SHAKAERATOR - Operator Manual - McConnel

SHAKAERATOR - Operator Manual - McConnel

SHAKAERATOR - Operator Manual - McConnel

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

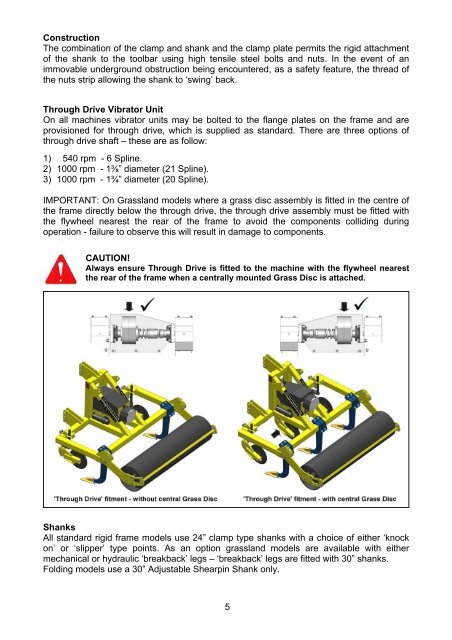

ConstructionThe combination of the clamp and shank and the clamp plate permits the rigid attachmentof the shank to the toolbar using high tensile steel bolts and nuts. In the event of animmovable underground obstruction being encountered, as a safety feature, the thread ofthe nuts strip allowing the shank to ‘swing’ back.Through Drive Vibrator UnitOn all machines vibrator units may be bolted to the flange plates on the frame and areprovisioned for through drive, which is supplied as standard. There are three options ofthrough drive shaft – these are as follow:1) 540 rpm - 6 Spline.2) 1000 rpm - 1⅜” diameter (21 Spline).3) 1000 rpm - 1¾” diameter (20 Spline).IMPORTANT: On Grassland models where a grass disc assembly is fitted in the centre ofthe frame directly below the through drive, the through drive assembly must be fitted withthe flywheel nearest the rear of the frame to avoid the components colliding duringoperation - failure to observe this will result in damage to components.CAUTION!Always ensure Through Drive is fitted to the machine with the flywheel nearestthe rear of the frame when a centrally mounted Grass Disc is attached.ShanksAll standard rigid frame models use 24” clamp type shanks with a choice of either ‘knockon’ or ‘slipper’ type points. As an option grassland models are available with eithermechanical or hydraulic ‘breakback’ legs – ‘breakback’ legs are fitted with 30” shanks.Folding models use a 30” Adjustable Shearpin Shank only.5