DGripping force N1,800 1,8001,600Pressure 0.6MPa1,6001,4001,4001,2000.5MPa1,2001,0000.4MPa1,0008000.3MPa8006000.2MPa6004000.1MPa400200200Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0020 40 60 80 20 40 60 80Gripping point L mmGripping point L mmGripping force NPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0020 40 60 80 10020 40 60 80 100Gripping point L mmGripping point L mmGripping force NPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0 20 40 60 80 100 120 0 20 40 60 80 100 120Gripping point L mmGripping point L mmGripping force N3 Finger Air Gripper Series <strong>MHS</strong>L32 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions42

Series <strong>MHS</strong>L3Dimensions<strong>MHS</strong>L3-16D to 25DCB 7P(finger opening port)6-M3 x 0.5, thread depth TB(attachment mounting threads)3-øSA, counter bore dia. SB,counter bore depth SCP.C.D.R (mounting hole)øBCøBBQ O(Open DO)(Closed DC)Open EOClosed ECJK3(AA)ABP(finger closing port)øBAøVA depth VBFX FY FZ22.5 °20 °20 °øWA depth 1.53-UA thread depth 6P.C.D.R(mounting threads)XA depth XBNBNABD2H9 +0.025021HADGNCAuto switch mounting groove positions (2 locations)<strong>MHS</strong>L3-16D <strong>MHS</strong>L3-20D, 25D <strong>MHS</strong>L3-16DMounting hole counter bore dimensions6.1Counter bore depth 5ø4ø454 °34.548 °<strong>MHS</strong>L3-20D33 °3536 °6 (6.5)57.1Counter bore depth 8Dimensions inside ( ) are for ø25Note) The counter bore configuration differs only for themounting hole section between the auto switch mountinggrooves. (ø16 and ø20 only)Model<strong>MHS</strong>L3-16D<strong>MHS</strong>L3-20D<strong>MHS</strong>L3-25DAA43.54649AB40.54346AD282931.5BA303642BB404552BC30.636.642.6BD121619CB141416.5DO23.52630DC18.52124EO13.51416EC8.5910FX12.514.517FY111314.5FZ335G30.53234.2H787.81444.5J101214K456NA81113(mm)NB05h9 -0.03006h9 -0.03006h9 -0.030Model<strong>MHS</strong>L3-16D<strong>MHS</strong>L3-20D<strong>MHS</strong>L3-25DNC577O22.53PM3 x 0.5M5 x 0.8M5 x 0.8Q678R252934SA3.43.44.5SB6.56.58SC588TB566UAM3 x 0.5M3 x 0.5M4 x 0.7VA2H92H93H9+0.0250+0.0250+0.0250VB223WA17H921H926H9+0.0430+0.0520+0.0520XA2H92H93H9+0.0250+0.0250+0.0250XB22343

<strong>MHS</strong>L3-32D to 80DCB3 Finger Air Gripper Series <strong>MHS</strong>L3CAP(finger opening port)2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>33-øSA, counter bore dia. SB, counter bore depth SCP.C.D.R (mounting hole)6-TA thread depth TBAttachment mounting threadsøBCAC(AA)ABP(finger closing port)øVA depth VBøWA depth WB22.5°20°20°3-UA depth UBP.C.D.R (mounting threads)With dust cover<strong>MHS</strong>J3øBBNBNABDQ O(Open DO)(Closed DC)JOpen EOClosed ECKLMIHADGøBAFXFY FZNCXA depth XBThrough hole<strong>MHS</strong>H3Auto switch mounting groove positions (4 locations)Mounting hole counter bore dimensions<strong>MHS</strong>L3-32DLong stroke<strong>MHS</strong>L310°10°6.4Model<strong>MHS</strong>L3-32D<strong>MHS</strong>L3-40D<strong>MHS</strong>L3-50D<strong>MHS</strong>L3-63D<strong>MHS</strong>L3-80DModel<strong>MHS</strong>L3-32D<strong>MHS</strong>L3-40D<strong>MHS</strong>L3-50D<strong>MHS</strong>L3-63D<strong>MHS</strong>L3-80DModel<strong>MHS</strong>L3-32D<strong>MHS</strong>L3-40D<strong>MHS</strong>L3-50D<strong>MHS</strong>L3-63D<strong>MHS</strong>L3-80D40°5Auto switch mounting groove positionsAA586477.589116L2H93H94H96H98H9AB556174.585111+0.0250+0.0250+0.0300+0.0360+0.0360WA34H942H952H965H982H9+0.0620+0.0620+0.0740+0.0740+0.0870YM22234AC33345WB2222.53AD35.538.546.55170NA1618202630XA3H94H94H95H96H9BA52627086106NB08h9 –0.03608h9 –0.036010h9 –0.036012h9 –0.043014h9 –0.043+0.0250+0.0300+0.0300+0.0300+0.0300XB3445640°BB7282104120140NC1010121416Y6877.59BC52.662.670.686.6106.6O4.54.555.56BD2430324050CA8991214PM5 x 0.8M5 x 0.8M5 x 0.8M5 x 0.8Rc 1/8CB20222930.537.5Q11121417208.3 counter bore depth 8(2 positions)DO4247.5607080.5R4453627695DC3437.5465460.5SA4.55.55.56.66.6R7Note) The counter bore configuration differs only for themounting hole section between the auto switch mountinggrooves. (ø32 only)EO2226.5364248.5SB89.59.51111EC1416.5222628.5SC89.59.51723FX2226.5313847.5TAM4 x 0.7M4 x 0.7M5 x 0.8M5 x 0.8M6 x 1FY19.523.52834.543.5TB88101012FZ56678G39.642.551.358.578.5UAM4 x 0.7M5 x 0.8M5 x 0.8M6 x 1M6 x 1H10.413.517.719.523.5UB61010121215781011VA3H94H94H95H96H9J2021242832+0.0250+0.0300+0.0300+0.0300+0.0300(mm)K99101112VB34456444 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions

15Series <strong>MHS</strong>L3Dimensions<strong>MHS</strong>L3-100D, 125DCBCAP(finger opening port)P(finger closing port)3-øSA, counter bore dia. SB, counter bore depth SCP.C.D.R (mounting hole)6-TA thread depth TB(attachment mounting threads)AC(AA)ABøVA depth VB22.5°20°20°øWA depth WBøBBøBCQ O(Open DO)(Closed DC)LJKOpen EOClosed ECøBAFXXA depth XBFY FZNBNABDMIHADG3-UA thread depth 6 UBP.C.D.R (mounting threads)<strong>MHS</strong>L3-100D<strong>MHS</strong>L3-125D10°10°10°10°40°40°40°40°6.4590°10136.45512790°Model<strong>MHS</strong>L3-100D<strong>MHS</strong>L3-125DAA135175AB129167AC68AD78102BA134166BB184234BC134.6166.6BD5666CA1824CB44.554DO103132DC79100EO6580EC4148FX5974FY5468FZ1012G86112H3143I1417J3852(mm)K1521Model<strong>MHS</strong>L3-100D<strong>MHS</strong>L3-125DL8H910H9+0.0360+0.0360M46NA3743NB018h9 -0.043022h9 -0.052NC2125O7.510.5PRc 1/4Rc 3/8Q2331R118148SA911SB1417.5SC3132TAM8 x 1.25M10 x 1.5TB1620UAM8 x 1.25M10 x 1.5UB1620VA8H910H9+0.0360+0.0360Model<strong>MHS</strong>L3-100D<strong>MHS</strong>L3-125DVB68WA102H9130H9+0.0870+0.1000WB46XA8H910H9+0.0360+0.0360XB6845

4 FingerAir GripperParallel TypeCylinder Bore Sizeø16 to ø25Cylinder Bore Sizeø32 to ø63Symbol<strong>MHS</strong> 4Number of fingers4 4 fingersCylinder bore size162025Number of fingers4 4 fingersCylinder bore size16mm20mm25mm<strong>MHS</strong> 432405063Series <strong>MHS</strong>4ø16, ø20, ø25, ø32, ø40, ø50, ø63ActionD Double acting32mm40mm50mm63mmActionD Double acting2050How to OrderDF9NNumber of auto switchesNilSAuto switch typeNil Without auto switch (bulit-in magnet)Auto switch specificationsTypeSolid stateDSpecialfunction—Waterresistant(2 colorindicator)Auto switch typeElectricalentryGrommetY59AIndicatorlightYesWiring(output)3 wire(NPN)3 wire(PNP)2 wire2 pcs.1 pc.Auto switch models Lead wire length (m) ∗ Load voltageElectrical entry directionApplicable0.5 3 5loadsDC AC Perpendicular In-line (Nil) (L) (Z)F9NV F9N —5V,12VF9PV F9P —Relay,24V —PLCF9BV F9B —12V— F9BA — Number of auto switchesNil 2 pcs.S 1 pcNil Without auto switch (built-in magnet)Auto switch specificationsSpecial Electrical Indicator Wiring Load voltage Auto switch models Lead wire length (m)Type∗ Applicablefunction entry light (output) DC AC In-line Perpendicular 0.5 (Nil) 3 (L) 5 (Z) loads3 wire (NPN)Y69A Y59A IC—5V, 12V3 wire (PNP)Y7PV Y7P circuit2 wire 12V Y69B Y59B —Diagnostic3 wire (NPN)Y7NWV Y7NW IC Relay,indication Grommet Yes24V 5V, 12V —3 wire (PNP)Y7PWV Y7PW circuit PLC(2 colorindicator)Y7BWV Y7BW Water resistant2 wire12V—(2 color indicator)— Y7BA — Solid state∗ Lead wire length symbols: 0.5m ..... Nil (Example) F9B3m ........ L (Example) F9BL5m ........ Z (Example) F9BZD-F9BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selection∗ Lead wire length symbols: 0.5m ..… Nil (Example) Y59B3m…..… L (Example) Y59BL5m…..… Z (Example) Y59BZD-Y7BA is available only as "L".∗ Auto switches marked with a "" symbol are produced upon receipt of order.Note 1) Take note of hysteresis with 2 color indication type switches.Note 2) Refer to pages 53 through 65 for detailed auto switch specifications.Precautions46

Series <strong>MHS</strong>4Models and SpecificationsModelCylinder bore size mmFluidOperating pressure MPaAmbient and fluid temperature °CRepeatability mmMax. operating frequency c.p.m.LubricationActionEffectiveNote 1)External gripping forcegripping force N atpressure of 0.5MPa Internal gripping forceOpening/closing stroke mmWeight g<strong>MHS</strong>4-16D <strong>MHS</strong>4-20D <strong>MHS</strong>4-25D <strong>MHS</strong>4-32D <strong>MHS</strong>4-40D <strong>MHS</strong>4-50D <strong>MHS</strong>4-63D16 20 25 32 40 50 6310124660.2 to 0.61201921411031356154Air–10 to 60±0.01Non-lubeDouble acting55618300Note) Values for ø16 to ø25 are with gripping point L = 20mm, and for ø32 to ø63 with gripping point L = 30mm.Refer to the "Effective Gripping Force" data for the gripping force at each gripping position.889783900.1 to 0.66014015312590251268161,095ConstructionClosed conditionOpen conditionParts listNo.1234567DescriptionBodyPistonCamFingerCapEnd platePiston boltMaterialAluminum alloyAluminum alloyCarbon steelCarbon steelAluminum alloyStainless steelStainless steelNoteHard anodizedHard anodizedHeat treated, Specially treatedHeat treated, Specially treatedHard anodizedNo.8910111213DescriptionRubber magnetC type snap ringPiston sealRod sealGasketGasketMaterialSynthetic rubberCarbon steelNBRNBRNBRNBRNoteNickel platedReplacement parts/Seal kits<strong>MHS</strong>4-16D <strong>MHS</strong>4-20D <strong>MHS</strong>4-25DKit number<strong>MHS</strong>4-32D <strong>MHS</strong>4-40D <strong>MHS</strong>4-50D <strong>MHS</strong>4-63DContents<strong>MHS</strong>16-PS <strong>MHS</strong>20-PS <strong>MHS</strong>25-PS <strong>MHS</strong>32-PS <strong>MHS</strong>40-PS <strong>MHS</strong>50-PS <strong>MHS</strong>63-PSA set of the aboveNos. 10, 11, 12 and 13∗ Seal kits are sets consisting of items 10, 11, 12 and 13, which can be ordered using the kit number for each cylinder bore size.47

Gripping Point• The work piece gripping point distance should be within the grippingforce ranges given for each pressure in the effective gripping forcegraphs below.• If operated with the work piece gripping point beyond the indicatedranges, an excessive offset load will be applied to the sliding section ofthe fingers, which can have an adverse effect on the service life of theproduct.Internal grippingL: Gripping point distanceExternal gripping forceInternal gripping force<strong>MHS</strong>4-16D<strong>MHS</strong>4-16D15Pressure 0.6MPa15100.5MPa100.4MPa0.3MPa50.2MPa50 5 10 15 0 5 10 15Gripping point L mmF<strong>MHS</strong>4-20D<strong>MHS</strong>4-20DF30Pressure 0.6MPa30FF200.5MPa200.4MPa100.3MPa100.2MPaExternal gripping0 10 20 0 10 20FGripping point L mm<strong>MHS</strong>4-25D<strong>MHS</strong>4-25D5050F40Pressure 0.6MPa400.5MPa30300.4MPa200.3MPa20FInternal gripping0.2MPa10 100 10 20 0 10 201N: Approx. 0.102kgfGripping point L mmEffective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in thegraphs to the right is expressed as F, whichis the impellent force of one finger when allfour of the fingers and attachments are infull contact with the work piece as shown inthe figure below. If only one of the two pairsof opposing fingers are used for grippingwork pieces, while the other pair is used foranother function such as positioning, thegripping force of the Series <strong>MHS</strong>4 will bethe same as that of the Series <strong>MHS</strong>2.FGripping force NGripping force NGripping force N4 Finger Air Gripper Series <strong>MHS</strong>4LGripping pointGripping force N20 25 30 20 25 30Gripping force NGripping point L mm30 40 30 40Gripping force NGripping point0.5MPa0.4MPa0.5MPa0.4MPaGripping point L mm0.5MPa0.4MPa0.3MPa0.3MPa30 40 30 40LPressure 0.6MPaGripping point L mm0.2MPaPressure 0.6MPa0.2MPaPressure 0.6MPa0.3MPa0.2MPa2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3Long stroke<strong>MHS</strong>L34 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions48

Series <strong>MHS</strong>4Effective Gripping Force• Expressing the effective gripping forceThe effective gripping force shown in thegraphs to the right is expressed as F, whichis the impellent force of one finger when allfour of the fingers and attachments are in fullcontact with the work piece as shown in thefigure below. If only one of the two pairs ofopposing fingers are used for gripping workpieces, while the other pair is used foranother function such as positioning, thegripping force of the Series <strong>MHS</strong>4 will be thesame as that of the Series <strong>MHS</strong>2.External gripping forceInternal gripping force<strong>MHS</strong>4-32D<strong>MHS</strong>4-32DGripping force N75Pressure 0.6MPa600.5MPa450.4MPa0.3MPa300.2MPaGripping force N7560453015 0.1MPa15Pressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaFFFFExternal grippingF<strong>MHS</strong>4-40D<strong>MHS</strong>4-40DGripping force N010 20 30 40 50010 20 30 40 50Gripping point L mmGripping point L mm125Pressure 0.6MPa1000.5MPa750.4MPa0.3MPa500.2MPa125100755025 250.1MPa0 10 20 30 40 50 0 10 20 30 40 50Gripping point L mmGripping point L mmGripping force NPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPaFFInternal gripping1N: Approx. 0.102kgf1MPa: Approx. 10.2kgf/cm²F<strong>MHS</strong>4-50D<strong>MHS</strong>4-50DGripping force N200200Pressure 0.6MPaPressure 0.6MPa150 1500.5MPa1000.4MPa1000.3MPa020 40 60 0 20 40 60Gripping point L mmGripping point L mmGripping force N500.2MPa500.1MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa<strong>MHS</strong>4-63D<strong>MHS</strong>4-63DGripping force NPressure 0.6MPa300 3000.5MPaGripping force N200 0.4MPa2000.3MPa0.2MPa100 1000.1MPaPressure 0.6MPa0.5MPa0.4MPa0.3MPa0.2MPa0.1MPa0 020 40 60 20 40 60Gripping point L mmGripping point L mm49

XA, depth XB4 Finger Air Gripper Series <strong>MHS</strong>4Dimensions<strong>MHS</strong>4-16D to 25D2-ø3.4, counter bore dia. 6.5Counter bore depth SC (mounting hole)RA3AAABøWA, depth 1.5RAøVA depth VB2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>3RBO(Open DO)(Closed DC)QNBNA8-M3 x 0.5, thread depth TBAttachment mounting threadsCB 7øBFZP(finger opening port)20°FY20°FXRB2-M4 x 0.7, thread depth 8(mounting threads)With dust cover<strong>MHS</strong>J3Through hole<strong>MHS</strong>H3JOpen EOClosed ECK2H9 +0.02502IGP(finger closing port)Long stroke<strong>MHS</strong>L3Auto switch mounting groove positions (2 locations)4.5<strong>MHS</strong>4-16D <strong>MHS</strong>4-20D <strong>MHS</strong>4-25D324°ø4ø433°655324°33°6.5553ø424°33°4 finger <strong>MHS</strong>4 Auto switchesModel<strong>MHS</strong>4-16D<strong>MHS</strong>4-20D<strong>MHS</strong>4-25DModel<strong>MHS</strong>4-16D<strong>MHS</strong>4-20D<strong>MHS</strong>4-25DAA353840RA182426AB323537RB161822B303642SC89.510CB111315TB566DC333948VA2H92H93H9DO374354+0.0250+0.0250+0.0250EC131520VB223EO171926WA17H921H926H9FX12.514.517+0.0430+0.0520+0.0520FY111314.5XA2H92H93H9+0.0250+0.0250+0.0250FZ335XB223G252728I455J101214K456NA81012NB05h9 -0.03006h9 -0.03006h9 -0.030O22.53PM3 x 0.5M5 x 0.8M5 x 0.8(mm)Q678Model selectionPrecautions50

XA, depth XBSeries <strong>MHS</strong>4Dimensions<strong>MHS</strong>4-32D, 40D2-øSA, counter bore dia. SBCounter bore depth 9 (mounting hole)RA3AAAB6.435°RA35°5øVA, depth VB8øB4.5(Open DO)(Closed DC)QCBCAM5 x 0.8(finger opening port)LJ9Open EOClosed EC8h9 -0.0360RBNARBFZ20°FY20°FX2-UA, thread depth UB(mounting threads)øWA, depth 28-M4 x 0.7, thread depth 8Attachment mounting threadsIGM5 x 0.8(finger closing port)2Model<strong>MHS</strong>4-32D<strong>MHS</strong>4-40DAA4447AB4144B5662CA89CB1617DC6066DO6874EC2024EO2832FX2326.5FY20.523.5FZ56G30.532I67J2021L2H93H9+0.0250+0.0250NA1416Q1112RA3844RB2528(mm)SA4.55.5Model<strong>MHS</strong>4-32D<strong>MHS</strong>4-40DSB89.5UAM5 x 0.8M6 x 1UB1012VA3H94H9+0.0250+0.0300VB34WA34H942H9+0.0620+0.0620XA3H94H9+0.0250+0.0300XB3451

XA, depth XB4 Finger Air Gripper Series <strong>MHS</strong>4<strong>MHS</strong>4-50D, 63D4-ø5.1, counter bore dia. 9.5Counter bore depth SC (mounting hole)RAACAAAB6.435°RA35°2 finger <strong>MHS</strong>2 3 finger <strong>MHS</strong>35RBNAøBYCøVA, depth VBRBWith dust cover<strong>MHS</strong>J3NBO(Open DO)(Closed DC)QFZFY20°20°FX4-M6 x 1, thread depth 12(mounting threads)øWA, depth WBThrough hole<strong>MHS</strong>H38-M5 x 0.8, thread depth 10Attachment mounting threadsCBCAM5 x 0.8(finger opening port)Long stroke<strong>MHS</strong>L3Model<strong>MHS</strong>4-50D<strong>MHS</strong>4-63DModel<strong>MHS</strong>4-50D<strong>MHS</strong>4-63DAA5566O55.5AB5262Q1417AC34RA5266JB7086RB3438Open EOClosed ECKLCA912SC1214CB2022VA4H95H9DC7491+0.0300+0.0300MIDO86107VB45GEC2635WA52H965H9EO3851+0.0740+0.0740FX3138WB22.5M5 x 0.8(finger closing port)FY2834.5XA4H95H9+0.0300+0.0300FZ67XB45G37.544YC77.5I911J2428K1011L4H96H9+0.0300+0.0300M23NA1824(mm)NB010h9 -0.036012h9 -0.0434 finger <strong>MHS</strong>4 Auto switchesModel selectionPrecautions52