SHAKAERATOR - Operator Manual - McConnel

SHAKAERATOR - Operator Manual - McConnel

SHAKAERATOR - Operator Manual - McConnel

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

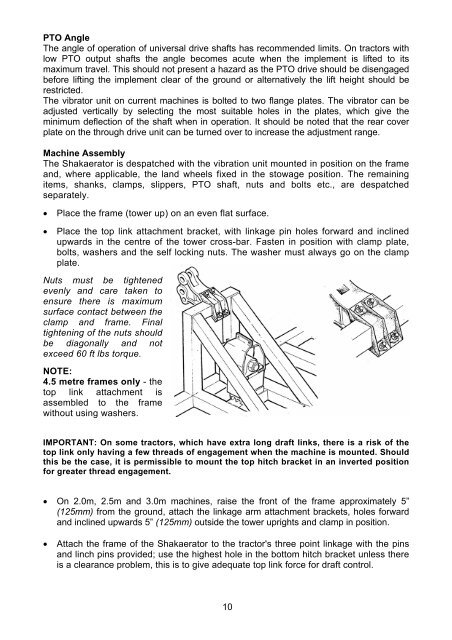

PTO AngleThe angle of operation of universal drive shafts has recommended limits. On tractors withlow PTO output shafts the angle becomes acute when the implement is lifted to itsmaximum travel. This should not present a hazard as the PTO drive should be disengagedbefore lifting the implement clear of the ground or alternatively the lift height should berestricted.The vibrator unit on current machines is bolted to two flange plates. The vibrator can beadjusted vertically by selecting the most suitable holes in the plates, which give theminimum deflection of the shaft when in operation. It should be noted that the rear coverplate on the through drive unit can be turned over to increase the adjustment range.Machine AssemblyThe Shakaerator is despatched with the vibration unit mounted in position on the frameand, where applicable, the land wheels fixed in the stowage position. The remainingitems, shanks, clamps, slippers, PTO shaft, nuts and bolts etc., are despatchedseparately.• Place the frame (tower up) on an even flat surface.• Place the top link attachment bracket, with linkage pin holes forward and inclinedupwards in the centre of the tower cross-bar. Fasten in position with clamp plate,bolts, washers and the self locking nuts. The washer must always go on the clampplate.Nuts must be tightenedevenly and care taken toensure there is maximumsurface contact between theclamp and frame. Finaltightening of the nuts shouldbe diagonally and notexceed 60 ft lbs torque.NOTE:4.5 metre frames only - thetop link attachment isassembled to the framewithout using washers.IMPORTANT: On some tractors, which have extra long draft links, there is a risk of thetop link only having a few threads of engagement when the machine is mounted. Shouldthis be the case, it is permissible to mount the top hitch bracket in an inverted positionfor greater thread engagement.• On 2.0m, 2.5m and 3.0m machines, raise the front of the frame approximately 5”(125mm) from the ground, attach the linkage arm attachment brackets, holes forwardand inclined upwards 5” (125mm) outside the tower uprights and clamp in position.• Attach the frame of the Shakaerator to the tractor's three point linkage with the pinsand linch pins provided; use the highest hole in the bottom hitch bracket unless thereis a clearance problem, this is to give adequate top link force for draft control.10