Made-to-Order Sprockets - Tsubaki

Made-to-Order Sprockets - Tsubaki

Made-to-Order Sprockets - Tsubaki

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

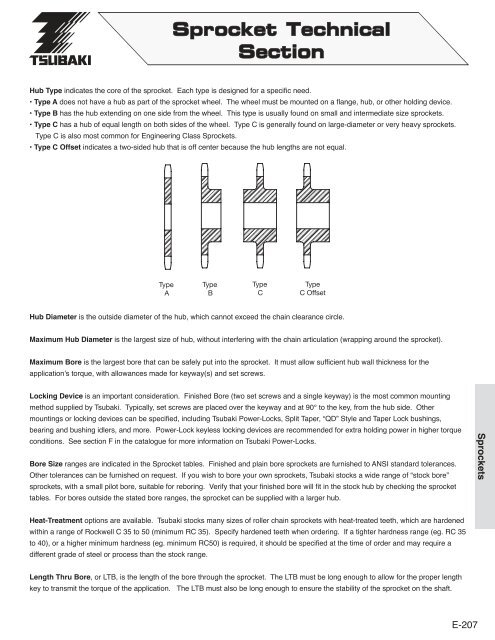

Sprocket TechnicalSectionHub Type indicates the core of the sprocket. Each type is designed for a specific need.• Type A does not have a hub as part of the sprocket wheel. The wheel must be mounted on a flange, hub, or other holding device.• Type B has the hub extending on one side from the wheel. This type is usually found on small and intermediate size sprockets.• Type C has a hub of equal length on both sides of the wheel. Type C is generally found on large-diameter or very heavy sprockets.Type C is also most common for Engineering Class <strong>Sprockets</strong>.• Type C Offset indicates a two-sided hub that is off center because the hub lengths are not equal.Type TypeTypeTypeA BC C OffsetHub Diameter is the outside diameter of the hub, which cannot exceed the chain clearance circle.Maximum Hub Diameter is the largest size of hub, without interfering with the chain articulation (wrapping around the sprocket).Maximum Bore is the largest bore that can be safely put in<strong>to</strong> the sprocket. It must allow sufficient hub wall thickness for theapplication’s <strong>to</strong>rque, with allowances made for keyway(s) and set screws.Locking Device is an important consideration. Finished Bore (two set screws and a single keyway) is the most common mountingmethod supplied by <strong>Tsubaki</strong>. Typically, set screws are placed over the keyway and at 90° <strong>to</strong> the key, from the hub side. Othermountings or locking devices can be specified, including <strong>Tsubaki</strong> Power-Locks, Split Taper, “QD” Style and Taper Lock bushings,bearing and bushing idlers, and more. Power-Lock keyless locking devices are recommended for extra holding power in higher <strong>to</strong>rqueconditions. See section F in the catalogue for more information on <strong>Tsubaki</strong> Power-Locks.Bore Size ranges are indicated in the Sprocket tables. Finished and plain bore sprockets are furnished <strong>to</strong> ANSI standard <strong>to</strong>lerances.Other <strong>to</strong>lerances can be furnished on request. If you wish <strong>to</strong> bore your own sprockets, <strong>Tsubaki</strong> s<strong>to</strong>cks a wide range of “s<strong>to</strong>ck bore”sprockets, with a small pilot bore, suitable for reboring. Verify that your finished bore will fit in the s<strong>to</strong>ck hub by checking the sprockettables. For bores outside the stated bore ranges, the sprocket can be supplied with a larger hub.<strong>Sprockets</strong>Heat-Treatment options are available. <strong>Tsubaki</strong> s<strong>to</strong>cks many sizes of roller chain sprockets with heat-treated teeth, which are hardenedwithin a range of Rockwell C 35 <strong>to</strong> 50 (minimum RC 35). Specify hardened teeth when ordering. If a tighter hardness range (eg. RC 35<strong>to</strong> 40), or a higher minimum hardness (eg. minimum RC50) is required, it should be specified at the time of order and may require adifferent grade of steel or process than the s<strong>to</strong>ck range.Length Thru Bore, or LTB, is the length of the bore through the sprocket. The LTB must be long enough <strong>to</strong> allow for the proper lengthkey <strong>to</strong> transmit the <strong>to</strong>rque of the application. The LTB must also be long enough <strong>to</strong> ensure the stability of the sprocket on the shaft.E-207