SHAKAERATOR - Operator Manual - McConnel

SHAKAERATOR - Operator Manual - McConnel

SHAKAERATOR - Operator Manual - McConnel

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

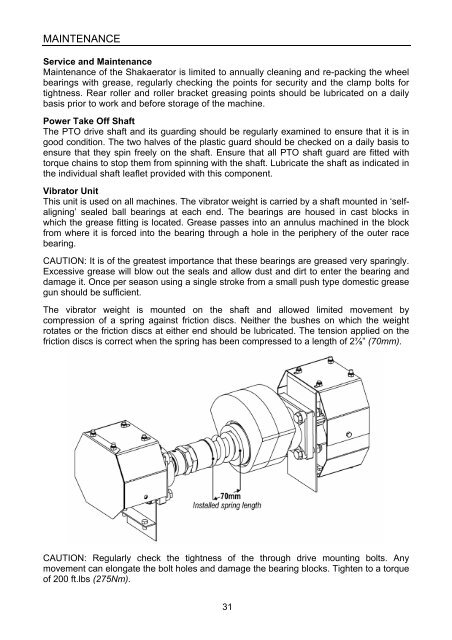

MAINTENANCEService and MaintenanceMaintenance of the Shakaerator is limited to annually cleaning and re-packing the wheelbearings with grease, regularly checking the points for security and the clamp bolts fortightness. Rear roller and roller bracket greasing points should be lubricated on a dailybasis prior to work and before storage of the machine.Power Take Off ShaftThe PTO drive shaft and its guarding should be regularly examined to ensure that it is ingood condition. The two halves of the plastic guard should be checked on a daily basis toensure that they spin freely on the shaft. Ensure that all PTO shaft guard are fitted withtorque chains to stop them from spinning with the shaft. Lubricate the shaft as indicated inthe individual shaft leaflet provided with this component.Vibrator UnitThis unit is used on all machines. The vibrator weight is carried by a shaft mounted in ‘selfaligning’sealed ball bearings at each end. The bearings are housed in cast blocks inwhich the grease fitting is located. Grease passes into an annulus machined in the blockfrom where it is forced into the bearing through a hole in the periphery of the outer racebearing.CAUTION: It is of the greatest importance that these bearings are greased very sparingly.Excessive grease will blow out the seals and allow dust and dirt to enter the bearing anddamage it. Once per season using a single stroke from a small push type domestic greasegun should be sufficient.The vibrator weight is mounted on the shaft and allowed limited movement bycompression of a spring against friction discs. Neither the bushes on which the weightrotates or the friction discs at either end should be lubricated. The tension applied on thefriction discs is correct when the spring has been compressed to a length of 2⅞” (70mm).CAUTION: Regularly check the tightness of the through drive mounting bolts. Anymovement can elongate the bolt holes and damage the bearing blocks. Tighten to a torqueof 200 ft.lbs (275Nm).31