KR C2 sr - KUKA Robotics

KR C2 sr - KUKA Robotics

KR C2 sr - KUKA Robotics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

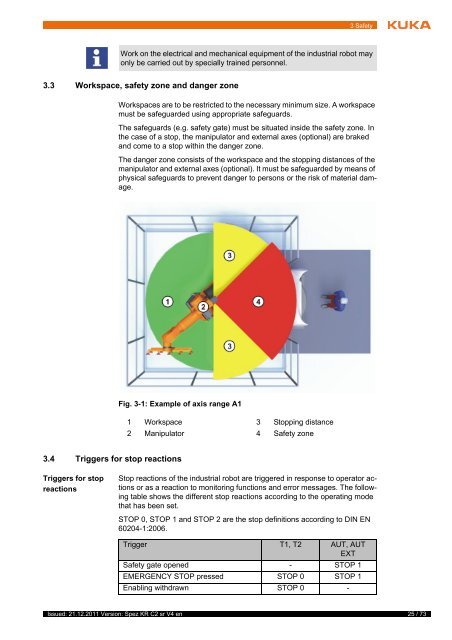

3 SafetyWork on the electrical and mechanical equipment of the industrial robot mayonly be carried out by specially trained personnel.3.3 Workspace, safety zone and danger zoneWorkspaces are to be restricted to the necessary minimum size. A workspacemust be safeguarded using appropriate safeguards.The safeguards (e.g. safety gate) must be situated inside the safety zone. Inthe case of a stop, the manipulator and external axes (optional) are brakedand come to a stop within the danger zone.The danger zone consists of the workspace and the stopping distances of themanipulator and external axes (optional). It must be safeguarded by means ofphysical safeguards to prevent danger to persons or the risk of material damage.Fig. 3-1: Example of axis range A11 Workspace 3 Stopping distance2 Manipulator 4 Safety zone3.4 Triggers for stop reactionsTriggers for stopreactionsStop reactions of the industrial robot are triggered in response to operator actionsor as a reaction to monitoring functions and error messages. The followingtable shows the different stop reactions according to the operating modethat has been set.STOP 0, STOP 1 and STOP 2 are the stop definitions according to DIN EN60204-1:2006.Trigger T1, T2 AUT, AUTEXTSafety gate opened - STOP 1EMERGENCY STOP pressed STOP 0 STOP 1Enabling withdrawn STOP 0 -Issued: 21.12.2011 Version: Spez <strong>KR</strong> <strong>C2</strong> <strong>sr</strong> V4 en25 / 73