EX500-GPR1

EX500-GPR1

EX500-GPR1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Reduced wiring systemPROFIBUS-DP Compatible GW UnitInstruction Manual<strong>EX500</strong>-<strong>GPR1</strong>AURL http://www.smcworld.com

ContentsThank you for purchasing the SMC reduced wiring system <strong>EX500</strong> series.Please read this instruction manual carefully and understand the contents beforeuse so that you can operate this unit safely and correctly.Please keep this manual handy for future reference.OPERATORThis instruction manual has been written for those who have knowledge ofmachines and equipments that use reduced wiring system as well as thesufficient knowledge to assemble, operate, and maintain such devices.Before performing assembly, operation and/or maintenance, please readthis manual carefully and understand the contents.SAFETY ..........................................................................................................2Product Summary............................................................................................5<strong>EX500</strong>Part Names ...................................................................................................6Dimensions ...................................................................................................7Installation.....................................................................................................7Specification..................................................................................................8Wiring..........................................................................................................10Display/Switch setting .................................................................................17SI UnitPart Names .................................................................................................20Dimensions .................................................................................................21Mounting/Wiring ..........................................................................................22Specification................................................................................................23Display ........................................................................................................24Input Unit ManifoldPart Names .................................................................................................25Dimensions .................................................................................................26Installation...................................................................................................27Specification................................................................................................28Wiring..........................................................................................................29Display ........................................................................................................30EX9 Series General Purpose Output BlockPart Names .................................................................................................31Dimensions .................................................................................................32Mounting .....................................................................................................33Wiring..........................................................................................................34Specification................................................................................................36Display .......................................................................................................37Option............................................................................................................38Troubleshooting.............................................................................................39Appendix Table .............................................................................................40

SAFETYThe body of unit and this manual contain the essential information for the protection ofusers and others from possible injury and property damage and to ensure correcthandling.Please check that you fully understand the definitions of the following messages( symbols ) before going on to read the body of this manual, and always follow theinstructions.Please also read the instruction manuals etc. of related machines and equipments andunderstand the contents before use.IMPORTANT MESSAGESRead this manual and follow its instructions. Signal words such as WARNING,CAUTION and NOTE will be followed by important safety information that must becarefully reviewed.Indicates a potentially hazardous situation that could result indeath or severe injury if you do not follow instructions.NOTEIndicates a potentially hazardous situation that, if not avoided,may result in minor injury or moderate injury.Gives you helpful information.Do not disassemble,modify ( including modification of printed circuit board ) or repair.Otherwise injury or failure can result.Do not operate beyond specification range.Otherwise fire, malfunction or damage to the reduced wiring system can result.Confirm the specifications before operation.Do not operate in atmosphere of flammable/explosive/corrosive gas.Otherwise fire, explosion or corrosion can result.This reduced wiring system is not explosion-proof type.For use in interlock circuit:Provide double interlock system by adding different type of protection( such as mechanical protection ).Check that the interlock circuit is working normally.Otherwise accident caused by malfunction can result.Before performing maintenance:Turn off power supply.Stop air supply, exhaust compressed air in piping, and confirm the releaseto atmosphere.Otherwise injury can result.Conduct proper functional inspection after completing maintenance.In the case of abnormality such as unit does not work normally, stop the operation.Otherwise safety cannot be assured due to unintended malfunction.Provide grounding to improve safety and noise resistance of reduced wiringsystem.Provide grounding as close to the unit as possible to shorten distance for grounding.Handling precautionsUse the following UL-recognized DC power supply to combine with.1. UL508-compatible limited voltage/current circuitA circuit using the secondary coil of an insulating transformer that meets following conditionsas power source.Maximum voltage ( at no load ): 30Vrms ( 42.4Vpeak ) or belowMaximum current: ( 1 ) 8A or less ( including when short-circuited )( 2 ) When limited by the circuit protector ( such as fuse )having the following rating.No-Load Voltage ( Vpeak ) Max. Current Rating ( A )0 to 20 [V] 5.0Above 20 [V] to 30 [V] 100/peak voltage2. UL1310-compatible Class 2 power supply unit or circuit of max. 30Vrms ( 42.4Vpeak ) or lessusing a UL1585-compatible Class 2 transformer as power source. ( Class 2 circuit )2 3

SAFETY ( continued )Follow the instructions given below when handling your reduced wiring system.Otherwise a damage or failure to cause a malfunction can result.Operate the reduced wiring system at the specified voltage.Reserve space for maintenance.Do not remove any name plate or label.Do not drop, hit or apply an excessive shock to the unit.Follow the specified tightening torque.Do not apply any excessive force to cables by repeated bending, tensioning or placing aheavy object on the cables.Connect wires and cables correctly.Do not perform any wiring work while the power is on.Do not use the reduced wiring system on the same wiring route as the power line or highvoltage line.Confirm the insulation of wiring.Perform the power supply wiring by dividing into two lines ---- one is for power supply for outputand the other is for power supply for input and controlling GW/SI.Take sufficient measures against noise such as noise filter when incorporating the reducedwiring system into a machine or equipment.Mount a terminal plug or a waterproof cap on each unused M12 connector for input/output( communication connector, communication ports A - D, and power supply for input andcontrolling GW/SI ).Take sufficient shielding measures when operating the product in any of the following places.( 1 ) A place where noise due to static electricity etc. is generated( 2 ) A place of high electric field strength( 3 ) A place where exposure to radioactivity is possible( 4 ) A place near power cableDo not operate the product in a place where there is a source of surge.Use a surge absorbing element built-in type to directly drive the load that generates surgevoltage such as solenoid valve.Prevent any foreign matter such as remnant of wires from getting inside the product whenopening the station number switch protective cover.Install the reduced wiring system in a place free from vibration and impact.Operate the product in the specified ambient temperature range.Do not use in a place to be affected by the radiant heat from a surrounding heat source.Set the DIP switch and rotary switch by using a sharp-pointed watchmakers screwdriver etc.Perform the maintenance regularly.Conduct an appropriate functional inspection after completing the maintenance.Do not use chemicals such as benzin and thinner to clean the product.Product SummarySystem configurationPROFIBUS-DPcommunication connectorPower supplyconnector cable( DC24V for solenoidvalves/output, DC24V forinput and controlling GW/SI )Manifold valvewith SI unit( SV/VQC series )Branch cablewith M12 connectorGW unitInput unit manifoldManifold valvewith SI unit( SV/VQC series )Input unitmanifoldBranch cablewith M12 connectorThe reduced wiring system is connected to various kinds of fieldbus realizes thereduced wiring and decentralized installation of I/O devices . The signals to/fromfieldbus are exchanged by GW unit, and the signals to/from decentralized I/O devicesare collected and delivered by GW unit.The maximum number of connections of manifold valve/Input unit manifold is16/branch x 4 branches = 64 points each for output and input.As the cables with connectors are used for all wirings among devices, the systemcomplies with the IP65 environment.4 5

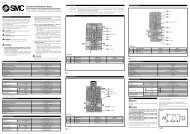

<strong>EX500</strong>-<strong>GPR1</strong><strong>EX500</strong> Part NamesDimensions ( unit: mm )<strong>EX500</strong> bodyOUTBUSINDIABFSOLRUNINOUTBUSRUNSOLBFDIAGATEWAY UNIT<strong>EX500</strong> SERIESPE88<strong>EX500</strong>-<strong>GPR1</strong>A24VDCCOM ACOM BCOM CCOM D1601364649.9No.1NameCommunicationconnectorApplicationConnect with PROFIBUS-DP line. ( Note 1 )10234567Power supply connectorCommunication port A( COM A )Communication port B( COM B )Communication port C( COM C )Communication port D( COM D )DisplaySupply power for output devices such as solenoidvalve, for input devices such as sensor, and forcontrolling GW/SI by using power supply connectorcable. ( Note1 )Connect SI unit ( manifold valve ) or Input unit byusing branch cable with M12 connectors. ( Note1 )Display the power supply status and communicationstatus with PLC. ( Note2 )Installation ( unit: mm )Thread mountingSecure at four positions with screws with head diameter of 5.2 or more and threadlength of 15mm or more.4 M5Tightening torque :*(1.5 0.2 ) Nm14868 58Station number switchprotective coverSet address and bus terminator by using theswitches under this cover. ( Note2 )Cutout Dimensions for Mounting (Tolerance: 0.2)Note1: For wiring method, refer to subsection "Wiring" ( page 10 ) of section "<strong>EX500</strong>" in thismanual.Note2: For display and setting method, refer to subsection "Display/Switch Setting" ( page 17 )of section "<strong>EX500</strong>" in this manual.6 7

SpecificationBasic specificationsRated voltageRange of powersupply voltageDC24VPower supply for input and controlling GW/SI: DC24V 10%Power supply for output: DC24V+10%/-5% ( Voltage dropwarning at around 20V )Rated current Power supply for input and controlling GW/SI: 3.0AInside GW unit: 0.2A( Input device and SI control section: 2.8A )Power supply for solenoid valves and output: 3ANumber of input/ Input point: max. 64/Output point: max 64output pointsHigher-level busProtocol PROFIBUS-DP ( EN50170 )Bus interfaceEIA RS-485Transmission rateTransmission distance9.6/19.2/45.45/93.75/187.5/500kbps, 1.5/3/6/12MbpsRefer to the following.Freeze mode/Sync mode SupportedID Number 1405 ( hexadecimal )Lower-level busNumber of branches forinput/outputCommunication methodBranch current for input( Note )Branch current for outputBranch cable length4 branches ( 16 points/branch ) for input4 branches ( 16 points/branch ) for outputProtocol: Dedicated for SMCSpeed: 750kbpsMax. 0.5 [A] per branch ( when SI unit and inputdevices are connected )Max. 0.65 [A] per branch( when SI unit <strong>EX500</strong>-S 01 is connected )Max. 0.75 [A] per branch( when SI unit <strong>EX500</strong>-Q )is connected )5m or less per branch( total extended length: 10m or less )Note: Total value of maximum current consumption and maximum load current of input devicesto connect.Transmission distanceFor the communication wiring, use a PROFIBUS-DP compatible twisted pair cable withshield. The maximum cable length depends on the transmission rate and the cable typeto use. The following table shows the values when cable Type A ( see Note ) is used.Transmissionrate [kbps]9.6 19.2 45.45 93.75 187.5 500 1500 3000 6000 12000Cable length [m] 1200 1000 400 200 100Note: Cable Type A specificationImpedance 135 - 165Capacity30pF/m or lessLoop resistance 110 /kmWire diameterCorecross-section0.64mm or more0.34mm 2 ormore8 9

WiringInternal circuitPowersupplyconnectorCommunicationconnectorPower supplyfor outputPower supplyfor input andcontrolling GW/SIN.C. 1RxD/TxD(N) 2N.C. 3RxD/TxD(P) 4Shield 5N.C. 1RxD/TxD(N) 2N.C. 3RxD/TxD(P) 4Shield 50V 1+24V 20V 3+24V 4PE 5DC-DCconverter(insulation)Internal circuit1 RD+2 RD -3 TD+4 TD -5 +24V6 0V7 +24V8 0V1 RD+2 RD -3 TD+4 TD -5 +24V6 0V7 +24V8 0VCOM ACOM DCommunication wiringConnect the cable with PROFIBUS-DP communication connector to the communicationconnector of GW unit.Cable connectionAligning the key groove with the IN-sidecommunication connector ( 5-pin, plug ) of2GW unit, plug the PROFIBUS-DP communicationcable ( socket ).3Tighten the lock nut on cable side by turning itclockwise by hand.Confirm that the connector portion does not move.Similar to the above, connect the other communicationcable ( plug ) to the OUT-side communicationconnector ( 5-pin, socket ) of GW unit.Connection of bus terminator5IN14145OUTIN23The wirings are described in the following order.Communication wiring: Connection with PROFIBUS-DPTo the units at both ends of PROFIBUS-DP system,be sure to connect "bus terminators".If this <strong>EX500</strong> is such end unit, set the bus terminator.( For how to set, refer to subsection "Display/SwitchSetting" ( page 17 ) of section "<strong>EX500</strong>" in this manual. )Data lineData lineVP390RxD/TxD-P220RxD/TxD-N390DGNDPin layout and connection diagram of cable with PROFIBUS-DP communication connectorConnect the communication cable with M12 connector to the M12 reversecommunication connector. For the cable to use, refer to "Appendix Table" ( page 40 ) inthis manual.M12Power supply wiring: Connections of power supplies forsolenoid valves/output devices, andfor input devices and controlling GW/SIBranch wiring: Connection from GW unit to SI unit or Input unit10 1114.9Common to IN side and OUT sidePin No.1Cable color: Signal nameN.C.: N.C.2 Green: RxD/TxD(N)3 N.C.: N.C.Pin No.Cable color: Signal name4 Red: RxD/TxD(P)5 SHIELD: Shield

Wiring ( continued )Power supply wiringConnect the power supply connector cable to the power supply connector of GW unit.There are two types of cables different in connector shape ---- straight type and angletype. With this cable, the power is supplied to the output devices such as solenoid valve,and the input devices such as sensor, and for controlling GW/SI. Therefore, there is noneed to supply the power to other units individually.When selecting the power supply, refer to "Handling precautions" ( page 3 ) in this manual.Cable connectionAligning the key groove with the power supplyconnector ( plug ) of GW unit, plug the power supplycable ( socket ).Tighten the lock nut on cable side by turning itclockwise by hand.Confirm that the connector portion does not move.Separate wiring for power supply for solenoid valves/output andfor input and control of GW/SIBoth single power supply and two power supply systems can be adopted, however, thewiring shall be made separately ( for solenoid valves/output and for input and controllingGW/SI ) for either system.A. Two power supply system24VDC24VDCBrown: 0V ( for solenoid valves/output )White: DC24V ( for solenoid valves/output )Gray: Ground ( PE )Blue: 0V ( for input and controlling GW/SI )Black: DC24V ( for input and controlling GW/SI )Cable Part No. : <strong>EX500</strong>-AP -2513 4Power supplyconnectorPin layout and connection diagram of power supply connector cable for ( unit: mm )( Pin layout and connection diagram are common to all cables. )M1214.91834486M1230 550 31.3Straight connector TypeAngle connector Type<strong>EX500</strong>-AP -S <strong>EX500</strong>-AP -A28.3630 550B. Single power supply systemBrown: 0V ( for solenoid valves/output )White: DC24V ( for solenoid valves/output )Gray: Ground ( PE )24VDCBlue: 0V ( for input and controlling GW/SI )Black: DC24V ( for input and controlling GW/SI )Cable Part No. : <strong>EX500</strong>-AP -2513 4Power supplyconnectorPin No.12345Cable color: Signal nameBrown: 0V ( for solenoid valves/output )White: DC24V+10%/-5% ( for solenoid valves/output )Blue: 0V ( for input and controlling GW/SI )Black: DC24V 10% ( power supply for input and controlling GW/SI )Gray: Ground ( PE )1254 3Socket Connector Pin LayoutNOTEConnect a ground cable of 100 or less to PE terminal.( The Shield and PE terminal of PROFIBUS-DP are connected inside GW unitthrough capacitor. )12 13

Wiring ( continued )Branch wiring ( wiring to communication ports )For wiring with solenoid valves or input devices, connect the branch cable with M12connector to communication ports A - D.There are two types of cables different in connector shape ---- straight type and angletype. As each cable contains power supply wire, there is no need to supply the power tosolenoid valves or input devices individually.Cable connectionFor GW unit – Manifold valve – Input unit manifold configurationTwo communication connectors in SI unit and one communication connector in Inputunit are installed respectively.To the communication connector ( C2 ) or ( 1 ) of SI unit, connect the branch cable withM12 connector from GW. To the communication connector ( C1 ) or ( 0 ), connect thebranch cable with M12 connector from Input unit.To the communication connector of Input unit, connect the branch cable with M12connector from SI unit.Aligning the key groove with theconnector ( socket ) of GW unit, plug inthe cable ( plug ). 1 28 82 17337GW unitManifold valve with SI unit(for SV/VQC series)Connector (C1) / (0)6446Connector (C2) / (1)5Socket Connector Pin Layout5Plug Connector Pin LayoutTighten the lock nut on cable side byturning it clockwise by hand.Confirm that the connector portion doesnot move.Branch cablewith M12 connectorInput unit manifoldNOTEMount a waterproof cap on each unused connector of GW unit. The proper use ofwaterproof cap can achieve IP65 Enclosure. ( Tightening torque: 0.1Nm for M12 )NOTEWhen no Input unit is connectedto the connector ( C1 ) or ( 0 ) ofSI unit, mount a terminal plug onthe connector.Manifold valve with SI unit( for SV/VQC series )Terminal plug14 15

RWiring (continued )For GW unit – Input unit manifold configurationDisplay/Switch SettingSettings for displayTo the communication connector of Input unit, connect the branch cable with M12connector from GW unit.GW unitP R O F IINB U SBUSOUTRUNSOLBFDIAGATEWAY UNIT<strong>EX500</strong> SERIESCOM A COM B COM C COM DBranch cablewith M12 connectorInput unit manifoldType, pin layout and connection diagram of the branch cable with M12 connector ( <strong>EX500</strong>-AC - )M1248L65216DisplayRUNSOLBFDIACOM ALights on: Power for Input and controlling GW/SI is supplied.Lights off: Power for Input and controlling GW/SI is not supplied.Lights on: Power is supplied to solenoid valves/output at specified voltage.Lights off: Power is not supplied to solenoid valves/output at specifiedvoltage.( Voltage dropped to lower than 20V )Lights on: PROFIBUS-DP communication is abnormal.Lights off: PROFIBUS-DP communication is normal.Lights on: DIA is abnormal.Lights off: DIA is normal.DescriptionLights on: COM A is receiving data.Lights off: COM A has no received data.14.9Straight Connector Type<strong>EX500</strong>-AC-SSPSM12COM BCOM CLights on: COM B is receiving data.Lights off: COM B has no received data.Lights on: COM C is receiving data.Lights off: COM C has no received data.M12M12COM DLights on: COM D is receiving data.Lights off: COM D has no received data.28.331.3631.332.3NOTEWhen connecting manifold valve only without connecting Input unit manifold, LEDs ofCOM A - D do not light. To make them light, connect a terminal plug to the unusedconnector of SI unit ( "C1" or "0" ).LAngle Connector Type<strong>EX500</strong>-AC -SAPAL=300, 500, 1000, 3000, 5000 (mm)16 17

Display/Switch Setting (continued )Switch settingOpen the station number switch protective cover and set the switches with asharp-pointed watchmakers screwdriver etc.NOTE1. Be sure to turn off the power before setting the switches.2. Be sure to set these switches before use. The factory default settings are all "OFF"or "0".3. After opening and closing the station number switch protective cover, tighten thescrews by proper tightening torque. ( Tightening torque: 0.6Nm )Address setting switches 1, 2 and 3 ( SW1, SW2 and SW3 )These switches can set the node address. The settings of each switch are as shown inthe table below. The addresses up to 32 stations ( without repeater ) or 126 stations( with repeater ) can be set per segment.ONOFF1 2SW3x100987605SW21234x10987605SW11234x1SW4ONOFF1 2SW3987605SW21234987605SW11234ONOFF1N.CSW3210SW20 ... 9SW10 ... 9Bus terminator switch ( SW4 )This switch can set the bus terminator.Withbus terminatorWithoutbus terminatorWithoutbus terminatorON OFF OFFON OFF OFFON OFF OFF18 19

SI Unit Part Names Dimensions ( unit: mm )The SI unit is the unit to communicate with GW unit in combination with manifold valve.It can be used with SV series valves and VQC series valves.In addition, this unit is able to operate solenoid valves, relays. etc. in combination withEX9 series general purpose output block. For how to use it, refer to section "EX9 SeriesGeneral Purpose Output Block" ( page 31 ) in this manual.1. SI unit for SV series valves ( <strong>EX500</strong>-S 01 )1. SI unit for SV series valves ( <strong>EX500</strong>-S 01 )79.468.528.622.254.543.2SI unit forSV series2. SI unit for VQC series valves( <strong>EX500</strong>-Q 01 )PWRCOM2. SI unit for VQC series valves ( <strong>EX500</strong>-Q )80.364.428060122.243.2SI unit forVQC series( <strong>EX500</strong>-Q 01 )( <strong>EX500</strong>-Q 02 )10.5Common to <strong>EX500</strong>-S01/<strong>EX500</strong>-QPWRCOMseriesNo.NameApplication1 Communication Connects the branch cable to Input unit ( branch cableconnector "C1" or "0" with M12 connector ). ( Note1 )2 Communication Connects the branch cable from GW unit ( branchconnector "C2" or "1" cable with M12 connector ). ( Note1 )6680.364.43603 Power LEDIndicates the power supply status. ( Note2 )4 Communication LED Indicates the communication status with GW unit: ( Note2 )60431Note1: For wiring method, refer to subsection "Wiring" ( page 10 ) of section "<strong>EX500</strong>" in thismanual.Note2: For display, refer to "Display" ( page 24 ) in section "SI Unit" in this manual.84.8221310.54420 21

Mounting/WiringSpecificationThe mounting and removing methods of SI unit are as shown below.M3 10: 2 pcs.( Hexagon socket head capscrew ( with spring washer ))Note 1Note 2Supply/exhaust blockassemblySI Unit for SV Series Valves ( <strong>EX500</strong>-S 01 )SI Unit for VQC Series Valves ( <strong>EX500</strong>-Q 01 )M3 30: 4 pcs.( Plus-minus slotround head screw )Supply/exhaust blockassemblyNOTEHolding with hand so that there will be no gap between SI unit and Air supply/exhaustblock assembly, tighten the bolts. Be sure to tighten each bolt by specified tighteningtorque. ( Tightening torque: 0.6Nm )For branch wiring method, refer to subsection "Wiring" ( page 10 ) of section "<strong>EX500</strong>"in this manual. As the power to output devices such as solenoid valve is supplied bybranch wiring ( branch cable with M12 connector ), there is no need to supply powerindividually.For mounting/installation methods of solenoid valve, manifold, etc., refer to thecatalogs, instruction manuals, technical data, etc. of each valve series.When connecting general purpose output block only, refer to subsection "Mounting"( page 33 ) of section "EX9 Series General Purpose Output Block" in this manual.1. SI unit for SV series valve ( <strong>EX500</strong>-S 01 )Connected block Solenoid valve ( single, double )Relay output module ( 1-point output, 2- point output )Connected blockstationSupply voltage for blockDouble solenoid valveRelay output module ( 2-point output )Single solenoid valveRelay output module ( 1-point output )22 23ItemDC24VSpecificationSupply current for block 0.65A Max.Current consumption 100mA or less ( at rated voltage )2. SI unit for VQC series valve ( <strong>EX500</strong>-Q )ItemMax. 8 stationsMax. 16 stationsConnected block Solenoid valve ( single, double )General purpose output block ( <strong>EX500</strong>-Q 02 only )Connected blockstationSupply voltage for blockSupply current for blockCurrent consumption3. Applicable valve seriesSpecificationDouble solenoid valveSingle solenoid valveGeneral purpose output block( <strong>EX500</strong>-Q 02 only )DC24V0.75A Max.100mA or less ( at rated voltage )Max. 8 stationsMax. 16 stationsMax. 8 stationsSeriesManifold Inner diameter of applicable cylinder tube ( mm )Cassette Tie-rod 40 50 63 80 100 125SV1000SV2000SV3000 -SV4000 -VQC1000 -VQC2000 -VQC4000 -For detailed specifications of solenoid valve and manifold, refer to the catalogs, instructionmanuals, technical data, etc. of each valve series.

DisplaySI unit for SV series valves ( <strong>EX500</strong>-S 01 )Input Unit Manifold Part NamesThe Input unit manifold consists of Input unit, input block (s), end block and DIN rail.The input block up to 8 can be connected ( 16 points ).Any combination of input blocks ( for M8 connector, M12 connector and 8-pointintegratedtype ) is acceptable.NoteDo not mix sensor input specifications ( PNP and NPN ) .Power LEDCommunication LEDSI unit for VQC series valves ( <strong>EX500</strong>-Q )Communication LEDPower LEDFigure shows the configuration when only input blocks for M8 connector are connected.Common to <strong>EX500</strong>-SDisplayPower LEDCommunicationLED01/<strong>EX500</strong>-QDescriptionLights on: Power to solenoid valves/output is supplied at thespecified voltage.Lights off: Power to solenoid valves/output is not supplied atthe specified voltage. ( Voltage dropped to lowerthan 20V. )Lights on: Receiving data from GWLights off: No received dataNo.Part nameApplication1 Input unitUnit to communicate with GW unit or SI unit.2 CommunicationTo be connected with branch cables from GW unit orconnectorSI unit ( branch cable with M12 connector ) ( Note1 )3 Power LEDIndicates the power supply status. ( Note2 )4 Input blockUnit for sensor signal input.5 Sensor connector Connects with sensor. ( Note1 )6 Indicator LEDIndicates sensor signal status. ( Note2 )7 MarkerTo be used for writing input No. etc.8 End blockComposes the end of Input unit manifold.9 DIN railTo be mounted with Input unit manifold.Note1: For wiring method, refer to subsection "Wiring" ( page 29 ) of section "Input UnitManifold" in this manual.Note2: For display, refer to "Display" ( page 30 ) in section "Input Unit Manifold" in this manual.24 25

Dimensions ( unit: mm )When only input blocks for M8 connector are connectedDIN RailWhen only input blocks for M12 connector are connectedDIN RailL3L2 ( Rail mounting pitch: 12.5 )L1(L4)544.2(7.5)32.239.735603549L3L2 ( Rail mounting pitch: 12.5 )(L4)5L1Stations 1 2 3 4 5 6 7 8L1 [mm]: Rail length 98 110.5 123 135.5 148 160.5 173 185.5L2 [mm]: Mounting pitch 87.5 100 112.5 125 137.5 150 162.5 175L3 [mm]: Manifold length 74 86 98 110 122 134 146 158L4 [mm]12 12 12.5 12.5 13 13 13.5 13.5When only input blocks of 8-point-integrated type are connectedStations 1 2L1 [mm]: Rail length135.5 185.5L2 [mm]: Mounting pitch125 175L3 [mm]: Manifold length110 158L4 [mm]12.5 13.544.2Stations 1 2 3 4 5 6 7 8L1 [mm]: Rail lengthL2 [mm]: Mounting pitchL3 [mm]: Manifold lengthL4 [mm]InstallationConnect each connector of Input unit, input blocks,and end block ( portion indicated by arrow in thefigure to the right ).Holding with hands so that there will be no gapbetween blocks, place the jointed unit and blocks onDIN rail.Tighten the bolts of Input unit and end block tosecure the jointed unit and blocks to DIN rail.Be sure to tighten the bolts by proper tighteningtorque. ( Tightening torque: 0.6Nm )110.5 123 148 173 185.5 210.5 223 248100 112.5 137.5 162.5 175 200 212.5 237.582 102 122 142 162 182 202 22212 12 12.5 12.5 13 13 13.5 13.5(7.5)32.246.926 27

EX9 Series General Purpose Output Block Part Names (continued ) Mounting2. EX9-PE1The mounting and removing methods of each SI unit are as shown below.VQC seriesSupply/exhaust block assembly,end plate R, power block, or otherEX9 series general purpose output blockNo.Part nameSI unit forgeneral purposeoutput block( <strong>EX500</strong>-Q 02 )Dimensions ( unit: mm )1. EX9-OET1/EX9-OET2/EX9-OEP1/EX9-OEP22. EX9-PE1Application1 Power supply connector Unused2 Power input connector Supplies power for output devices. ( Note1 )3 Power LEDIndicates the power supply status. ( Note2 )Note1: For wiring method, refer to subsection "Wiring" ( page 34 ) of section "EX9 SeriesGeneral Purpose Output Block" in this manual.Note2: For display, refer to subsection "Display" ( page 37 ) in section "EX9 Series GeneralPurpose Output Block" in this manual.M3 18 : 2 pcs.( Hexagon socket headcap screw ( with spring washer ))Power block or EX9 seriesgeneral purpose output blockTie-rod: 4 pcs.SI unit for general purposeoutput block ( <strong>EX500</strong>-Q 02 )NOTEHolding with hand so that there will be no gap between units and tighten the bolts.Be sure to tighten each bolt by specified tightening torque.( Tightening torque: 0.6Nm )Dimensions when general purpose output block is connected13PWRCOMPWRL1L2L300000000661111111121.259.843.272.622.22126.721.259.843.280.322.2PWR2126.7L dimensions32 33<strong>EX500</strong>seriesPWR1.5Mounting hole for:M4 placesNo. of output block stations 1 2 3 4 5 6 7 8L1 [mm] 83 104 125 146 167 188 209 230L2 [mm] 72 93 114 135 156 177 198 219L3 [mm] 67 88 109 130 151 172 193 214NoteThe above dimensions show those when one unit of power block ( width: 21mm ) iscombined. For details, refer to the instruction manuals, technical data, etc. of EX9series general purpose output block.

WiringOutput wiringConnect output devices to the output connectors.EX9-OET1/EX9-OET2/EX9-OEP1/EX9-OEP2 output connectorsM12, 5-pin, socketConnector on cable side: Ex; OMRON Corp.,XS2H, XS2G. etc., and Franz Binder GmbH,Series 713 and 763.Model No.Pin No.1EX9-OET2/EX9-OEP2NPN outputOutput connectorNo.0Power supply( DC24V )Output connectorNo.1Power supply( DC24V )EX9-OET1/EX9-OEP1Output connectorNo.0NC1524 3Output connectorNo.12 Output ( OUT1 ) NC Output ( OUT 1 ) NC3 NC NC Power supply( GND )PNP outputNCPower supply( GND )4 Output ( OUT 0 ) Output ( OUT 1 ) Output ( OUT 0 ) Output ( OUT 1 )5 NC NC NC NCTwo outputs are available with only output connector No. 0.NC: Not connectedPower supply wiringWhen combining EX9-OEP1 ( or EX9-OEP2 ) and EX9-PE1 and using external powersupply, connect the power supply to the power input connector of EX9-PE1.When selecting power supply, refer to "Handling precautions" ( page 3 ) in this manual.EX9-PE1 power supply connector No.0M12, 5-pin, reverse key, socketNoteKeep the waterproof cap mounted on power supply connector No.0 while usingEX9-PE1. This connector is prepared supplementarily and not used normally.EX9-PE1 power input connector No.1M12, 5-pin, reverse key, plugCable side: Hans Turck GmbH & Co., WAKW series254325.51114535M122421NOTEMount a waterproof cap to each unused connector. The proper use of waterproof capcan achieve IP65 Enclosure. ( Tightening torque for M12: 0.1Nm )34Power inputconnector No.143Power supplyconnector No.0Pin No. Power input connector No.1 Power supply connector No.0Note: Each signal of connector No.0 is connected to corresponding signal of connector No.1.The pins whose applications are shown in brackets [ ], are prepared supplementarily andnot used normally.34 351Power supply for output devices ( DC24V ) Power supply for output devices ( DC24V )2 Power supply for output devices ( 0V ) [Power supply for output devices ( 0V ) ]345[Power supply for sensor ( DC24V ) ][Power supply for sensor ( 0V ) ]Ground[Power supply for sensor ( DC24V ) ][Power supply for sensor ( 0V ) ][Ground]

Specification1. EX9-OET1/EX9-OET2/ EX9-OEP1/EX9-OEP2ItemModel No.No. of outputpointsOutputmethodInsulationmethodEX9-OET1P-ch MOS-FET( open drain )Optical isolation ( with SI unit )SpecificationEX9-OET2 EX9-OEP1N-ch MOS-FET( open drain )2 points/unitP-ch MOS-FET( open drain )EX9-OEP2N-ch MOS-FET( open drain )Optical isolation ( with this unit )( Note )Note: To be used in combination with EX9-PE1.For detailed specifications, refer to the instruction manuals, technical data, etc. of EX9series general purpose output block.DisplaySettings for display1. EX9-OET1/EX9-OET2/EX9-OEP1/EX9-OEP22. EX9-PE1DisplayDescription0 Lights on: Output ( OUT 0 ) is ON.Lights off: Output ( OUT 0 ) is OFF.1 Lights on: Output ( OUT 1 ) is ON.Lights off: Output ( OUT 1 ) is OFF.2. EX9-PE1ItemSpecificationRated voltage DC24V+10%, -5%Supply current 3A Max.PWRDisplayPWRDescriptionLights on: Power is supplied from external powersupply.Lights off: Power is not supplied from externalpower supply.36 37

OptionBranch cable with M12 connectorFor details, refer to subsection "Wiring" ( page 10 ) in section "<strong>EX500</strong>" in this manual.How to order<strong>EX500</strong>-AC 030 - SSPSCable length (L) Connector specification003 0.3 [m]SSPS Socket side: Straight, Plug side: Straight005 0.5 [m]SAPA Socket side: Angle, Plug side: Angle010 1 [m]030 3 [m]050 5 [m]Power supply connector cableFor details, refer to subsection "Wiring" ( page 10 ) of section "<strong>EX500</strong>" in this manual.How to order<strong>EX500</strong>-AP 050 - SCable length (L) Connector specification010 1 [m] S Straight050 5 [m] A AngleTerminal PlugConnected to C1 ( or 0 ) of SI unit when Input unit manifold is unused. ( If this terminal plugis not used, COM LED of GW unit does not light on. )How to order<strong>EX500</strong>- AC000- S8 2 134765Plug Connector Pin Layout16M1244.7TroubleshootingOverall systemNo.12ItemSolenoid valvedoesn't workSolenoid valve doesn'twork as programmedSolution/Corrective actionCheck the power for solenoid valves/output ( DC24V )is supplied.Check the connection of the branch cable with M12connector to SI unit.Check Power LED and Communication LEDs of SIunit light on.Check the wiring specification for manifold blockassembly and modify the program.3 Power LED ofInput unit is blinkingShort circuit of input sensor due to failure etc. ispossibly caused. Check the sensor.A current larger than specified value is flowingthrough the power line for input and controllingGW/SI. Check the power supply section.4 No signal is input even Check the power for input and controlling GW/SIthough connected with ( DC24V ) is supplied.sensor(s)Check indicator LED of each block lights on.5 COM A - D LEDdoesn't light onCheck Input unit is connected to the branch of unlitCOM port, and the branch cable with M12 connectoris connected to the Input unit.When connecting no Input unit, connect a terminalplug.Waterproof capMounted on unused ports of GW unit, input block, power block and output block.The proper use of this waterproof cap can achieve IP65 Enclosure. ( The waterproof capsare delivered together with each input block as accessories. )How to order<strong>EX500</strong>-AWConnector specificationES M8 connector ( socket ) /10 pcs.TP M12 connector ( plug ) /1 pc.TS M12 connector ( socket ) /10 pcs.NOTETighten the waterproof cap by the specified tightening torque. ( 0.05Nm for M8,0.1Nm for M12 )38 39

Troubleshooting (continued )No.PROFIBUS-DP compatible communicationItemSolution/Corrective action1 RUN LED is unlit. Check the power for input and control ( DC24V ) issupplied.2 BF LED is lit.Check the signal line from PLC is connected correctly.Check the wiring and pin Nos.Check the address setting is correct.Check the bus terminator setting.3 DIA LED is lit.Check the power for solenoid valves/output ( DC24V )is supplied.Check the power supply voltage for solenoidvalves/output doesn’t drop under 20V.4 SOL LED is unlit. Check the power for solenoid valves/output ( DC24V )is supplied.Check the power supply voltage for solenoidvalves/output doesn’t drop under 20V.Appendix TableCable with PROFIBUS-DP communication connectorManufacturerHans Turck GmbH & Co.KGBRADHARRISONRSSW-RKSW-BB5SB05SPP4PP4ModelFor details or catalog information of communication cable, contact the manufacturer of eachcable.40 41