- Page 2 and 3:

Made-to-Order SprocketsOur Capabili

- Page 4 and 5:

Made-to-Order SprocketsEngineering

- Page 6 and 7:

Made-to-Order SprocketsBore Options

- Page 8 and 9:

Made-to-Order SprocketsSplit Sprock

- Page 10 and 11:

Made-to-Order SprocketsSegmental Ri

- Page 12 and 13:

Roller ChainSprocket Part NumbersHo

- Page 14 and 15:

No.25Stock Bore1/4” PitchAll dime

- Page 16 and 17:

No.35Stock Bore3/8” PitchSprocket

- Page 18 and 19:

No.35Stainless Steel3/8” PitchAll

- Page 20 and 21:

No.35Single/Double“Taper-Lock”

- Page 22 and 23:

No.35Split Taper3/8” PitchAll dim

- Page 24 and 25:

No.41Finished Bore1/2” PitchAll d

- Page 26 and 27:

No.41“QD” Style1/2” PitchAll

- Page 28 and 29:

No.40Stock Bore1/2” PitchAll dime

- Page 30 and 31:

No.40Finished Bore1/2” PitchSproc

- Page 32 and 33:

No.40Multiple Strand1/2” PitchAll

- Page 34 and 35:

No.40Single“Taper-Lock” Style1/

- Page 36 and 37:

No.40“QD” Style1/2” PitchAll

- Page 38 and 39:

No.40SingleSplit Taper1/2” PitchA

- Page 40 and 41:

No.40TripleSplit Taper1/2” PitchA

- Page 42 and 43:

No.50Stock Bore5/8” PitchAll dime

- Page 44 and 45:

No.50Stainless Steel5/8” PitchAll

- Page 46 and 47:

No.50Double Single5/8” PitchSTOCK

- Page 48 and 49:

No.50Double“Taper-Lock” Style5/

- Page 50 and 51:

No.50SingleSplit Taper5/8” PitchA

- Page 52 and 53:

No.50SingleSplit Taper5/8” PitchA

- Page 54 and 55:

No.50TripleSplit Taper5/8” PitchA

- Page 56 and 57:

No.60Stock Bore3/4” PitchSprocket

- Page 58 and 59:

No.60Stainless Steel3/4” PitchAll

- Page 60 and 61:

No.60Double Single3/4” PitchSTOCK

- Page 62 and 63:

No.60Double“Taper-Lock” Style3/

- Page 64 and 65:

No.60SingleSplit Taper3/4” PitchS

- Page 66 and 67:

No.60DoubleSplit Taper3/4” PitchA

- Page 68 and 69:

No.80Stock Bore1” PitchAll dimens

- Page 70 and 71:

E-70SprocketsFinished Bore1” Pitc

- Page 72 and 73:

No.80Multiple Strand1” PitchAll d

- Page 74 and 75:

No.80Single“Taper-Lock” Style1

- Page 76 and 77:

FFFNo.80“QD” Style1” PitchSpr

- Page 78 and 79:

No.80SingleSplit Taper1” PitchAll

- Page 80 and 81:

No.80TripleSplit Taper1” PitchAll

- Page 82 and 83:

No.100Finished Bore1 1/4” PitchAl

- Page 84 and 85:

No.100Double Single1 1/4” PitchST

- Page 86 and 87:

No.100“QD” Style1 1/4” PitchA

- Page 88 and 89:

No.100DoubleSplit Taper1 1/4” Pit

- Page 90 and 91:

No.120Multiple Strand1 1/2” Pitch

- Page 92 and 93:

No.120“QD” Style1 1/2” PitchA

- Page 94 and 95:

No.120DoubleSplit Taper1 1/2” Pit

- Page 96 and 97:

No.140Multiple Strand1 3/4” Pitch

- Page 98 and 99:

FFFFNo.140“QD” Style1 3/4” Pi

- Page 100 and 101:

No.160Stock Bore2” PitchAll dimen

- Page 102 and 103:

No.160Single“Taper-Lock” Style2

- Page 104 and 105:

No.160Split Taper2” PitchAll dime

- Page 106 and 107:

No.200Stock Bore2 1/2” PitchAll d

- Page 108 and 109:

No.200Split Taper2 1/2” PitchAll

- Page 110 and 111:

No.2040Double Pitch1” Pitch Doubl

- Page 112:

No.2050Double Pitch1 1/4” Pitch D

- Page 115 and 116:

Double Pitch1 1/2” PitchNo.2062 D

- Page 117 and 118:

Double Pitch2” Pitch No.2082 Doub

- Page 119 and 120:

Idler Sprockets &Chain TensionersAd

- Page 121 and 122:

BS/DINStock Bore3/8” PitchNo.06BA

- Page 123 and 124:

BS/DINStock Bore1/2” PitchNo.08BA

- Page 125 and 126:

BS/DINStock Bore5/8” PitchNo.10BA

- Page 127 and 128:

BS/DINStock Bore3/4” PitchNo.12BA

- Page 129 and 130:

BS/DINStock Bore1” PitchNo.16BAll

- Page 131 and 132:

BS/DINStock Bore1 1/4” PitchNo.20

- Page 133 and 134:

BS/DINStock Bore1 1/2” PitchNo.24

- Page 135 and 136:

BS/DINStock Bore2” PitchNo.32BAll

- Page 137 and 138:

“Taper-Lock” Style Bushings3535

- Page 139 and 140:

Split Taper BushingsType 1G & H Bus

- Page 141 and 142:

“XT” Style Bushings“XT” sty

- Page 143 and 144:

“QD” Style Weld-On HubsTsubaki

- Page 145 and 146:

“XT” Style Weld-On Hubs“XT”

- Page 147 and 148:

Flexible Chain Couplings Coupling C

- Page 149 and 150:

Engineering ClassSprocketsChains an

- Page 151 and 152:

Drive ChainSprocketsSprocket Number

- Page 153 and 154:

Drive ChainSprocketsSprocket Number

- Page 155 and 156:

Drive ChainSprocketsSprocket Number

- Page 157 and 158:

Drive ChainSprocketsSprocket Number

- Page 159 and 160:

Roller ConveyorChain SprocketsSproc

- Page 161 and 162:

Roller ConveyorChain SprocketsSproc

- Page 163 and 164:

Roller ConveyorChain SprocketsSproc

- Page 165 and 166:

Roller ConveyorChain SprocketsSproc

- Page 167 and 168: Roller ConveyorChain SprocketsSproc

- Page 169 and 170: Roller ConveyorChain SprocketsSproc

- Page 171 and 172: Roller ConveyorChain SprocketsSproc

- Page 173 and 174: Roller ConveyorChain SprocketsSproc

- Page 175 and 176: Roller ConveyorChain SprocketsSproc

- Page 177 and 178: Roller ConveyorChain SprocketsSproc

- Page 179 and 180: Steel BushedChain SprocketsSprocket

- Page 181 and 182: Steel BushedChain SprocketsSprocket

- Page 183 and 184: Steel BushedChain SprocketsSprocket

- Page 185 and 186: Welded SteelChain SprocketsSprocket

- Page 187 and 188: Welded SteelChain SprocketsSprocket

- Page 189 and 190: Welded SteelChain SprocketsSprocket

- Page 191 and 192: Welded SteelChain SprocketsSprocket

- Page 193 and 194: Asphalt InclineChain SprocketsSproc

- Page 195 and 196: Drop Forged RivetlessChain Sprocket

- Page 197 and 198: ACR Type CollectorTank SprocketsACR

- Page 199 and 200: JAC Type Bar ScreenSprocketsJAC1015

- Page 201 and 202: ACS Type Heavy DutyCollector Tank S

- Page 203 and 204: ACS Type Heavy DutyCollector Tank S

- Page 205 and 206: Sprocket TechnicalSectionSpecific i

- Page 207 and 208: Sprocket TechnicalSectionHub Type i

- Page 209 and 210: Sprocket TechnicalSection180Suggest

- Page 211 and 212: Sprocket TechnicalSectionSprocket S

- Page 213 and 214: Sprocket TechnicalSectionOther Fact

- Page 215 and 216: Sprocket TechnicalSectionTable 7 -

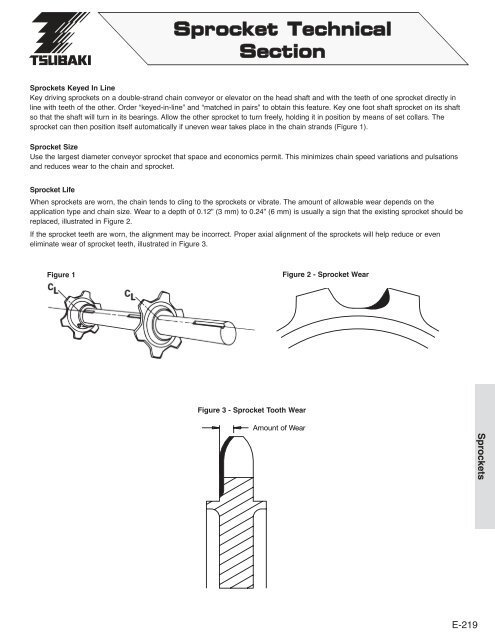

- Page 217: Sprocket TechnicalSectionSprocket H

- Page 221 and 222: Universal ProductCross-ReferenceThi

- Page 223 and 224: Universal ProductCross-ReferenceCha

- Page 225 and 226: Universal ProductCross-ReferenceCha

- Page 227 and 228: Universal ProductCross-ReferenceCha

- Page 229 and 230: Universal ProductCross-ReferenceCha

- Page 231 and 232: Universal ProductCross-ReferenceCha

- Page 233 and 234: Universal ProductCross-ReferenceCha

- Page 235 and 236: Universal ProductCross-ReferenceCha

- Page 237: Universal ProductCross-ReferenceCha