Sprocket TechnicalSectionTable 8 - Hub Diameter Selection TableAll dimensions are in inches unless otherwise specified.Standard Hub Diameters for Steel <strong>Sprockets</strong>Allowable Torque in Inch Pounds and Hub ClassBore of WheelSq. Key SizeSet Screw Size5001,0002,0003,5005,6008,50012,50017,00023,00030,000A B C D E F G H I J K L M N O P Q R S TDiameter of Keyseated Hubs38,00047,00060,00070,000100,000140,000190,000245,000325,000400,000500,000600,000720,000850,0001,000,0001,250,000U V W X Y ZMinimum Hubsfor Loose or Set-Screwed <strong>Sprockets</strong>Dia.Lgth.<strong>Sprockets</strong>15⁄161⁄41 3 ⁄16 1⁄41 7 ⁄16 3⁄81 11 ⁄16 3⁄81 15 ⁄16 1⁄22 3 ⁄16 1⁄22 7 ⁄16 5⁄82 11 ⁄16 5⁄82 15 ⁄16 3⁄43 1 ⁄16 3⁄43 7 ⁄16 7⁄83 11 ⁄16 7⁄83 15 ⁄16 14 7 ⁄16 14 15 ⁄16 1 1 ⁄43⁄8 1 3 ⁄4 1 3 ⁄43⁄8 2 2 23⁄8 2 1 ⁄4 2 1 ⁄4 2 1 ⁄2 2 3 ⁄43⁄8 2 3 ⁄4 2 3 ⁄4 2 3 ⁄4 3 31⁄2 3 3 3 3 1 ⁄4 3 1 ⁄4 3 1 ⁄41⁄2 3 1 ⁄4 3 1 ⁄4 3 1 ⁄4 3 1 ⁄2 3 1 ⁄2 3 1 ⁄2 3 3 ⁄45⁄8 3 3 ⁄4 3 3 ⁄4 3 3 ⁄4 3 3 ⁄4 4 4 4 1 ⁄4 4 1 ⁄45⁄8 4 1 ⁄4 4 1 ⁄4 4 1 ⁄4 4 1 ⁄4 4 1 ⁄4 4 1 ⁄4 4 1 ⁄2 4 1 ⁄2 4 1 ⁄25⁄8 4 1 ⁄2 4 1 ⁄2 4 1 ⁄2 4 1 ⁄2 4 1 ⁄2 4 3 ⁄4 4 3 ⁄4 4 3 ⁄4 5 55⁄8 4 3 ⁄4 4 3 ⁄4 4 3 ⁄4 4 3 ⁄4 4 3 ⁄4 5 5 5 5 1 ⁄4 5 1 ⁄4 5 1 ⁄43⁄4 5 1 ⁄4 5 1 ⁄4 5 1 ⁄4 5 1 ⁄4 5 1 ⁄4 5 1 ⁄4 5 1 ⁄4 5 1 ⁄4 5 1 ⁄2 5 1 ⁄2 5 3 ⁄4 5 3 ⁄43⁄4 5 1 ⁄2 5 1 ⁄2 5 1 ⁄2 5 1 ⁄2 5 1 ⁄2 5 1 ⁄2 5 3 ⁄4 5 3 ⁄4 6 63⁄4 6 6 6 6 6 6 1 ⁄4 6 1 ⁄4 6 1 ⁄2 6 1 ⁄23⁄4 6 1 ⁄2 6 1 ⁄2 6 1 ⁄2 6 1 ⁄2 6 3 ⁄4 6 3 ⁄4 7 77⁄8 7 1 ⁄4 7 1 ⁄4 7 1 ⁄4 7 1 ⁄4 7 1 ⁄4 7 1 ⁄2 7 1 ⁄25 7 ⁄16 1 1 ⁄4 7⁄8 8 8 8 8 8 85 15 ⁄16 1 1 ⁄2 1 9 9 9 9 96 1 ⁄2 1 1 ⁄2 1 9 1 ⁄2 9 1 ⁄2 9 1 ⁄2 9 1 ⁄27 1 1 ⁄2 1 10 10 107 1 ⁄2 1 3 ⁄4 1 1 ⁄4 11 118 1 3 ⁄4 1 1 ⁄4 11 1 ⁄28 1 ⁄2 1 3 ⁄4 1 1 ⁄4 Chain and sprockets will9 1 3 ⁄4 1 1 ⁄4 not transmit full <strong>to</strong>rque9 1 ⁄2 1 3 ⁄4 1 1 ⁄4value of shaft10 2 1 1 ⁄4LengthThroughBore*Hubs on one side only.1 1 *⁄4 1 1 *⁄2 1 3 ⁄4 2 2 1 ⁄2 2 3 ⁄4 3 1 ⁄4 3 1 ⁄2 4 4 1 ⁄4 4 1 ⁄2 5Notes1. The diagonal solid block of figures on the Hub DiameterSelection Table (Table 8) represent a condition of balancebetween <strong>to</strong>rque and keyway with bore sizes. When the hubclass requirements and the bore size intersect in the blankspace below and <strong>to</strong> the left of the solid block, it indicates thatchain and sprocket will not transmit the full <strong>to</strong>rque value ofthe keyed shaft. When the hub class and the bore sizeintersect above and <strong>to</strong> the right of the solid block, it indicatesChain and sprockets arestronger than shafts1 3 ⁄422 1 ⁄42 3 ⁄433 1 ⁄43 3 ⁄44 1 ⁄44 1 ⁄24 3 ⁄46 5 1 ⁄26 1 ⁄2 6 1 ⁄2 67 7 7 6 1 ⁄27 1 ⁄2 8 8 8 7 1 ⁄48 8 1 ⁄2 8 1 ⁄2 8 1 ⁄2 8 1 ⁄2 89 9 1 ⁄2 9 1 ⁄2 9 1 ⁄2 9 1 ⁄2 9 1 ⁄2 99 1 ⁄2 10 10 10 10 10 10 9 1 ⁄210 10 1 ⁄2 10 1 ⁄2 10 1 ⁄2 10 1 ⁄2 10 1 ⁄2 10 1 ⁄2 11 1011 11 1 ⁄2 11 1 ⁄2 11 1 ⁄2 11 1 ⁄2 11 1 ⁄2 11 1 ⁄2 12 12 1111 1 ⁄2 12 12 12 12 12 12 12 1 ⁄2 12 1 ⁄2 12 1 ⁄2 11 1 ⁄212 12 1 ⁄2 12 1 ⁄2 12 1 ⁄2 12 1 ⁄2 12 1 ⁄2 12 1 ⁄2 13 13 13 13 1 ⁄2 1213 13 13 13 13 13 13 1 ⁄2 13 1 ⁄2 13 1 ⁄2 14 14 1313 1 ⁄2 13 1 ⁄2 13 1 ⁄2 13 1 ⁄2 13 1 ⁄2 14 14 14 14 1 ⁄2 14 1 ⁄2 15 13 1 ⁄214 1 ⁄2 14 1 ⁄2 14 1 ⁄2 14 1 ⁄2 15 15 15 15 1 ⁄2 15 1 ⁄2 16 16 14 1 ⁄25 1 ⁄4 5 1 ⁄2 6 6 1 ⁄2 7 7 3 ⁄4 8 1 ⁄2 9 1 ⁄2 10 10 1 ⁄2 11 11 1 ⁄2 12 12 1 ⁄2that chain and sprocket are stronger than the keyed shaft. TheHub Diameter Selection Table also serves as a design checkon the shaft sizes as well.2. For loose-fitting sprockets only (no keyway or set screw),the minimum hub diameter and length are shown at theright end of the shaft size row and at the bot<strong>to</strong>m of thehub class columns.5 1 ⁄4Length is determined same as for Key-seated <strong>Sprockets</strong>E-216

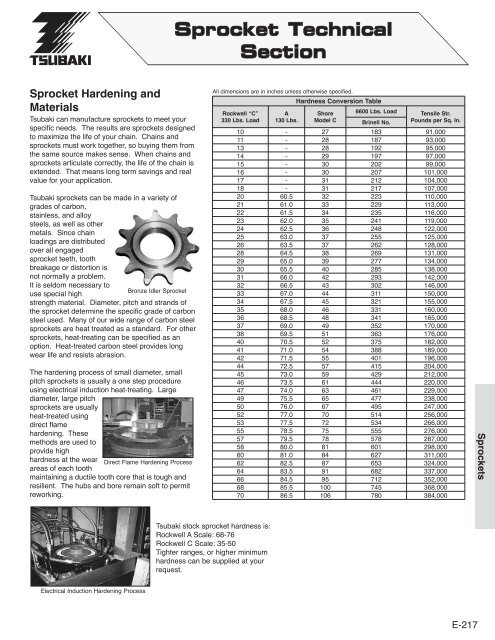

Sprocket TechnicalSectionSprocket Hardening andMaterials<strong>Tsubaki</strong> can manufacture sprockets <strong>to</strong> meet yourspecific needs. The results are sprockets designed<strong>to</strong> maximize the life of your chain. Chains andsprockets must work <strong>to</strong>gether, so buying them fromthe same source makes sense. When chains andsprockets articulate correctly, the life of the chain isextended. That means long term savings and realvalue for your application.<strong>Tsubaki</strong> sprockets can be made in a variety ofgrades of carbon,stainless, and alloysteels, as well as othermetals. Since chainloadings are distributedover all engagedsprocket teeth, <strong>to</strong>othbreakage or dis<strong>to</strong>rtion isnot normally a problem.It is seldom necessary <strong>to</strong>use special highBronze Idler <strong>Sprockets</strong>trength material. Diameter, pitch and strands ofthe sprocket determine the specific grade of carbonsteel used. Many of our wide range of carbon steelsprockets are heat treated as a standard. For othersprockets, heat-treating can be specified as anoption. Heat-treated carbon steel provides longwear life and resists abrasion.The hardening process of small diameter, smallpitch sprockets is usually a one step procedureusing electrical induction heat-treating. Largediameter, large pitchsprockets are usuallyheat-treated usingdirect flamehardening. Thesemethods are used <strong>to</strong>provide highhardness at the wear Direct Flame Hardening Processareas of each <strong>to</strong>othmaintaining a ductile <strong>to</strong>oth core that is <strong>to</strong>ugh andresilient. The hubs and bore remain soft <strong>to</strong> permitreworking.All dimensions are in inches unless otherwise specified.Hardness Conversion TableRockwell “C”330 Lbs. Load10111314151617182021222324252628293031323334353637384041424445464749505253555758606264666870A130 Lbs.--------60.561.061.562.062.563.063.564.565.065.566.066.567.067.568.068.569.069.570.571.071.572.573.073.574.075.576.077.077.578.579.580.081.082.583.584.585.586.5ShoreModel C27282829303031313233343536373738394042434445464849515254555759616365677072757881848791951001066600 Lbs. LoadBrinell No.183187192197202207212217223229235241248255262269277285293302311321331341352363375388401415429444461477495514534555578601627653682712745780Tensile Str.Pounds per Sq. In.91,00093,00095,00097,00099,000101,000104,000107,000110,000113,000116,000119,000122,000125,000128,000131,000134,000138,000142,000146,000150,000155,000160,000165,000170,000176,000182,000189,000196,000204,000212,000220,000229,000238,000247,000256,000266,000276,000287,000298,000311,000324,000337,000352,000368,000384,000<strong>Sprockets</strong><strong>Tsubaki</strong> s<strong>to</strong>ck sprocket hardness is:Rockwell A Scale: 68-76Rockwell C Scale: 35-50Tighter ranges, or higher minimumhardness can be supplied at yourrequest.Electrical Induction Hardening ProcessE-217